Through-type bearing assemblies and tire automatic inflation powering-on system

A through-type, bearing technology, applied in tire measurement, tire parts, wheels, etc., can solve the problems of no good wheel side ventilation structure and ventilation route, no power supply for Bluetooth tire pressure detection module, no real-time feedback signal, etc., to achieve It is convenient, fast and safe to inflate, reducing the probability of accidents and reducing the effect of accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below, the substantive features and advantages of the present invention will be further described in conjunction with examples, but the present invention is not limited to the listed examples.

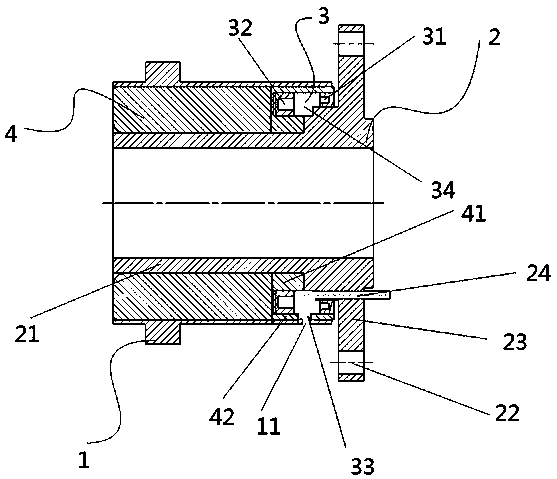

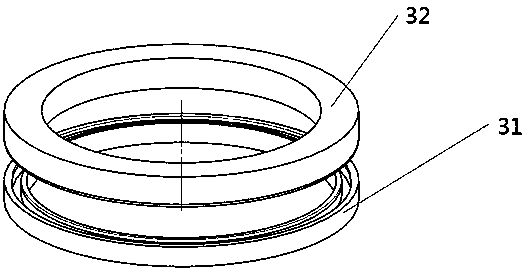

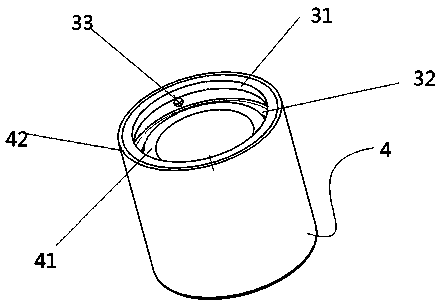

[0028] see Figure 1-9 As shown, the figure shows the structure of a through-type bearing assembly and tire automatic inflation and electrification system described in the embodiment of the present invention. For the convenience of description, only the relevant parts of the embodiment of the present invention are shown.

[0029] A through-type bearing assembly, including a bearing device and a shaft head 2, the bearing device includes a bearing 4 and a bearing seat 1, the shaft head 2 is tightly fitted in the bearing 4, and the bearing 4 is closely fitted In the bearing seat 1, the bearing seat 4 is provided with an air vent, the shaft head seat 1 is a horn shaft bearing, and the shaft head 2 includes a shaft head sleeve 21, a shaft head plate 23, a shaft head tire screw hole 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com