Bicycle transmission device

A transmission device and bicycle technology, applied to chain/belt transmission devices, vehicle parts, vehicle gearboxes, etc., can solve the problems of increasing manufacturing difficulty, manufacturing cost, and complex structure, so as to reduce manufacturing cost and manufacturing difficulty, and simplify the structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

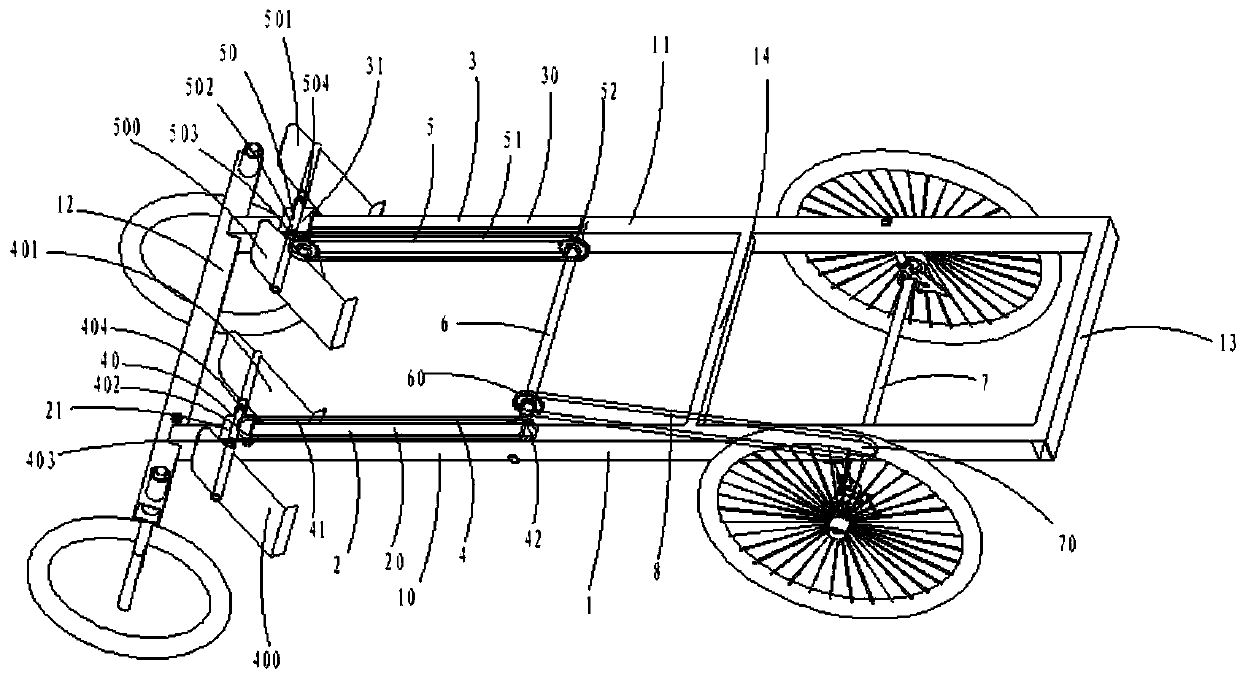

[0021] ginseng figure 1 As shown, a bicycle transmission device includes: a vehicle frame 1 and a first guide mechanism 2 arranged on the vehicle frame 1, a second guide mechanism 3, a first linear pedal mechanism 4, a second linear pedal mechanism 5, a middle Transmission shaft 6 and rear wheel transmission shaft 7.

[0022] The vehicle frame 1 includes a first longitudinal beam 10, a second longitudinal beam 11, a first beam 12 arranged at one end of the first longitudinal beam 10 and the second longitudinal beam 11, a first crossbeam 12 arranged at one end of the first longitudinal beam 10 and the second longitudinal beam 11, the second beam 13 at the other end and the intermediate beam 14 arranged between the first longitudinal beam 10 and the second longitudinal beam 11, the first guide mechanism 2 is arranged on the first longitudinal beam 10, and the second guide The mechanism 3 is arranged on the second longitudinal beam 11 .

[0023] The first guide mechanism 2 incl...

Embodiment 2

[0031] In Embodiment 1, the first transmission belt 41 and the second transmission belt 51 drive the rear wheel transmission shaft 7 through the transmission of the intermediate transmission shaft 6, but in this embodiment, no intermediate transmission shaft is provided, and they are directly on the rear wheel transmission shaft 7. A first transmission wheel matched with the first transmission belt 41 and a second transmission wheel matched with the second transmission belt 51 are provided, and the rear wheel transmission shaft 7 is directly driven by the first transmission belt 41 and the second transmission belt 51 .

[0032] To sum up, the bicycle transmission device in the present invention reduces the four sets of linear pedaling mechanisms in the prior art to two sets of linear pedaling mechanisms, and correspondingly improves the structure of the pedaling parts that match the two sets of linear pedaling mechanisms. Therefore, the structure is greatly simplified, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com