Control method for inlet area steel heaping on continuous hot dip galvanization production line

A technology of entrance area and control method, which is applied in hot-dip plating process, coating, metal material coating process, etc., can solve problems such as steel stacking in the entrance area, prevent steel accumulation in the entrance area, and solve the problem of steel accumulation in the entrance area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The embodiment of the present invention provides a method for controlling stacking of steel in the entrance area of a continuous hot-dip galvanizing production line, which at least partially solves the technical problem of steel stacking in the entrance area of the hot-dip galvanizing line in the prior art.

[0027] In order to solve the technical problems in the above-mentioned prior art, the general idea of the technical solution provided by the embodiment of the present application is as follows:

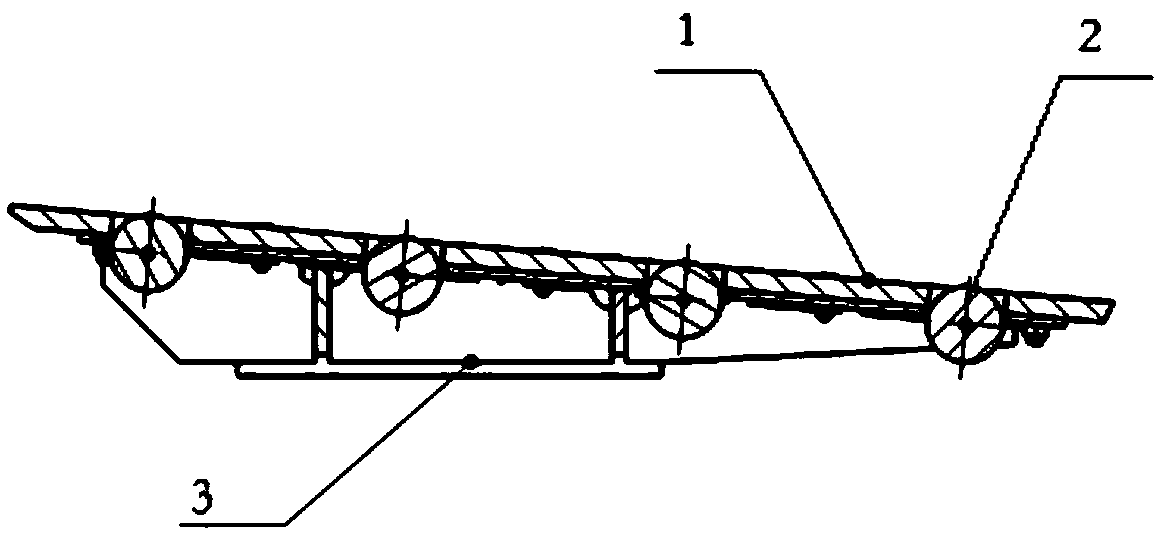

[0028] Rolling bearings are set on the guide plate for threading the raw material coils, and the linkage between the positioning grating at the entrance of the hot-dip galvanizing production line and the uncoiler is set.

[0029] In the above method, by arranging a rolling bearing on the guide plate used for threading the raw material coil, the bonding between the strip steel and the guide plate can be avoided, thereby preventing the stacking of steel in the entrance ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com