Preparation sterilizing equipment for particle-containing liquid beverage and preparation method of particle-containing liquid beverage

A technology for sterilization equipment and liquids, applied in cleaning methods and utensils, chemical instruments and methods, mixers with rotary stirring devices, etc., can solve problems such as increasing production costs and time, unable to ensure complete sterilization of particles, and damage to particle products. , to achieve the effect of reducing configuration costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

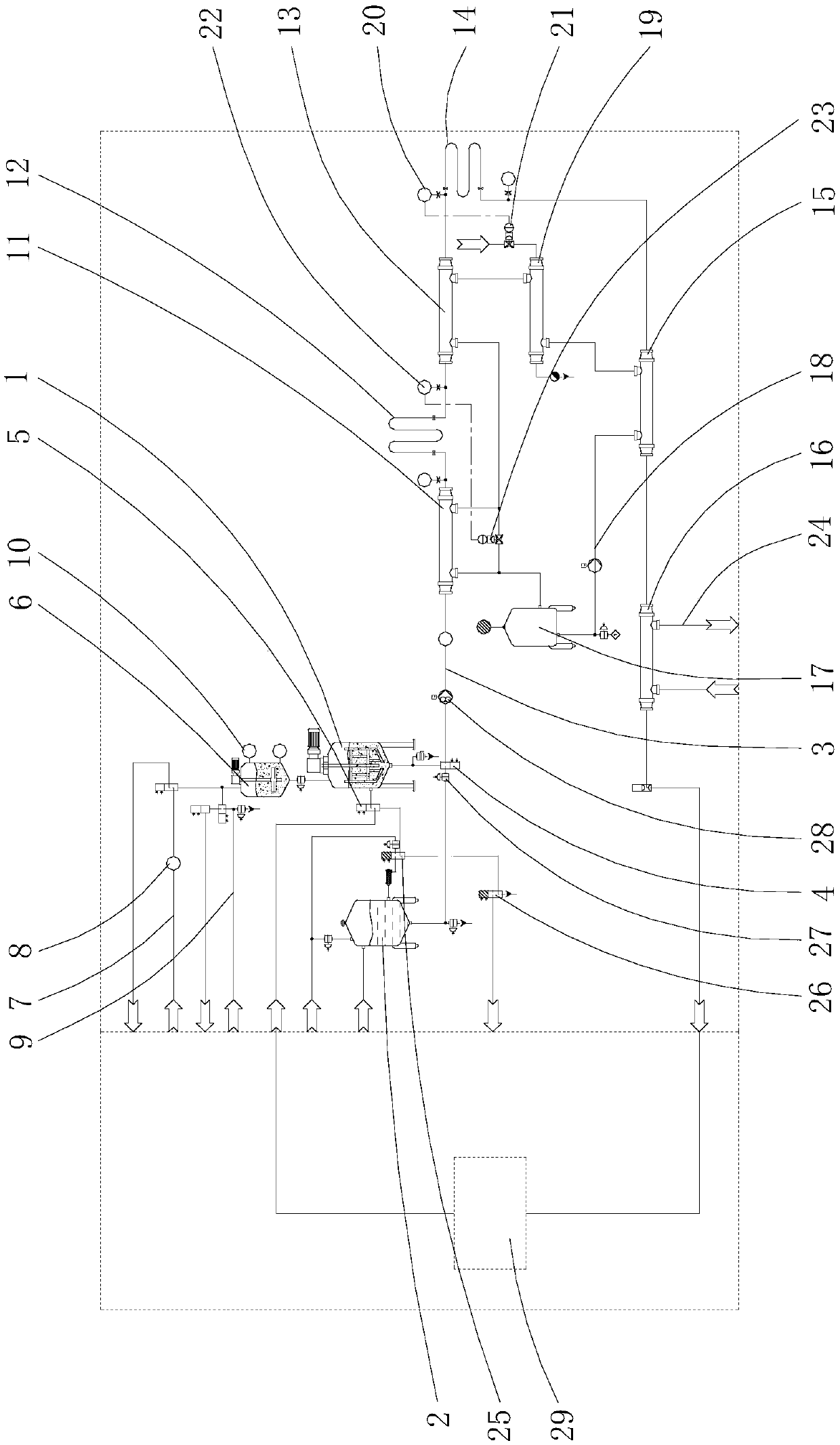

[0023] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

[0024] see figure 1 As shown, the above-mentioned sterilizing equipment for liquid beverage containing particles includes a storage container 1 and a batching mechanism communicated with the storage container 1 . The batching mechanism includes a batching container 6 communicated with the batching container 1, a liquid inlet pipeline 7 connected to the batching container 6, a flow meter 8 arranged on the liquid inlet pipeline 7, and a particle inlet pipe connected to the batching container 6. Road 9, the liquid level sensor 10 located in the batching container 6; the liquid level sensor 10 is used to judge whether the particles entering the batching container 6 will raise the liquid level in the batching container 6 to a set height.

[0025] In this embodiment, the liquid level when the liquid medium reaches 100L is defined as the set liquid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com