Flexible clamping tool applicable to metal plate supports

A sheet metal bracket and clip flexibility technology, applied in metal processing equipment, metal processing mechanical parts, clamping and other directions, can solve the problems of high labor intensity, poor consistency, poor accuracy, etc., to achieve fast response speed and ensure the quality of hole making , the effect of strong adaptability

Active Publication Date: 2018-10-19

CAPITAL AEROSPACE MACHINERY +1

View PDF8 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] This method has the following shortcomings: poor precision, high labor intensity, and poor consistency

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

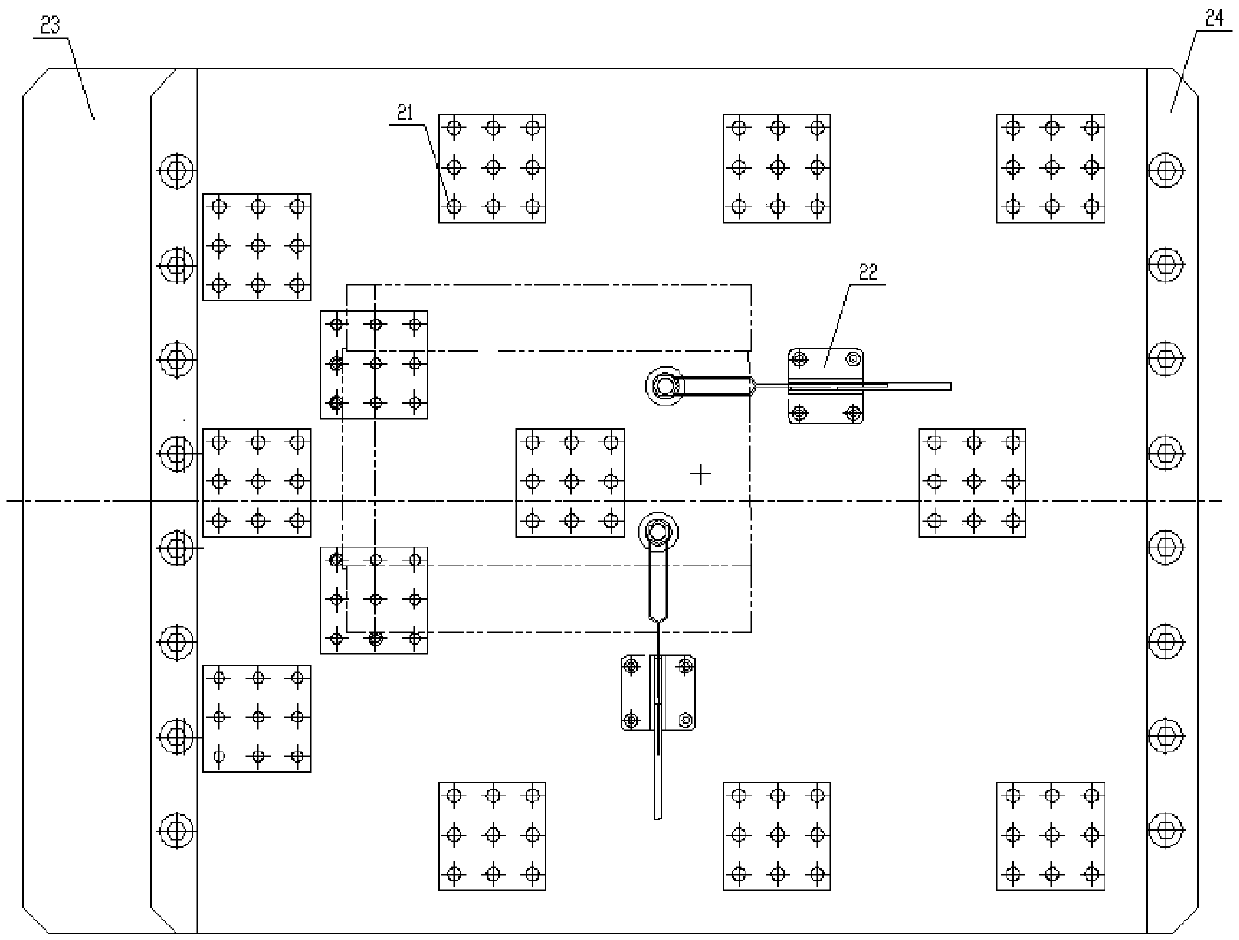

[0049] The overall dimensions (length×width×height) of a certain type of sheet metal bracket are 117×66×15, and the wedge angle is 3.5°. It is necessary to make 4-Ф5 on the bracket. After the tooling is quickly fixed and clamped to the sheet metal bracket, the machine tool spindle is used to make a hole with a standard drill bit, and the measurement results of the hole are Ф5.009, Ф5.006, Ф5.011, Ф5.010, and the accuracy can reach 7H.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

