Seal lip surface quality detection system based on array pressure sensor

A pressure sensor and surface quality technology, applied in the field of seal lip quality inspection, can solve the problems of high labor intensity, economic loss, time-consuming and laborious, etc., and achieve the effect of reducing labor intensity of workers, high measurement accuracy, and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

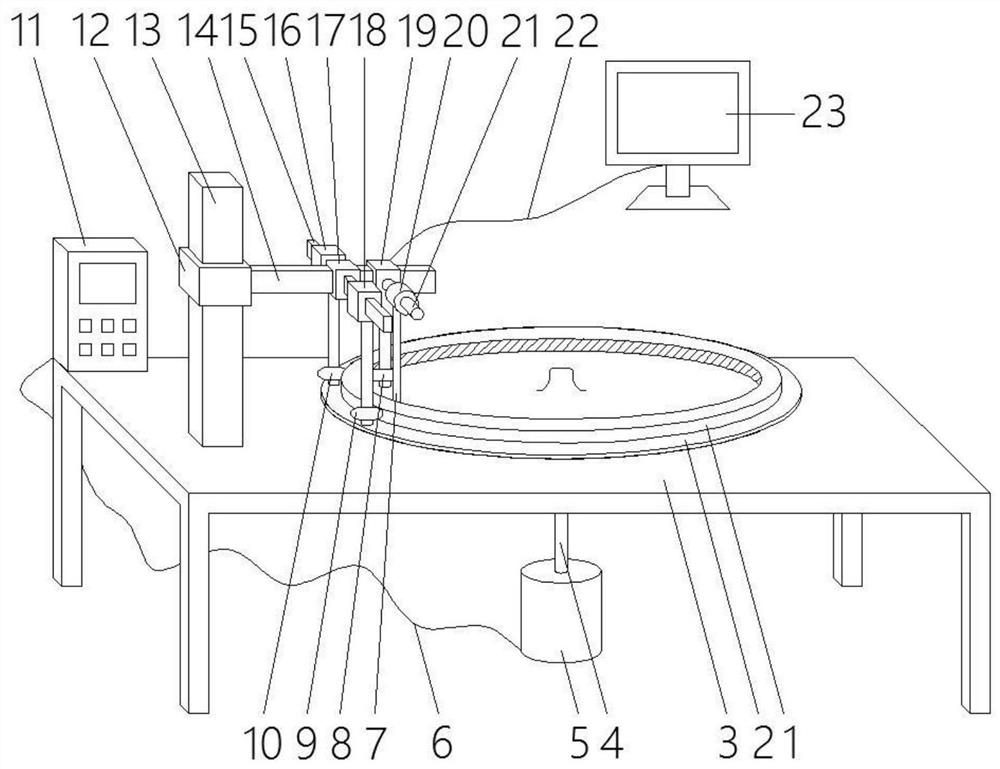

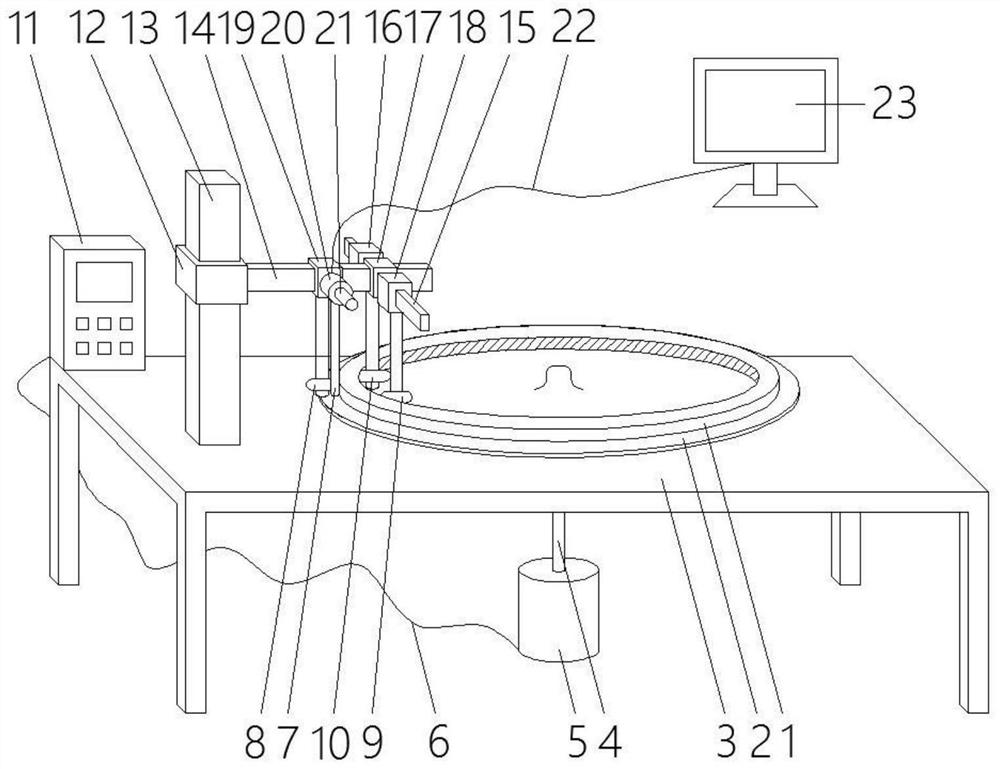

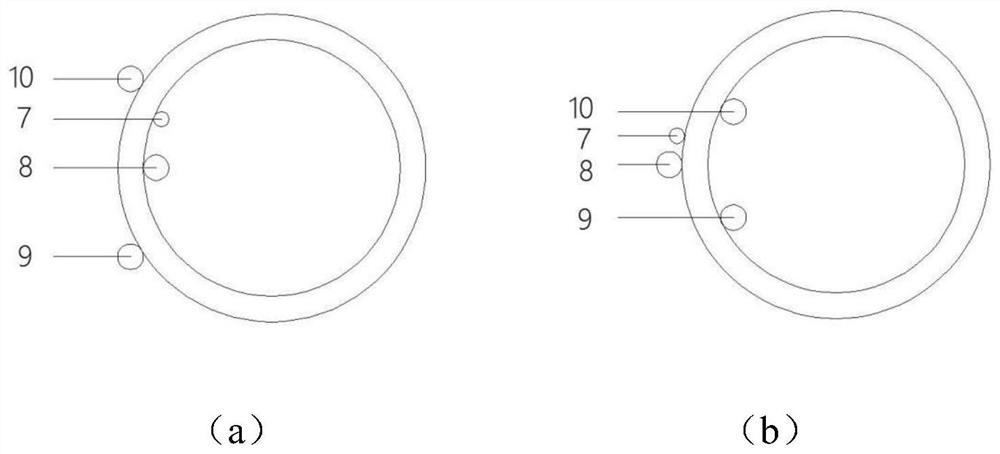

[0028] refer to figure 1 and figure 2 , a seal lip surface quality detection system based on an array pressure sensor, including a workbench 3, a motor 5 is arranged under the workbench 3, and the output shaft of the motor 5 is connected to the turntable 2 on the workbench 3 through a shaft 4; One side of the platform 3 table top is provided with a vertical slide rail 13, the vertical slide rail 13 is equipped with a vertical slide block 12, the vertical slide block 12 is connected with a horizontal slide rail 14, and the first party is set on the horizontal slide rail 14. Shaped slide block 17, the second square slide block 19;

[0029] Both sides of the first square slide block 17 are connected with the first horizontal support 15, the first horizontal support 15 is perpendicular to the horizontal slide rail 14, a third square slide block 16 is i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com