Wheel change excavator capable of being automatically lubricated and wheel change method thereof

An automatic lubrication and excavator technology, applied in the direction of mechanically driven excavators/dredgers, etc., can solve problems such as damage to the road surface, achieve stable equipment, reasonable mechanism arrangement, and ensure normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

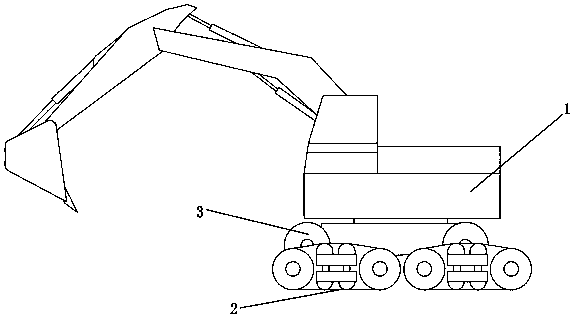

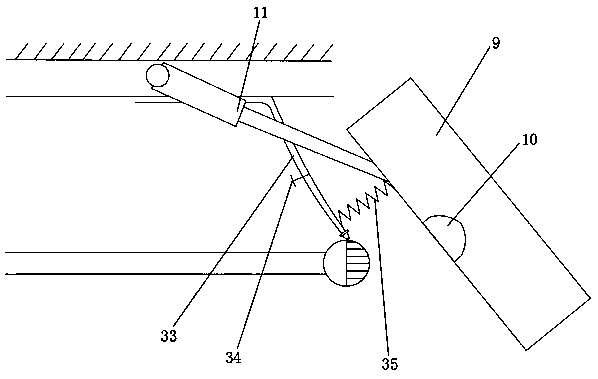

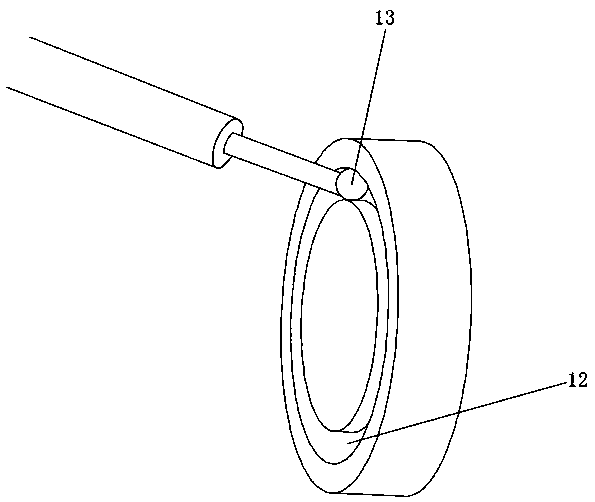

[0036] As shown in the accompanying drawings in the description, a self-lubricating wheel-changing excavator and a method of using the same include an excavator body 1, a crawler track moving mechanism 2, a wheel-type moving mechanism 3, a power connection mechanism 4, an auxiliary support device 25, The automatic lubricating device 28 and the control system; the crawler moving mechanism 2 is divided into four groups, which are arranged at the bottom of the excavator body 1 in the form of two groups in front and two groups in the back, and each group is connected with a "eight"-shaped inclined The hydraulic cylinder I11; the wheeled moving mechanism 3 is provided with a walking wheel 16, a set wheel 17, a bending track 18, a hydraulic cylinder II19, an axle I14 and a helical gear I15; the bending track 18 is fixed on the excavator body 1 and bend downward; the traveling wheel 16 is movably sleeved on the bending track 18 through the sleeve wheel 17; the hydraulic cylinder II 19...

Embodiment 2

[0043] As shown in the accompanying drawings in the description, a self-lubricating wheel-changing excavator and a method of using the same include an excavator body 1, a crawler track moving mechanism 2, a wheel-type moving mechanism 3, a power connection mechanism 4, an auxiliary support device 25, The automatic lubricating device 28 and the control system; the crawler moving mechanism 2 is divided into four groups, which are arranged at the bottom of the excavator body 1 in the form of two groups in front and two groups in the back, and each group is connected with a "eight"-shaped inclined The hydraulic cylinder I11; the wheeled moving mechanism 3 is provided with a walking wheel 16, a set wheel 17, a bending track 18, a hydraulic cylinder II19, an axle I14 and a helical gear I15; the bending track 18 is fixed on the excavator body 1 and bend downward; the traveling wheel 16 is movably sleeved on the bending track 18 through the sleeve wheel 17; the hydraulic cylinder II 19...

Embodiment 3

[0051] As shown in the accompanying drawings in the description, a self-lubricating wheel-changing excavator and a method of using the same include an excavator body 1, a crawler track moving mechanism 2, a wheel-type moving mechanism 3, a power connection mechanism 4, an auxiliary support device 25, The automatic lubricating device 28 and the control system; the crawler moving mechanism 2 is divided into four groups, which are arranged at the bottom of the excavator body 1 in the form of two groups in front and two groups in the back, and each group is connected with a "eight"-shaped inclined The hydraulic cylinder I11; the wheeled moving mechanism 3 is provided with a walking wheel 16, a set wheel 17, a bending track 18, a hydraulic cylinder II19, an axle I14 and a helical gear I15; the bending track 18 is fixed on the excavator body 1 and bend downward; the traveling wheel 16 is movably sleeved on the bending track 18 through the sleeve wheel 17; the hydraulic cylinder II 19...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com