Polishing device for environmental-friendly type automobile parts

A kind of spare parts and environment-friendly technology, applied in the direction of grinding drive device, grinding machine, grinding frame, etc., can solve the problems of environmental protection and protection, brake disc fixing and grinding, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

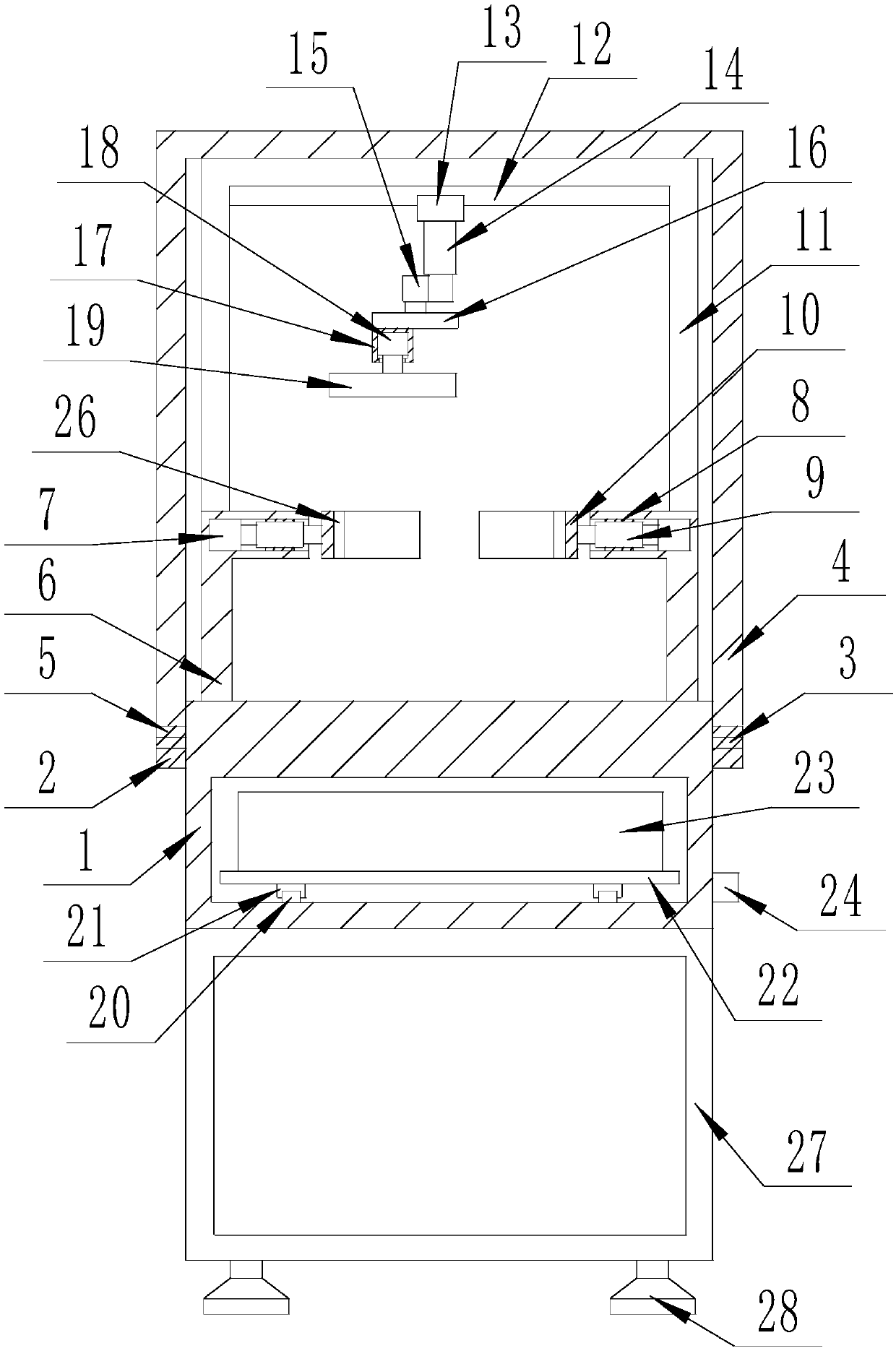

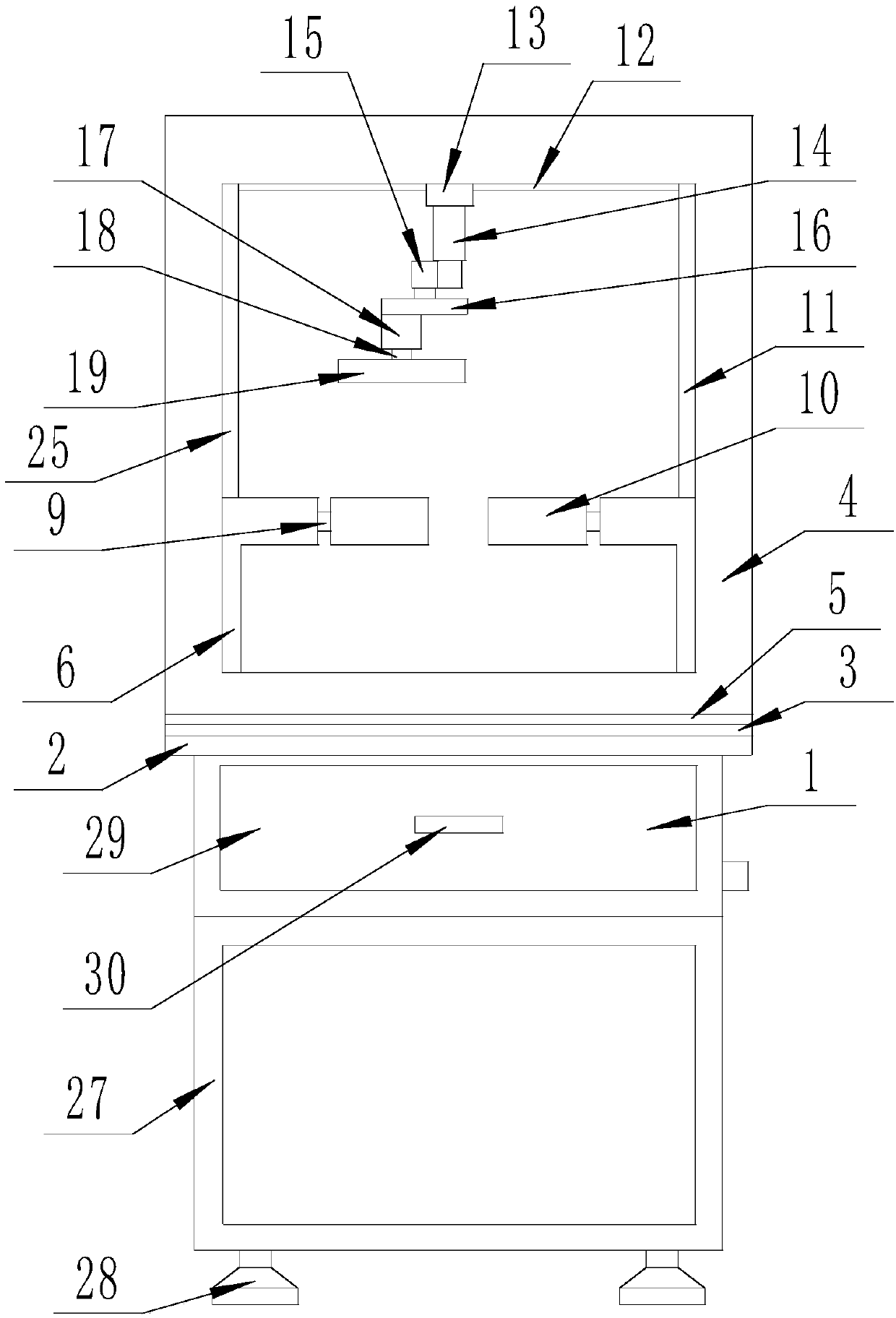

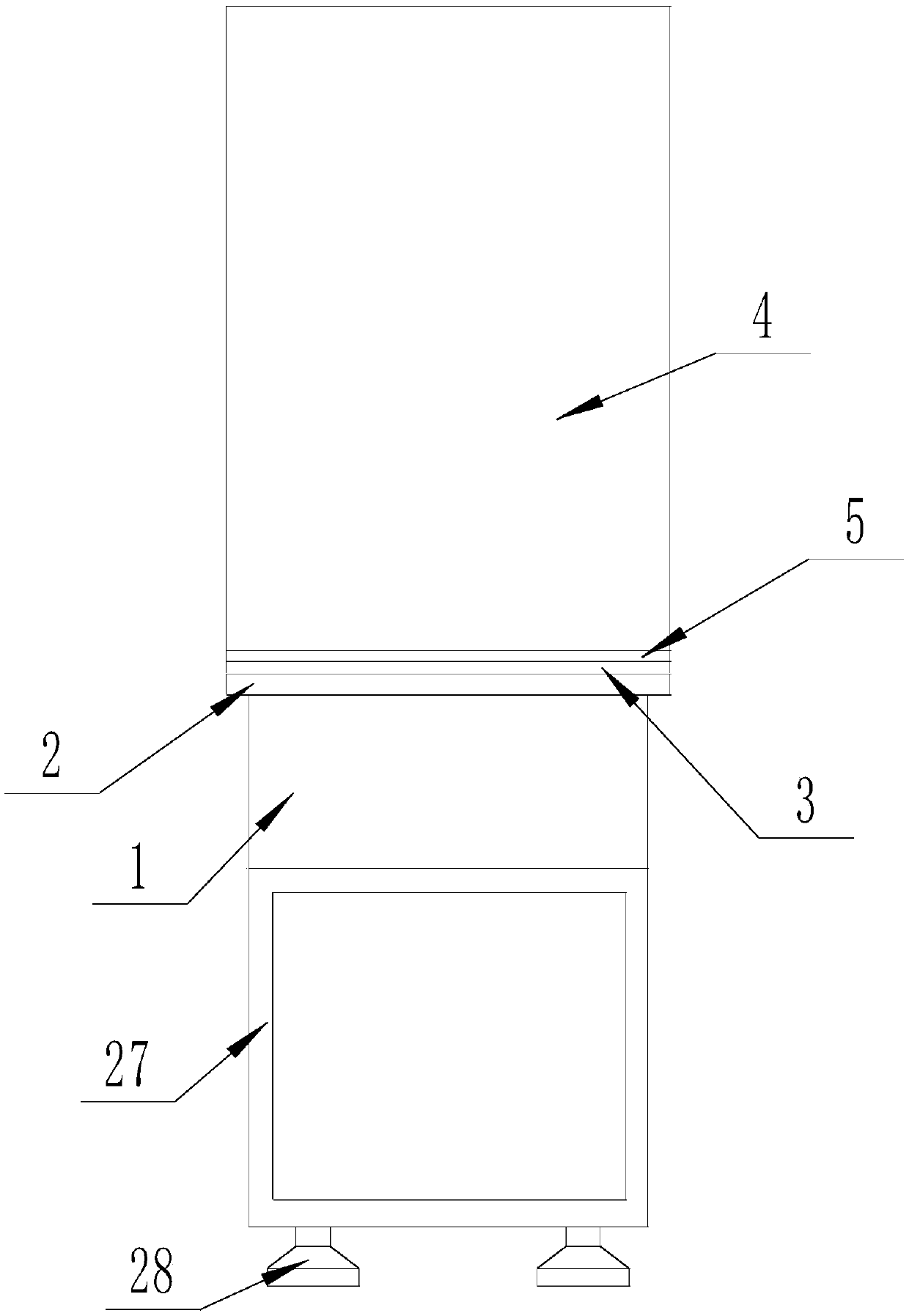

[0015] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-3 As shown, a kind of environment-friendly grinding device for auto parts includes a workbench 1, the outer surface of the workbench 1 is provided with an annular limiting plate 2, and the upper surface of the annular limiting plate 2 is provided with a No. 1 magnet 3. A protective casing 4 is provided above the annular limiting plate 2, and a No. 2 magnet 5 is provided on the lower surface of the protective casing 4. The No. 1 magnet 3 and the No. 2 magnet 5 are magnetically attracted. Both sides are provided with L-shaped struts 6, and each of the L-shaped struts 6 is processed with a circular groove on the opposite surface, and each of the circular grooves is equipped with a No. 1 rotating motor with the opposite rotating end 7. Each of the circular grooves is provided with a rotating cylinder 8, and each of the rotating ends of the No. 1 rotating motor 7 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com