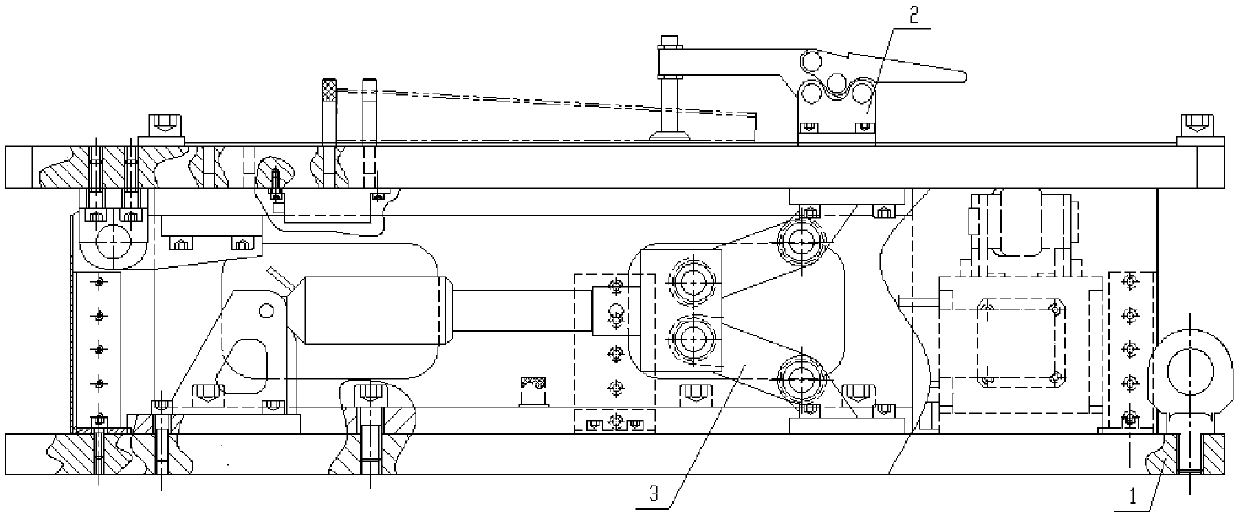

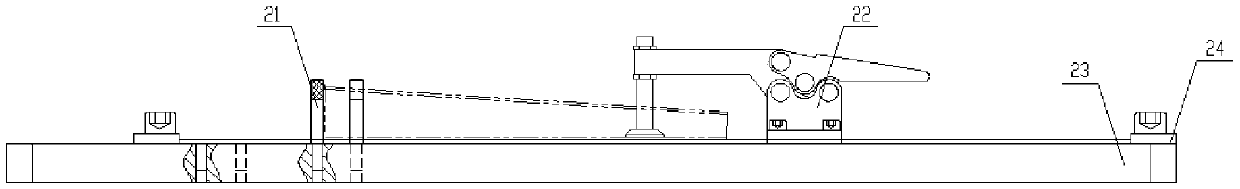

The invention relates to a flexible clamping tool applicable to metal plate supports, in particular to a structure form and a technology for pressing, locating and angle adjusting of thin-wall components with different wedge angles, and belongs to the technical field of clamping and locating. The flexible clamping tool applicable to the metal plate supports is applicable to fast locating and clamping of thin-wall component products of multiple specifications. The tool aims at the situations that the metal plate supports of various sizes and with different shapes exist on metal shells of guidedmissile weapons at the present stage, the specification and the number of metal plate parts with holes needing to be made are many correspondingly, these metal plate supports are in a wedge structure, and the wedge angles are different and range from 0 to 5 degrees. When the tool is used for carrying out hole making on the metal plate supports, the situations that corresponding locating and clamping tools are designed and manufactured for the different product shapes and the hole making requirements, waste of the tools is caused can be avoided. The tool can achieve fast locating and fast clamping for metal plates with the different shape sizes and wedge angles.

Description

technical field [0001] The invention relates to a clamping flexible tooling suitable for sheet metal brackets. The flexible tooling is suitable for fast positioning and clamping of multi-standard thin-walled parts and components, and specifically relates to the pressing and positioning of thin-walled parts with different wedge angles. 1. The structural form and technology of angle adjustment belong to the technical field of clamping and positioning. Background technique [0002] In view of the fact that there are sheet metal brackets of various sizes and shapes on the metal shell of missile weapons at this stage, the specifications and quantity of sheet metal parts that need to be made are correspondingly large. These sheet metal brackets are all wedge-shaped structures, and the wedge angles are different. There are differences, ranging from 0 to 5°. [0003] In the prior art, in the process of punching holes for sheet metal brackets, the holes are generally marked and punc...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B23Q3/06

CPCB23Q3/062B23Q3/066

Inventor 王洪福王志峰齐刚王学刚周世杰王贺敖洪峰许可人刘海燕易帆胡改娟许猛何凡锋翟大勇李世鹏毕煌圣牛犇王腾梁丹

Owner CAPITAL AEROSPACE MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com