Surface quality detecting assembly line for electric automobile covering part

A technology of surface quality and electric vehicles, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of inability to realize assembly line operation and low efficiency, so as to save manual feeding and unloading, improve stability, and be good The effect of the clamping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

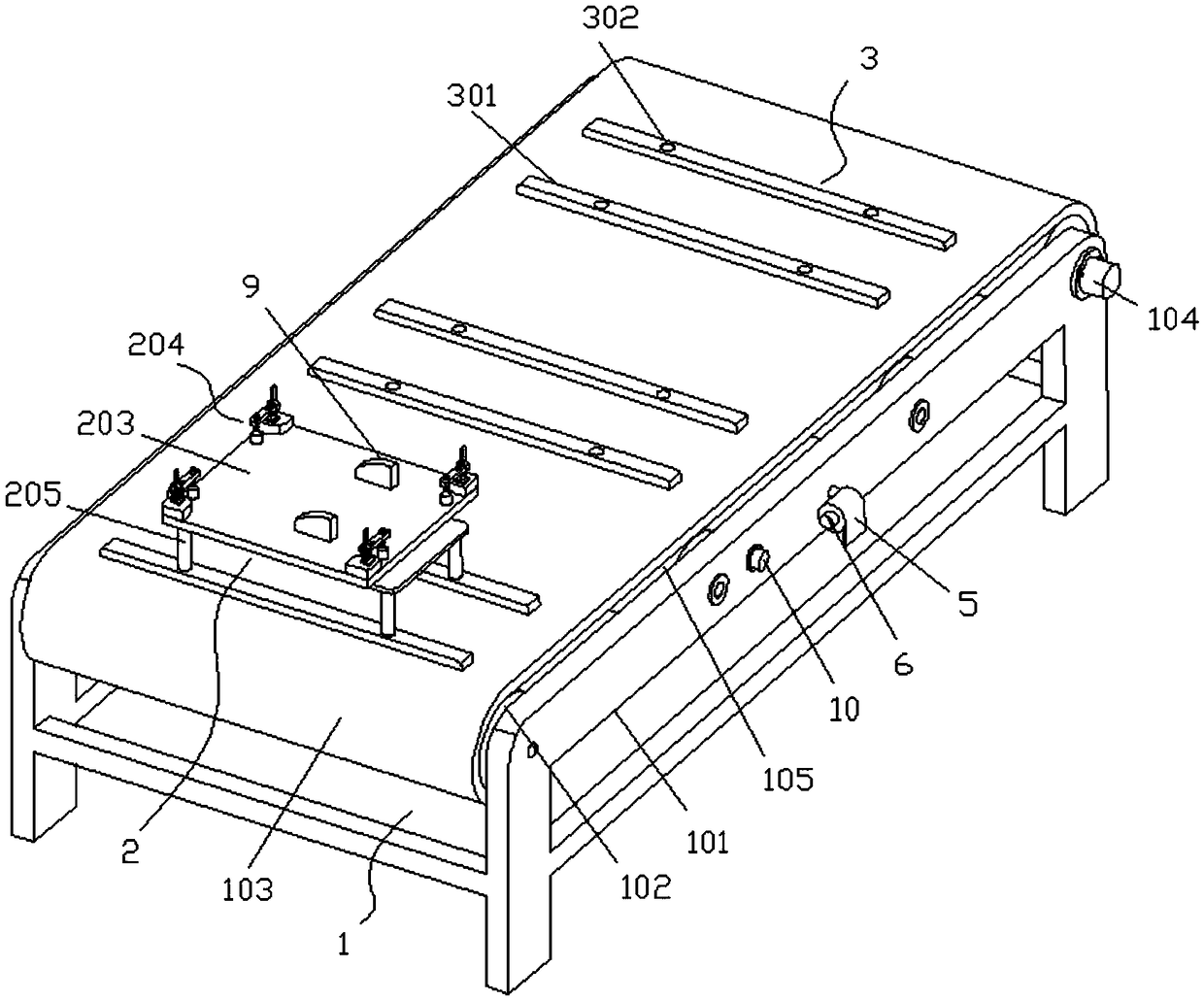

[0032] Such as Figure 1 to Figure 5 As shown, a surface quality detection assembly line for electric vehicle covers, including a conveying device 1, a detection component 2 and a positioning component 3;

