Intelligent staged hydraulic fracturing device for coal bed and method thereof

A technology for fracturing location and coal seam, applied in the field of coal seam fracturing, can solve the problems of low reliability, scrapped well, complicated operation process, etc., and achieves rapid cut-off and conduction, good fracturing effect, and good use effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

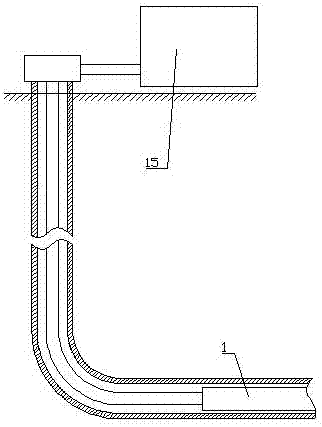

[0039] A coal seam intelligent staged fracturing device, such as figure 1 As shown, the fracturing fluid source 9 is included, and the fracturing fluid source 9 is used to provide fracturing fluid to realize fracturing of the coal seam. During implementation, the source of fracturing fluid includes a fracturing vehicle, and the supply of fracturing fluid is realized through the fracturing vehicle; or the source of fracturing fluid includes a pump body, and the pump body is connected to the source, so as to realize the supply of fracturing fluid with pressure. Both the split car and the pump body are mature existing technologies.

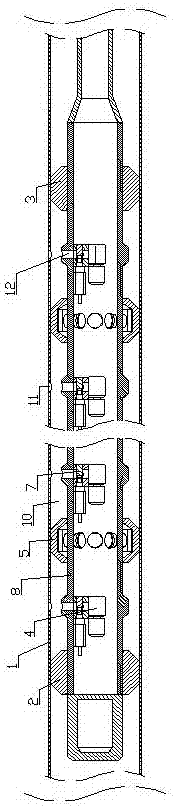

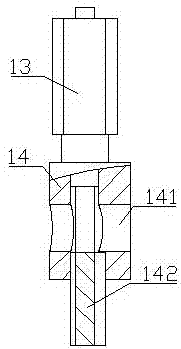

[0040] A casing 1 is connected to the fracturing fluid source 9, such as figure 2 As shown, the casing 1 is sleeved with a base pipe 8 , wherein the base pipe 8 communicates with a fracturing fluid source 9 , so that the fracturing fluid enters into the base pipe 8 through the fracturing fluid source 9 . In order to allow the fracturing fluid to c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com