Split iron core stator double-layer winding structure and mounting method thereof

An iron core stator and double-layer winding technology, which is applied to the shape/style/structure of winding conductors, electromechanical devices, electric components, etc., can solve the problem of inability to ensure smooth entry of coils into slots, inability to achieve split stator splicing, and inability to proceed smoothly embedding and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

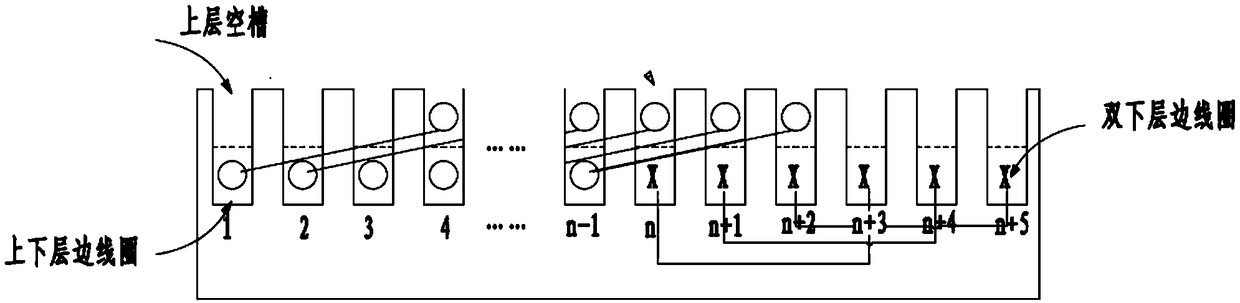

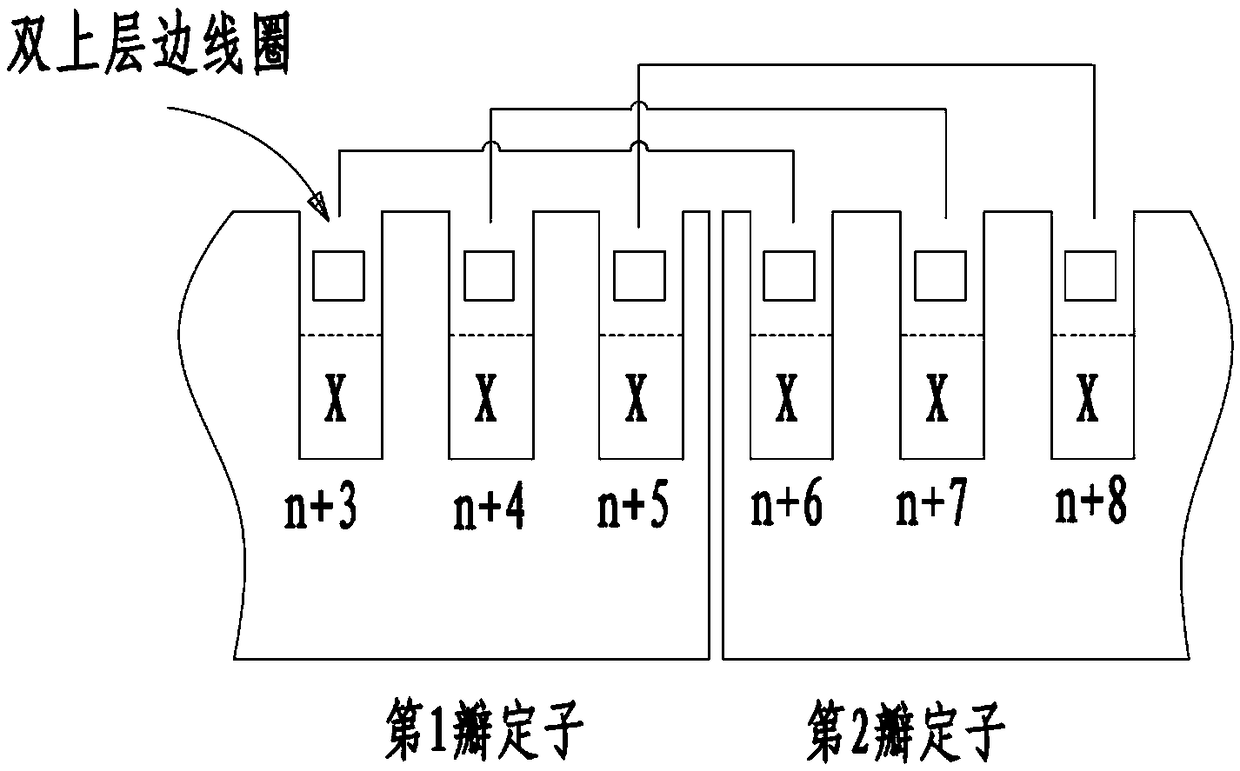

[0025] The invention discloses a double-layer winding structure of a split iron core stator, and the stator of the motor is in the axial direction. The stator is spliced by multiple split stators. Viewed from the axial direction of the motor, the stator is spliced by multiple (two or more) split stators in the circumferential direction. The splicing position can be located at the teeth of the iron core or at the groove of the iron core. Can be the same or different.

[0026] Each stator core includes a plurality of slots spaced apart along the circumference, and two coils are embedded in each slot. In said slot, the active sides of the two coils are stacked together. The upper half of the slot that defines the effective side of the coil without embedding is called the upper empty slot. At the splicing position of the one-lobe stator and the adjacent other-lobe stator, one-lobe stator has m-pitch upper empty slots, the other slots are embedded with coil effective sides, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com