Propagation simulation and permeability test integrated experimental device for true triaxial crack, and method thereof

A technology of crack expansion and experimental equipment, which is applied in the field of rock mechanics and engineering, and can solve problems such as cumbersome operation, complex structure, and difficulty in rock permeability testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

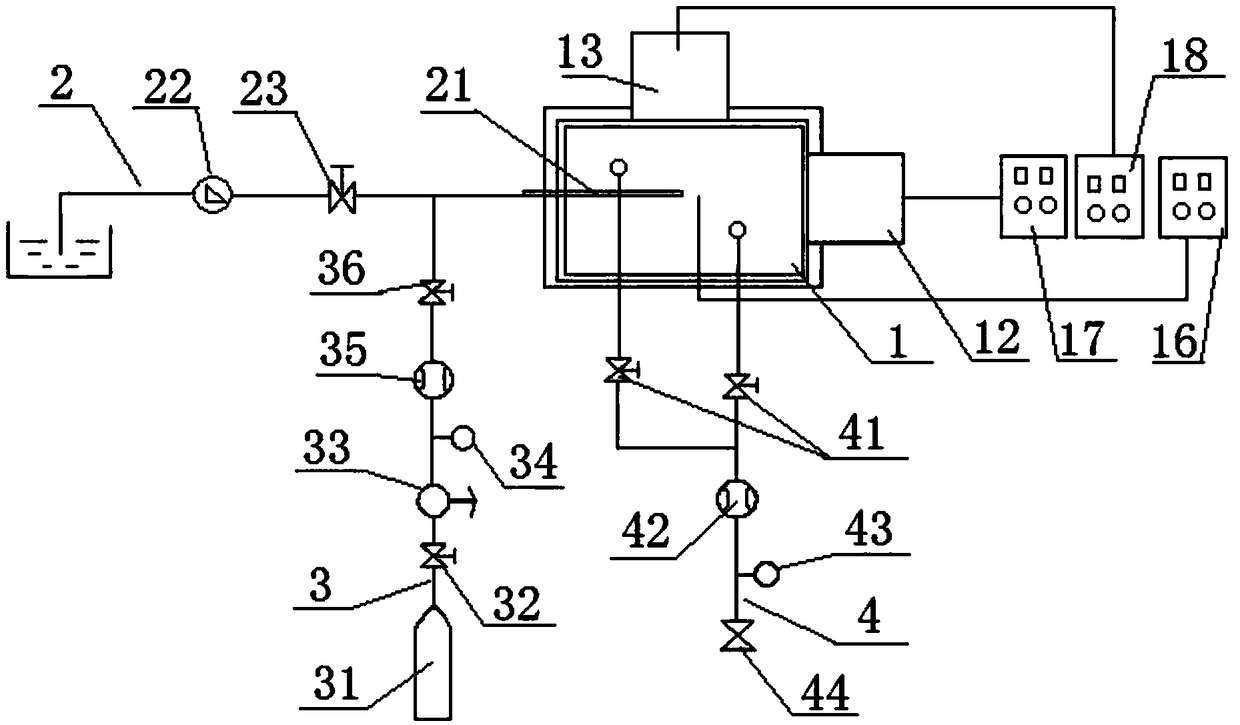

Method used

Image

Examples

Embodiment 1

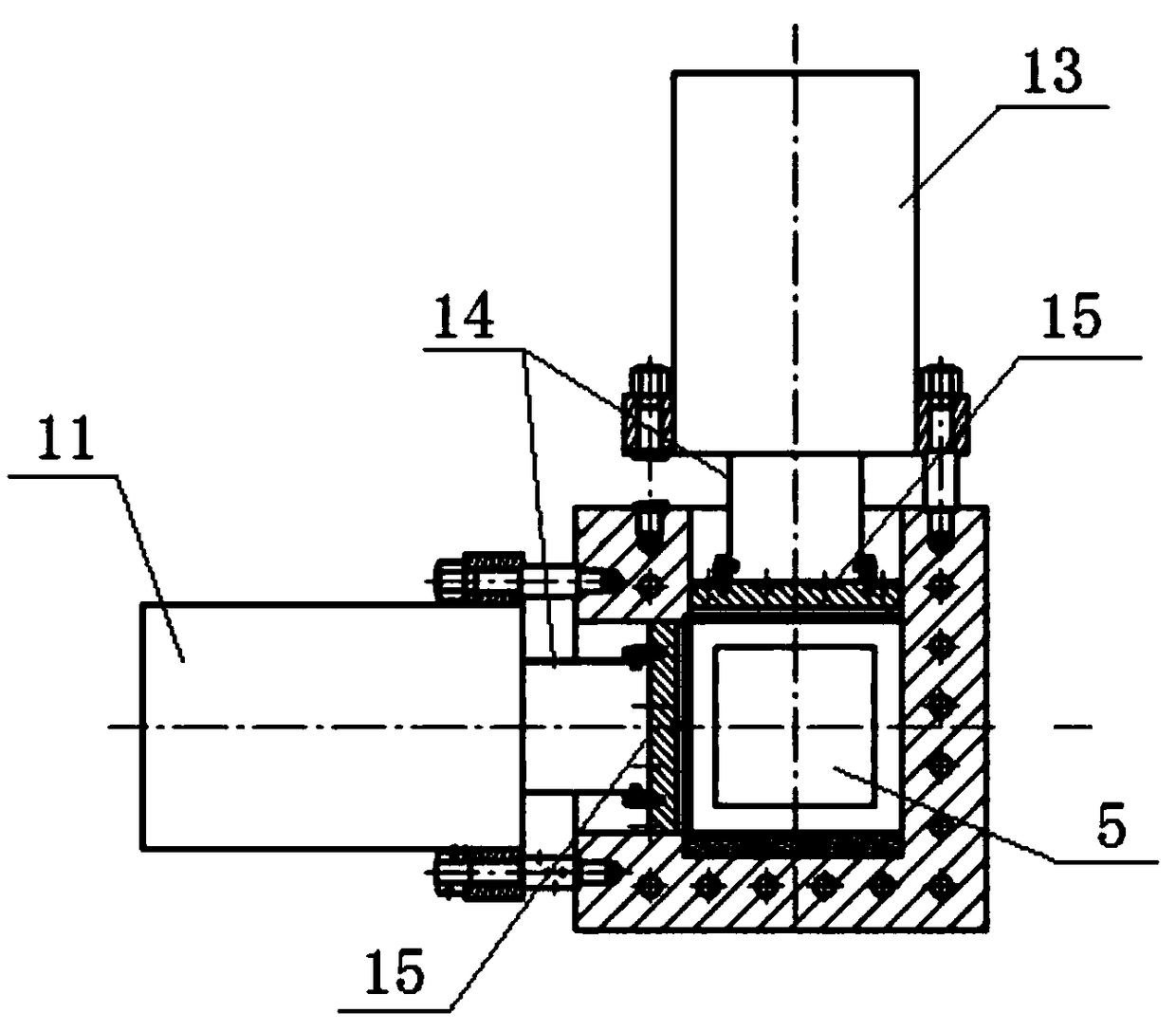

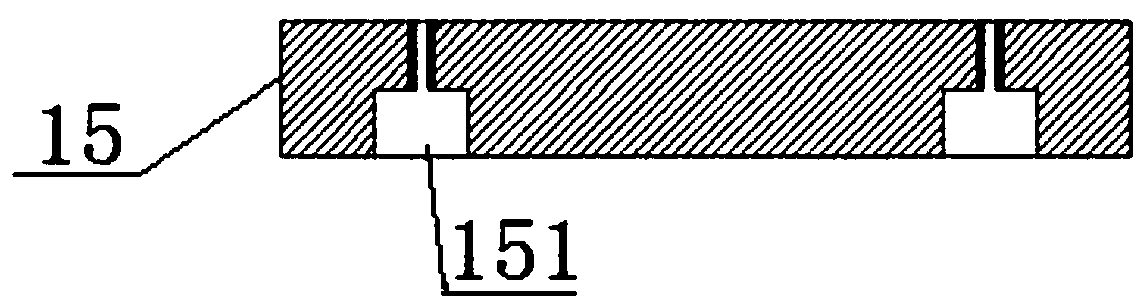

[0043] Embodiment 1, an experimental method integrating true triaxial fracture propagation simulation and permeability testing, which includes the following steps:

[0044] 1) Select natural or artificial rock, process the rock into a 40×40×40cm test piece, and then process and drill a central hole with a diameter of 2cm and a depth of 30cm at the center of one end of the test piece, and embed it in the central hole The fracturing tube is sealed with high-strength gel between the fracturing tube and the central hole, and then the test piece is sealed with a core sleeve, and the twelve sides and eight corners of the core sleeve and the test piece are pasted together with adhesive glue; The core sleeve is made of rubber resin material, the edge width is 35mm, the thickness is 1-3mm, and the eight corners adopt a conical structure, which plays the role of fully wrapping the eight corners of the test piece;

[0045] 2) Place the test piece in the pressure chamber of the true triax...

Embodiment 2

[0054] Embodiment 2, an experimental method integrating true triaxial fracture propagation simulation and permeability test, which includes the following steps:

[0055] 1) Select natural or artificial rock, process the rock into a 30×30×30cm test piece, then process and drill a central hole with a diameter of 2cm and a depth of 20cm at the center of one end of the test piece, and embed it in the center hole For the fracturing tube, prefabricate the sealing groove on the fracturing tube, and use the rubber ring to seal the gap between the fracturing tube and the central hole, and then use the core sleeve to seal the test piece, and use adhesive glue to connect the core set and the twelve pieces of the test piece. The sides and the eight corners are pasted together; the core sleeve is made of rubber resin material, the edge width is 25mm, the thickness is 1-3mm, and the eight corners adopt a conical structure, which plays the role of fully wrapping the eight corners of the test ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com