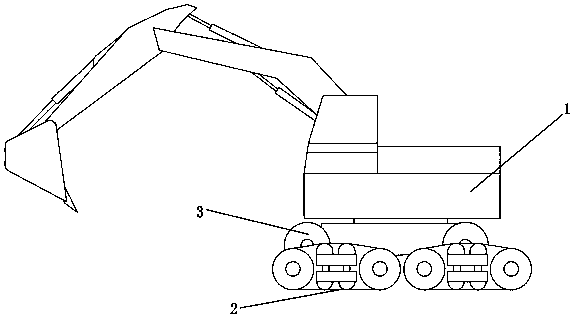

Stable wheel exchange type excavator and wheel exchange method thereof

An excavator and wheeled technology, which is applied in the field of wheel-changing excavators, can solve problems such as damage to the road surface, and achieve the effects of stable equipment, reasonable mechanism arrangement, and load reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1: (no right 3, right 4)

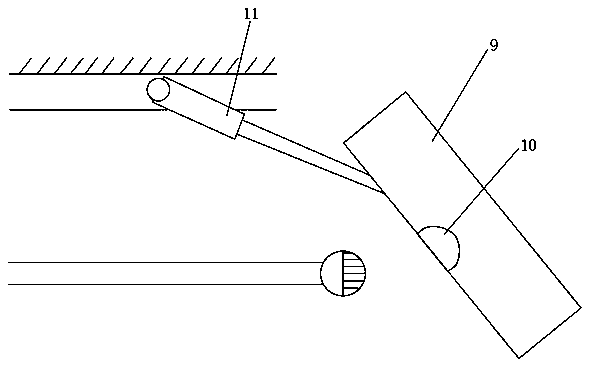

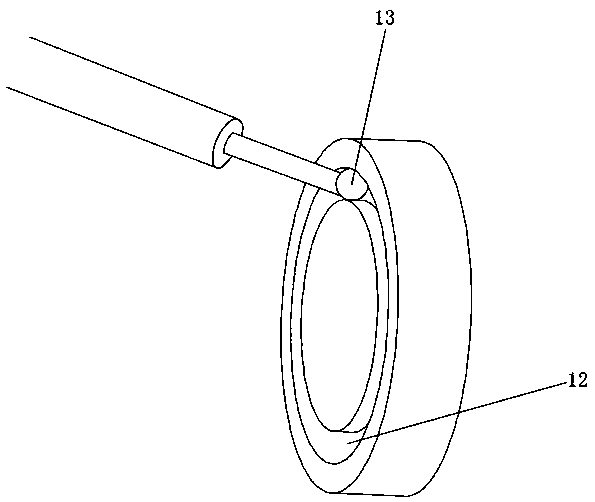

[0035] As shown in the accompanying drawings of the description, a stable wheel-changing excavator and its use method include an excavator body 1, a crawler moving mechanism 2, a wheeled moving mechanism 3, a power connection mechanism 4, an auxiliary support device 25 and a control system ; The track moving mechanism 2 is divided into four groups, with two groups at the front and two groups at the bottom of the excavator body 1, and each group is connected with a "eight"-shaped inclined hydraulic cylinder I11; The wheeled mobile mechanism 3 is provided with a traveling wheel 16, a set wheel 17, a bending track 18, a hydraulic cylinder II 19, a wheel shaft I 14 and a helical gear I 15; the bending track 18 is fixed under the excavator body 1 and is downward Bending; the road wheel 16 is movably socketed on the bending track 18 through the sleeve wheel 17; the hydraulic cylinder II19 is hinged under the excavator body 1, and connects the ...

Embodiment 2

[0040] Example 2: (with right 3, without right 4)

[0041] As shown in the accompanying drawings of the description, a stable wheel-changing excavator and its use method include an excavator body 1, a crawler moving mechanism 2, a wheeled moving mechanism 3, a power connection mechanism 4, an auxiliary support device 25 and a control system ; The track moving mechanism 2 is divided into four groups, with two groups at the front and two groups at the bottom of the excavator body 1, and each group is connected with a "eight"-shaped inclined hydraulic cylinder I11; The wheeled mobile mechanism 3 is provided with a traveling wheel 16, a set wheel 17, a bending track 18, a hydraulic cylinder II 19, a wheel shaft I 14 and a helical gear I 15; the bending track 18 is fixed under the excavator body 1 and is downward Bending; the road wheel 16 is movably socketed on the bending track 18 through the sleeve wheel 17; the hydraulic cylinder II19 is hinged under the excavator body 1, and c...

Embodiment 3

[0047] Example 3: (no right 3, right 4)

[0048] As shown in the accompanying drawings of the description, a stable wheel-changing excavator and its use method include an excavator body 1, a crawler moving mechanism 2, a wheeled moving mechanism 3, a power connection mechanism 4, an auxiliary support device 25 and a control system ; The track moving mechanism 2 is divided into four groups, with two groups at the front and two groups at the bottom of the excavator body 1, and each group is connected with a "eight"-shaped inclined hydraulic cylinder I11; The wheeled mobile mechanism 3 is provided with a traveling wheel 16, a set wheel 17, a bending track 18, a hydraulic cylinder II 19, a wheel shaft I 14 and a helical gear I 15; the bending track 18 is fixed under the excavator body 1 and is downward Bending; the road wheel 16 is movably socketed on the bending track 18 through the sleeve wheel 17; the hydraulic cylinder II19 is hinged under the excavator body 1, and connects th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com