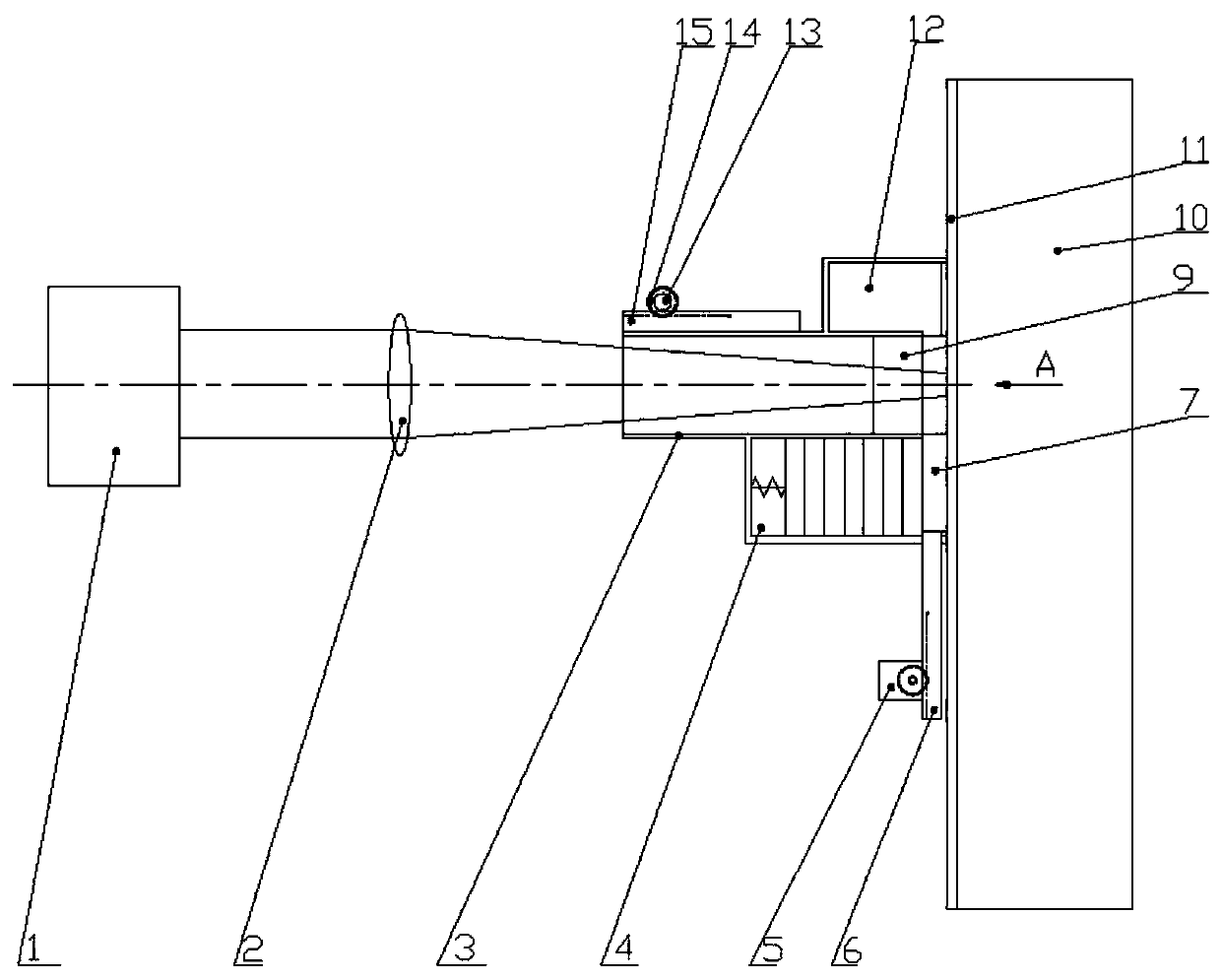

A laser shock device that can automatically replace the glass constrained layer

An automatic replacement and laser shock technology, which is applied in the field of laser shock strengthening, can solve problems such as the trouble of replacing the constrained layer, achieve the effects of improving strength and duration, reducing the difficulty of replacement, and reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