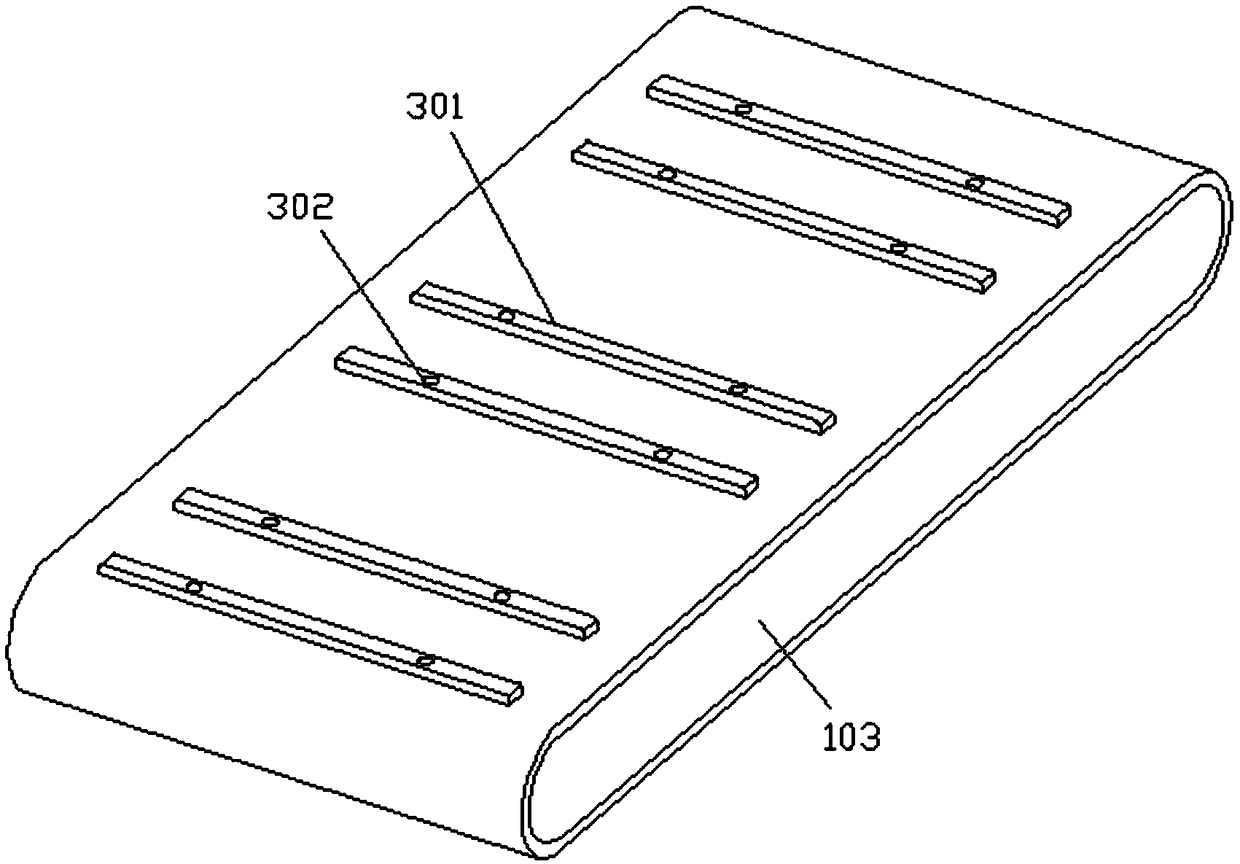

[0033] Described conveying device 1 comprises conveying frame 101, conveying roller 102, conveying belt 103 and conveying motor 104, conveying roller 102 is rotatably connected on conveying frame 101, and conveying motor 104 is installed on the outside of conveying frame 101 and with one of them The end of conveying roller 102 is connected to drive it to rotate, and several guide rollers 105 are also installed between conveying roller 102;

