Hot-rolled double-layer bimetal composite plate splitting and turning machine

A technology of bimetal and plate turning machine, which is applied in the direction of metal rolling, metal rolling, metal processing equipment, etc., can solve the problems that the known equipment cannot meet the continuous production, cannot meet the requirements of extended processing, and affects product quality, etc., and achieves Improve the quality of product coiling, avoid stacking steel, and avoid the effect of interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

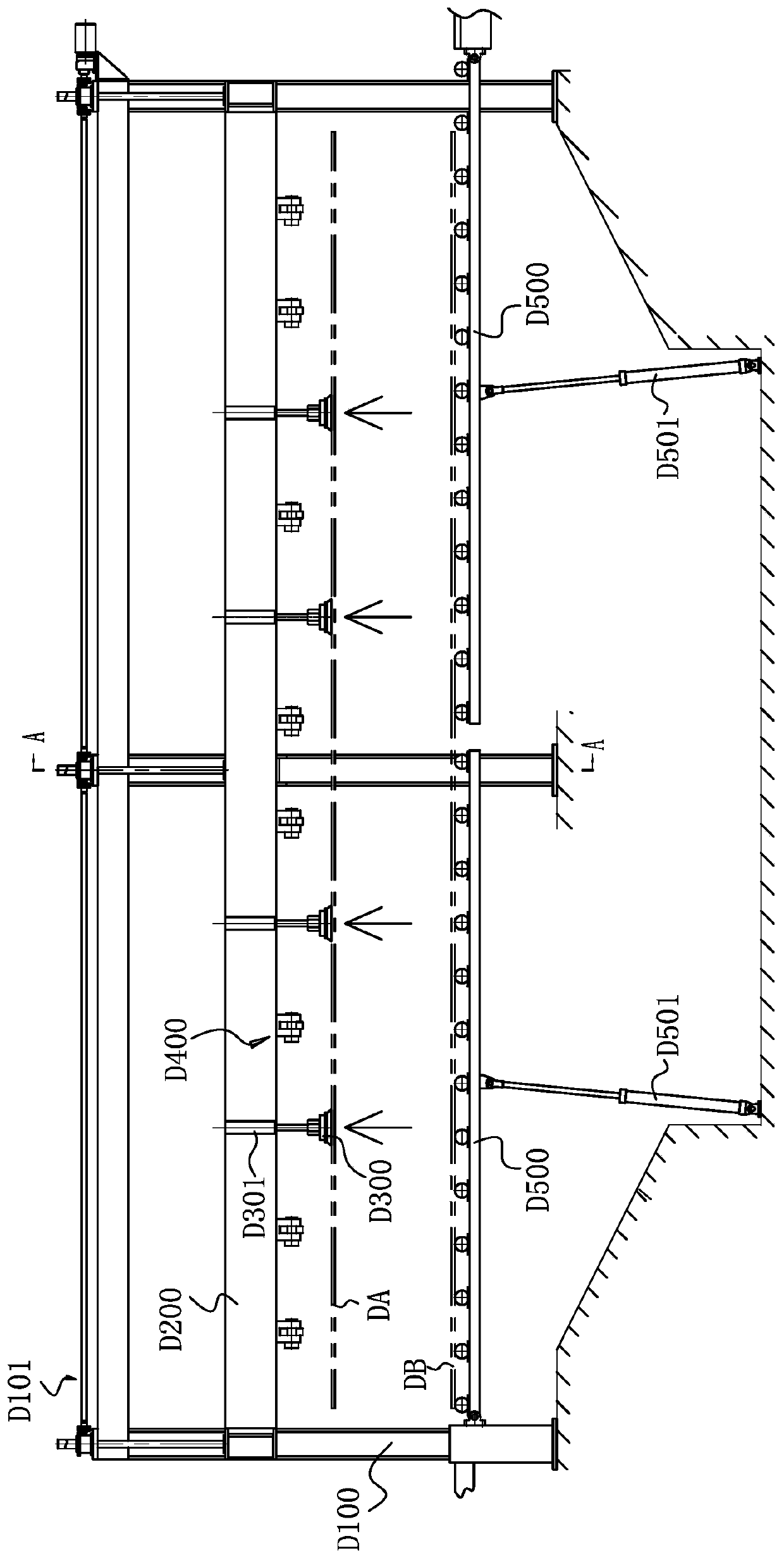

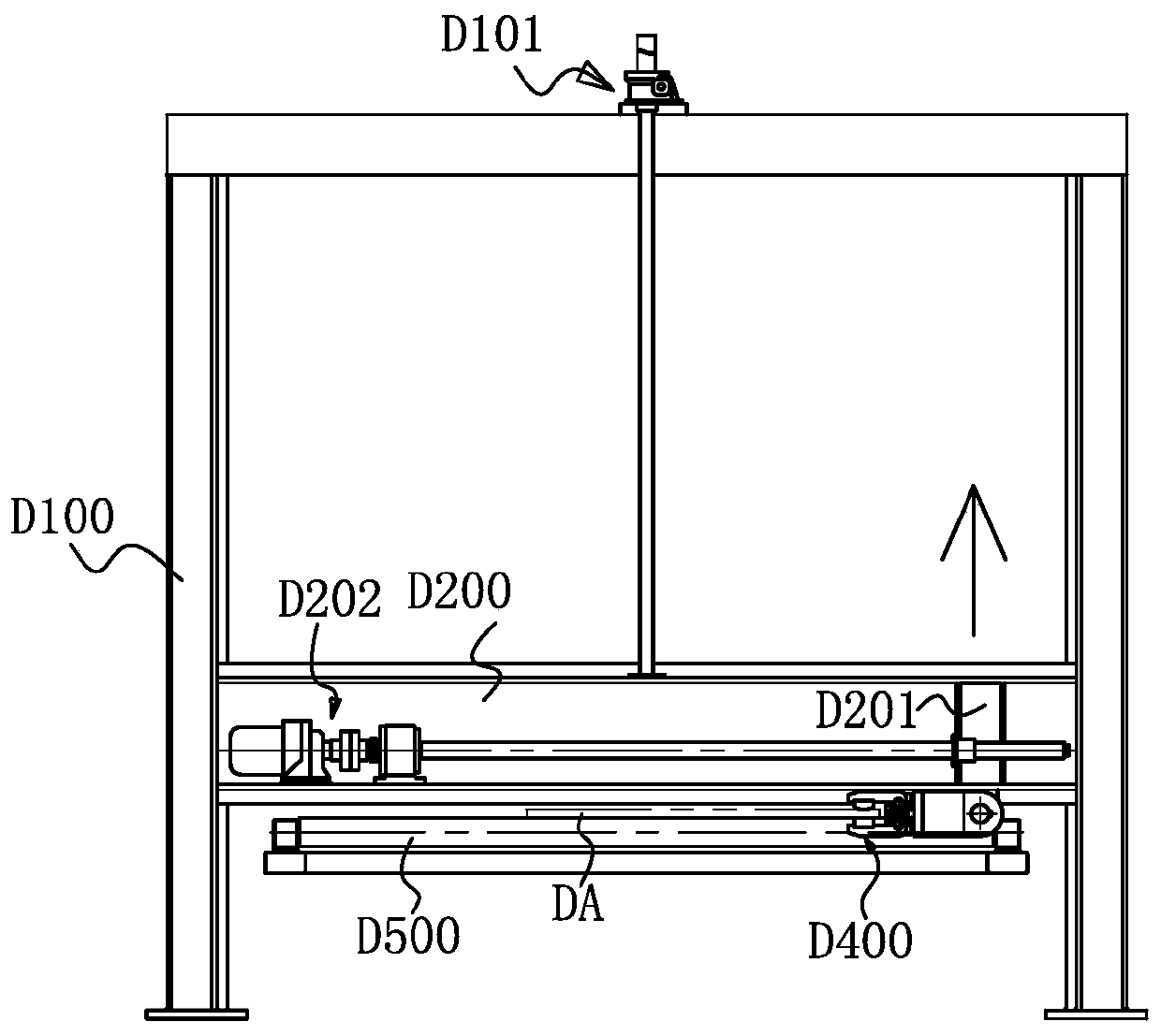

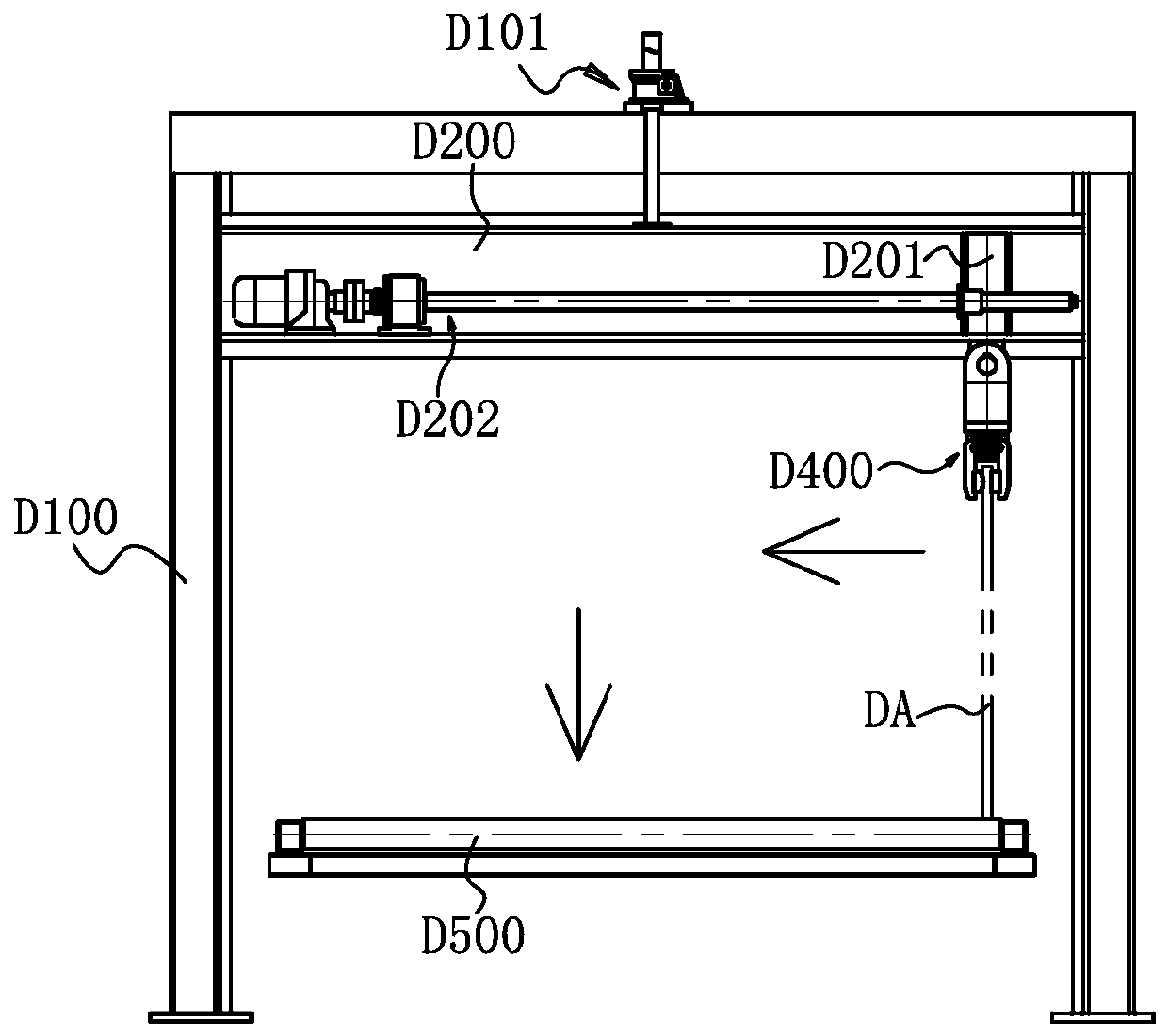

[0026] Such as figure 1 As shown, a hot-rolled double-layer bimetallic composite plate splitting and turning machine is provided with a conveying roller table D500 under the gantry frame D100. When only conveying hot-rolled double-layer bimetal composite plates, the conveying roller table D500 can be set as a fixed type. When taking into account the conveying of hot-rolled double-layer bimetal composite plates or coils, the conveying roller table D500 is set as a swing bridge type, figure 1 Among them, there are two conveying roller tables D500, which are respectively driven by the swing bridge oil cylinder D501, and the swing joints of the two conveying roller tables D500 are respectively located at both ends of the gantry frame D100. A pit is formed in the foundation to store the amount of loops formed by the hot-rolled double-layer bimetallic compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com