A kind of ultra-thin chemically strengthened glass and preparation method thereof

A glass strengthening and chemical technology, applied in the field of ultra-thin chemical strengthening glass and its preparation, can solve the problems of long time consumption of chemical strengthening, low ion mobility, environmental pollution, etc., to achieve improved chemical strengthening effect, good light transmittance, Effect of improving ion exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0028] In order to better illustrate the purpose, technical solutions and advantages of the present invention, the present invention will be further described below in conjunction with specific examples. Those skilled in the art should understand that the specific embodiments described here are only used to explain the present invention, and are not intended to limit the present invention.

[0029] In the examples, the experimental methods used are conventional methods unless otherwise specified, and the materials and reagents used are commercially available unless otherwise specified.

[0030] The thickness of the glass sample prepared in the present invention is below 1.5mm.

Embodiment 1

[0032] The preparation method of the ultra-thin chemically strengthened glass described in this embodiment comprises the following steps:

[0033] (1) prepare ion exchange solution;

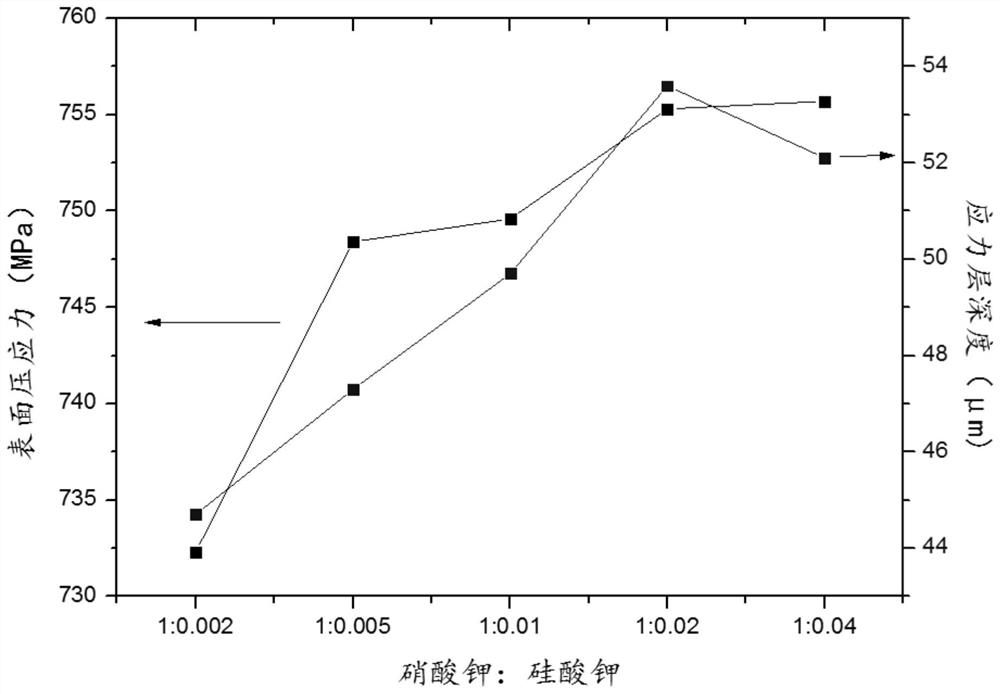

[0034] Potassium nitrate, potassium silicate, rubidium nitrate and cesium nitrate are dissolved in ultrapure water to obtain an ion exchange solution, in which K + The concentration is 30mol / L, Rb + The concentration is 2.5mol / L, Cs + The concentration is 3.0mol / L, and the molar ratio of potassium nitrate and potassium silicate is set as 1:0.002, 1:0.005, 1:0.01, 1:0.02 and 1:0.04;

[0035] (2) After cutting and polishing the glass, use acetone and ethanol to clean the glass surface and dry it;

[0036] (3) Soak the dried glass in the ion exchange solution, and place it in a microwave hydrothermal instrument for ion exchange treatment; the microwave hydrothermal temperature is 340° C., and the ion exchange time is 5 hours;

[0037] (4) After the ion exchange is completed, cool to room tempera...

Embodiment 2

[0042] The preparation method of the ultra-thin chemically strengthened glass described in this embodiment comprises the following steps:

[0043] (1) prepare ion exchange solution;

[0044] Potassium nitrate, potassium silicate, rubidium nitrate and cesium nitrate are dissolved in ultrapure water to obtain an ion exchange solution, in which K + The concentration is 36mol / L, Rb + The concentration is 3mol / L, Cs + The concentration is 2.0mol / L, and the molar ratio of potassium nitrate to potassium silicate is 1:0.02;

[0045] (2) After cutting and polishing the glass, use acetone and ethanol to clean the glass surface and dry it;

[0046] (3) Soak the dried glass in the ion exchange solution, and place it in a microwave hydrothermal instrument for ion exchange treatment; the microwave hydrothermal temperature is 320° C., and the ion exchange time is 8 hours;

[0047] (4) After the ion exchange is completed, cool to room temperature, take out the glass sample, ultrasonically...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com