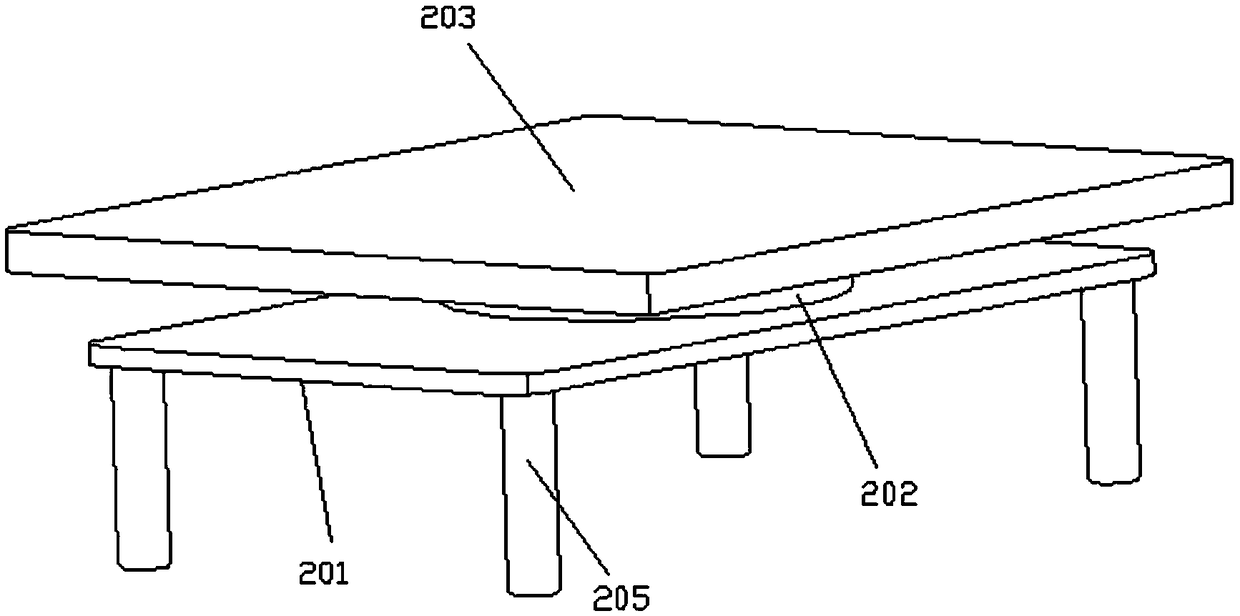

[0034] The detection assembly 2 includes a base 201, a slewing bearing 202, a detection bracket 203 and a clamping device 204. The bottom of the base 201 is provided with a positioning column 205, and the top of the base 201 is equipped with the slewing bearing 202. The detection bracket 203 is installed on the top of the slewing beari...

Embodiment 2

[0040] Such as Figure 1 to Figure 5 As shown, a surface quality detection assembly line for electric vehicle covers, including a conveying device 1, a detection component 2 and a positioning component 3;

[0041] Described conveying device 1 comprises conveying frame 101, conveying roller 102, conveying belt 103 and conveying motor 104, conveying roller 102 is rotatably connected on conveying frame 101, and conveying motor 104 is installed on the outside of conveying frame 101 and with one of them The end of conveying roller 102 is connected to drive it to rotate, and several guide rollers 105 are also installed between conveying roller 102;

[0042] The detection assembly 2 includes a base 201, a slewing bearing 202, a detection bracket 203 and a clamping device 204. The bottom of the base 201 is provided with a positioning column 205, and the top of the base 201 is equipped with the slewing bearing 202. The detection bracket 203 is installed on the top of the slewing beari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com