A device and method for measuring the release performance of concrete with a pressure rod

A technology of demoulding performance and concrete is applied in the field of pressure rod-type devices for measuring the demoulding performance of concrete, which can solve the problems of time-consuming and laborious operation, complicated equipment cost, inaccuracy, etc. effect of difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

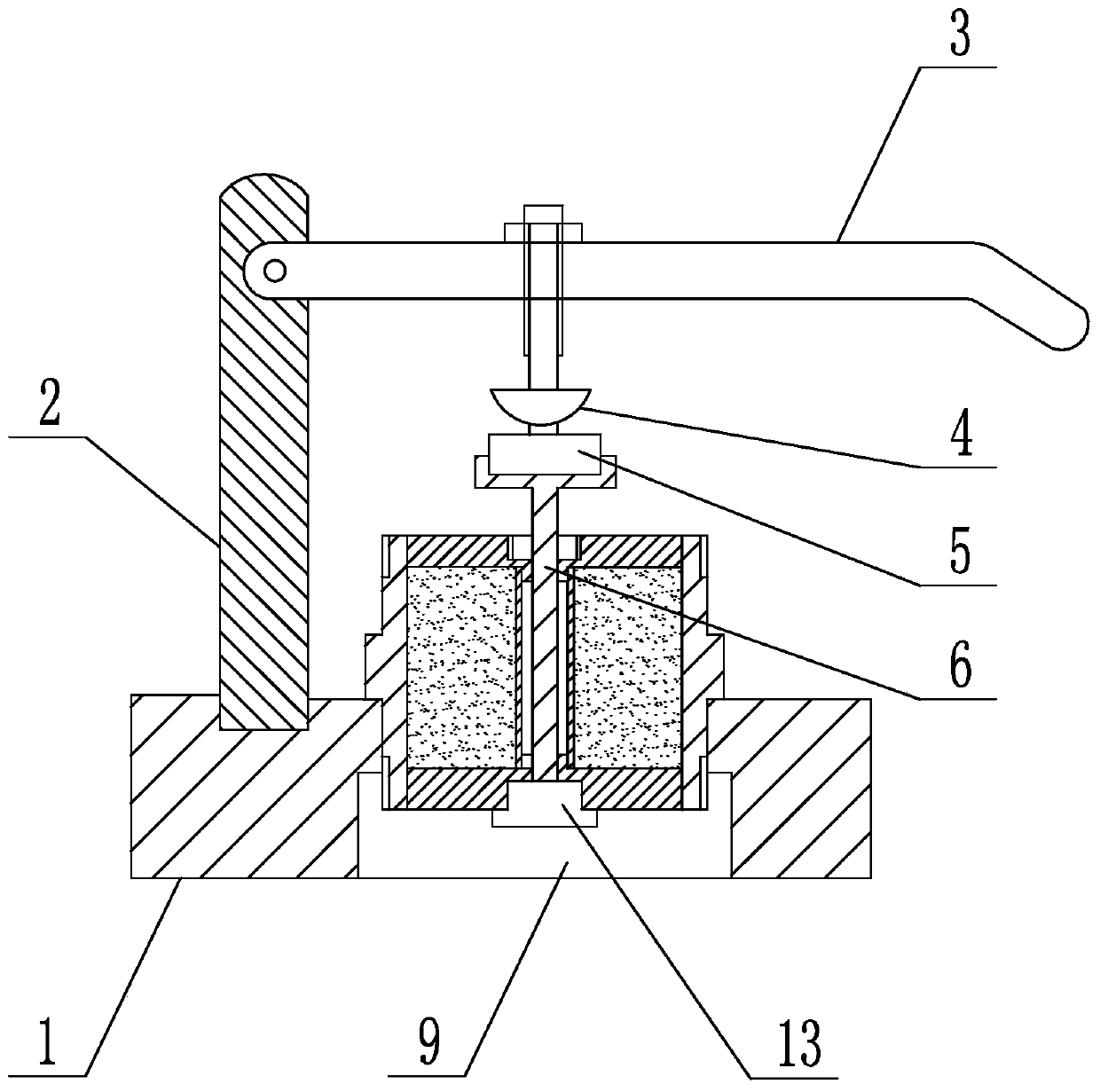

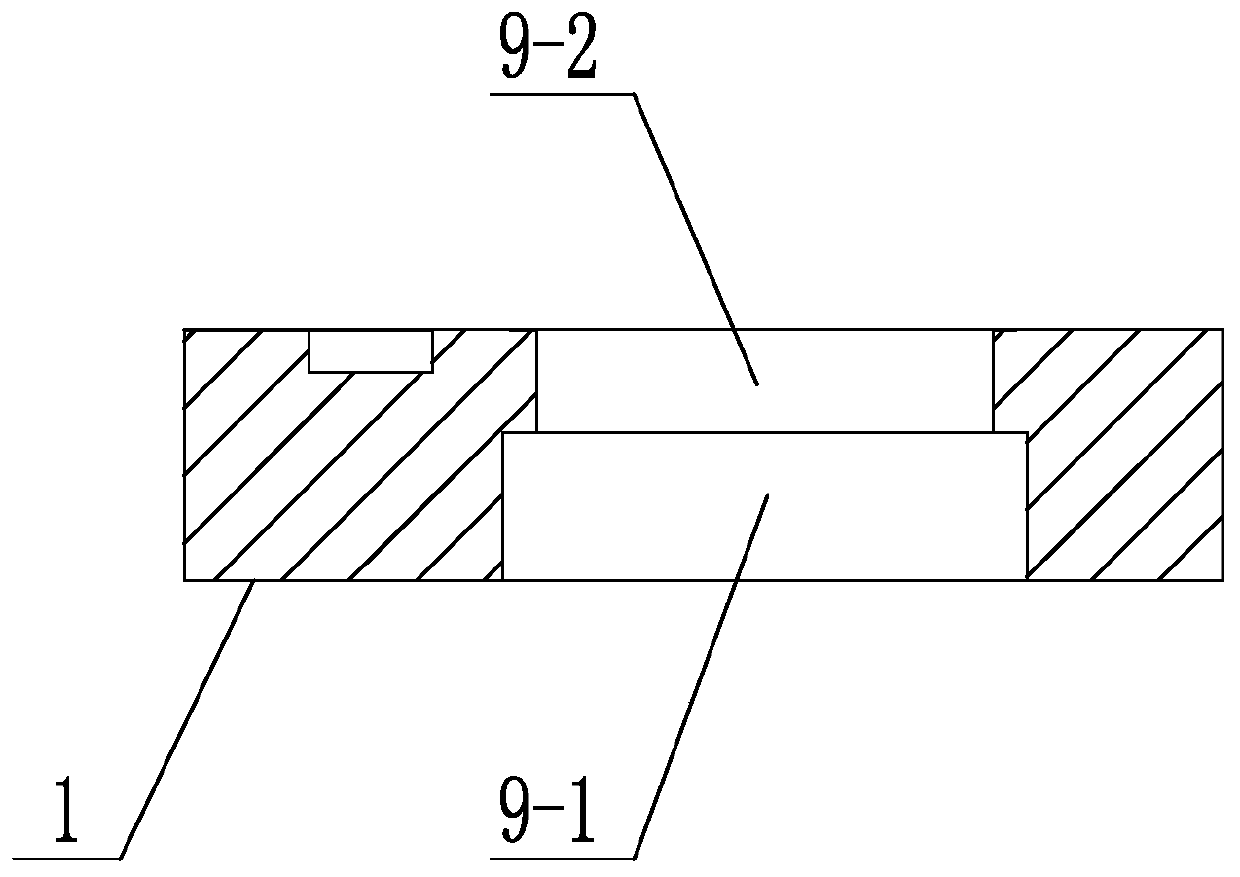

[0026] Specific implementation mode one: combine figure 1 , figure 2 , image 3 and Figure 4 Describe this embodiment, this embodiment comprises base 1, column 2, pressure rod 3, pressure member 4, pressure sensor 5, dowel 6, screw plug 13 and concrete mould, described base 1 is horizontally arranged, and column 2 is vertical It is directly arranged on the base 1 and its lower end is fixedly connected with the base 1. The base 1 is processed with a mounting hole 9 matching the concrete mold. The concrete mold includes an outer casing 8-1, an upper pressing plate 8-2, and a lower pressing plate 8-3. , the inner sleeve 8-4, the upper cover 8-5 and the lower cover 8-6, the outer wall of the outer sleeve 8-1 is provided with a shoulder 10 matched with the mounting hole 9, and the outer sleeve 8-1 passes through the shoulder 10 Clipped on the installation hole 9 of the base 1, the inner casing 8-4 is inside the outer casing 8-1 and the two are arranged coaxially, and concrete ...

