A kind of cross-linking type blended color fixing agent and its preparation and use method

A color-fixing agent and cross-linking technology, applied in the direction of dyeing, textile and paper making, etc., can solve the problems of hard and astringent fabrics, affect the quality of fabrics, and affect the quality of finished products, and achieve improved color fastness and durable finishing. effect, the effect of increasing the molecular weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

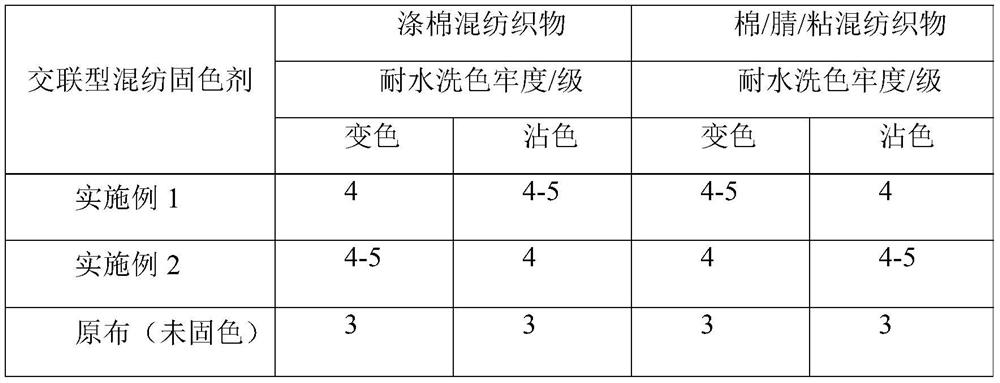

Examples

Embodiment 1

[0036] Provide the following raw materials by weight: 15 parts of allylamine hydrochloride, 12 parts of acrylamide, 40 parts of methacryloxyethyl dimethyl benzyl ammonium chloride, 15 parts of polyether AH-6, no 3 parts of saturated olefin silane coupling agent, 0.006 part of amino trimethylene phosphonic acid, 0.6 part of ammonium persulfate-sodium bisulfite and 40 parts of deionized water.

[0037] In the present embodiment, the preparation process it involves includes the following steps:

[0038] Preparation of metal ion chelating agent solution and initiator solution; wherein in the metal ion chelating agent solution, each component and parts by weight thereof include 0.006 part of metal ion chelating agent, 0.4 part of deionized water; in the described initiator solution, Each component and its parts by weight include 0.6 part of initiator and 25 parts of deionized water.

[0039] Add the allylamine hydrochloride, acrylamide, cationic quaternary ammonium salt monomer, p...

Embodiment 2

[0043] Provide the following raw materials by weight: 25 parts of allylamine hydrochloride, 15 parts of acrylamide, 35 parts of methacryloxyethyl dimethyl benzyl ammonium chloride, 12 parts of polyether AH-6, no 4 parts of saturated olefin silane coupling agent, 0.01 part of amino trimethylene phosphonic acid, 0.8 part of ammonium persulfate-sodium bisulfite and 40 parts of deionized water.

[0044] In the present embodiment, the preparation process it involves includes the following steps:

[0045] Prepare metal ion chelating agent solution and initiator solution; In described metal ion chelating agent solution, each component and parts by weight thereof include 0.01 part of metal ion chelating agent, 0.4 part of deionized water; In described initiator solution, each The components and parts by weight include 0.8 parts of initiator and 25 parts of deionized water.

[0046]Add allylamine hydrochloride; acrylamide; cationic quaternary ammonium salt monomer; polyether AH-6; uns...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com