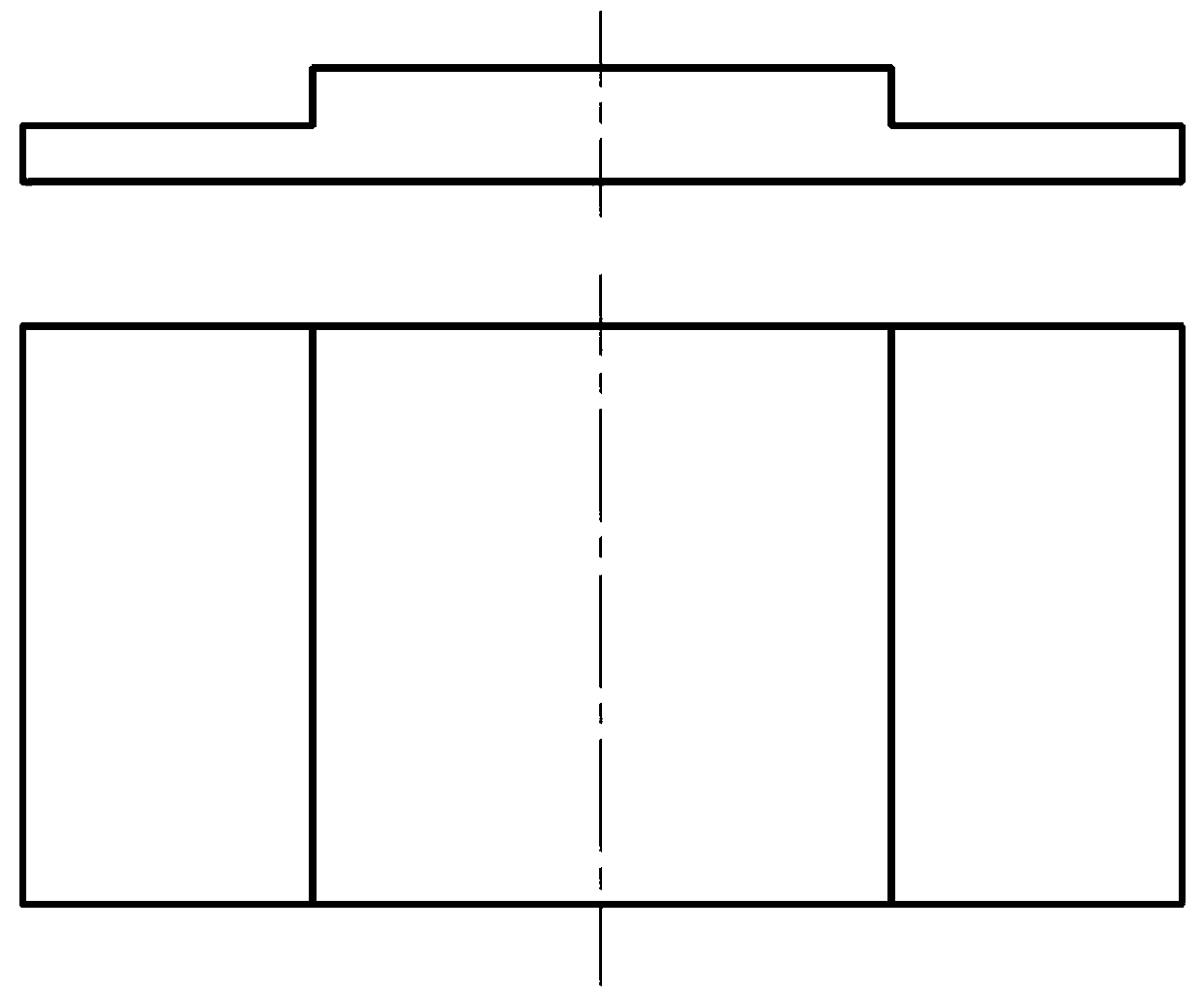

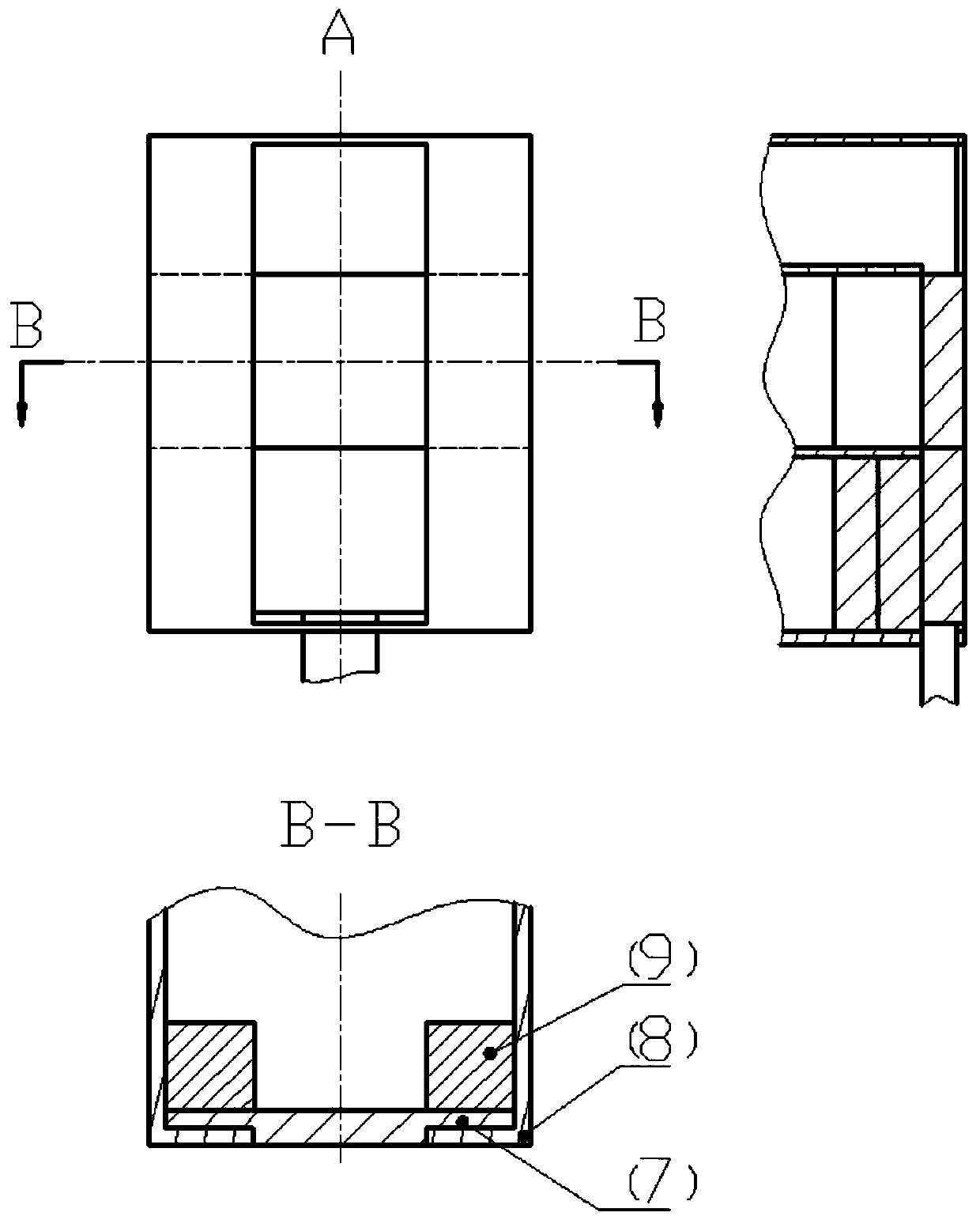

[0026] The specific implementation method is as follows: the computer input signal to the stepper motor 5, the stepper motor 5 drives the replacement rack 6 and pushes the first dedicated constraint layer 7 along the chute of the glass sheet baffle plate 8 to the rubber buffer pad 9 and the glass sheet Between the baffles 8, the replacement rack 6 returns to its original position, and at the same time the spring pushes the next dedicated constraining layer 7 above the replacement rack 6, and the fine-tuning knob 13 is adjusted so that the special constraining layer 7 is tightly pressed against the surface of the absorbing layer 11 The laser 1 emits a pulsed laser, and the laser beam radiates to the surface of the absorbing layer 11 through the focusing lens 2 and the special confinement layer 7, and completes a laser shock. After the shock process is carried out several times, it enters the constraining layer replacement procedure; After the last laser shock is over, the comput...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com