specific Embodiment approach 2

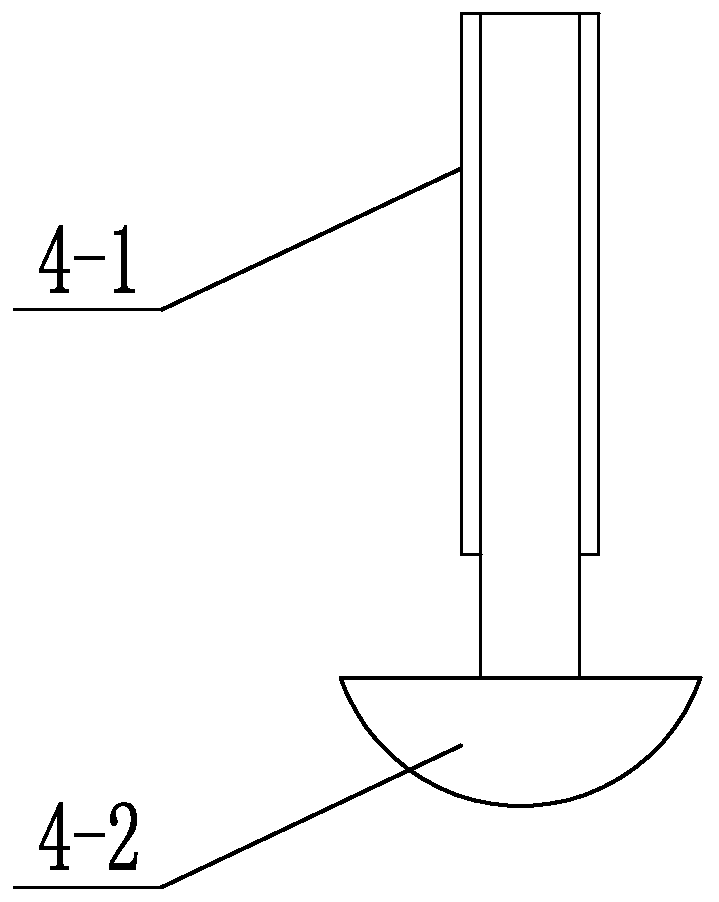

[0030] Embodiment 2: This embodiment is a further limitation of Embodiment 1. The pressure member 4 includes a connecting rod 4-1 and an arc cover 4-2. One end of the connecting rod 4-1 is detachably connected to the pressing rod 3. , the other end of the connecting rod 4-1 is provided with an arc cover 4-2, and the arc-shaped end of the arc cover 4-2 is bent toward the depression bar. The pressure member 4 is arranged as an arc-shaped screw to ensure that the pressure member 4 is always in good contact with the pressure sensor 5 and exerts force downward in the vertical direction when the pressure rod 3 is under force.

specific Embodiment approach 3

[0031] Embodiment 3: This embodiment is a further limitation of Embodiment 1 or 2. The upper platen 8-2 is processed with a first through hole 11 along its thickness direction, and the inner wall of the first through hole 11 is processed with a first internal thread. The lower pressing plate 8-3 is processed with a second through hole 12 along its thickness direction, and the inner wall of the second through hole 12 is processed with a second internal thread, and the outer wall of the plug 13 is processed with a first internal thread and a second internal thread respectively. The screw thread matches the external thread, and the screw plug 13 is detachably connected to the second through hole 12. When the dowel rod 6 passes through the first through hole 11, the upper end of the screw plug 13 is closely attached to the lower end of the dowel rod 6. .

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com