Shock-proof connecting pipe of dish washing machine

A technology for connecting pipes and dishwashers, applied in the direction of pipes/pipe joints/fittings, tableware washing machines/rinsing machines, hoses, etc., to avoid clogging and water leakage accidents and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in combination with specific embodiments.

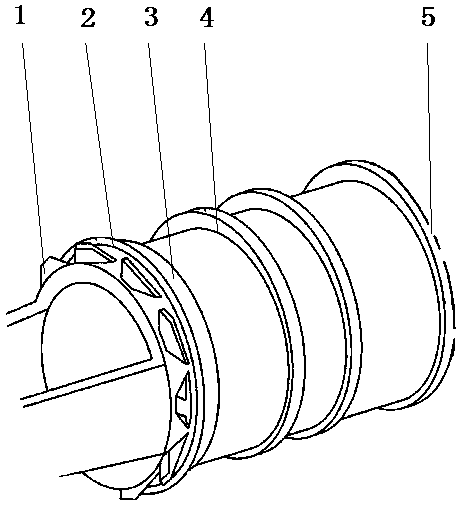

[0018] Such as figure 1 As shown, a dishwasher anti-vibration connecting pipe, the pressure dividing clip 1, the shock absorbing layer 2, the shrinking ring layer 3, the fixed ring layer 4 and the locking ring layer 5, the connecting pipe is a long strip structure, the connecting pipe The surface of the joint is provided with a pressure dividing clamp 1, which is a built-in irregular groove. The pressure dividing clamp 1 is evenly distributed on the connecting pipe, and one side of the pressure dividing clamp 1 is a water pipe. Connecting components, the other side of the pressure dividing card 1 is the shock absorbing layer 2, the shock absorbing layer 2 is an elastic ring structure, the shrinking ring layer 3 is under the shock absorbing layer 2, and the shrinking ring layer 3 is an inverted circular frustum ring structure, The diameter of the outer ring of the shrink ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com