Cleaning tank

A technology for cleaning tanks and tank bodies, applied in the field of cleaning tanks, can solve the problems of reduced strip production efficiency, increased strip production costs, damage to cleaning tank spray pipes and nozzles, etc., to reduce production costs and improve strip production Efficiency, the effect of preventing stacking of steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

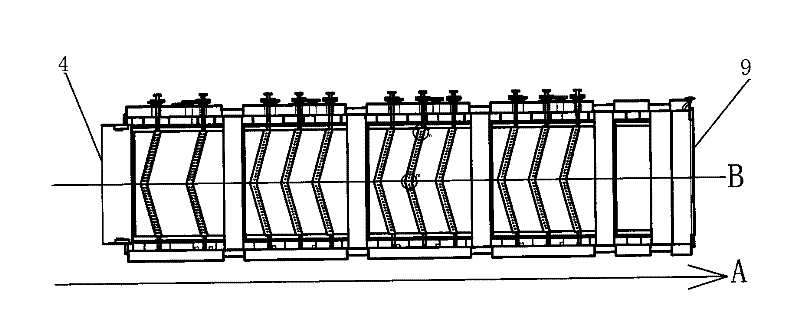

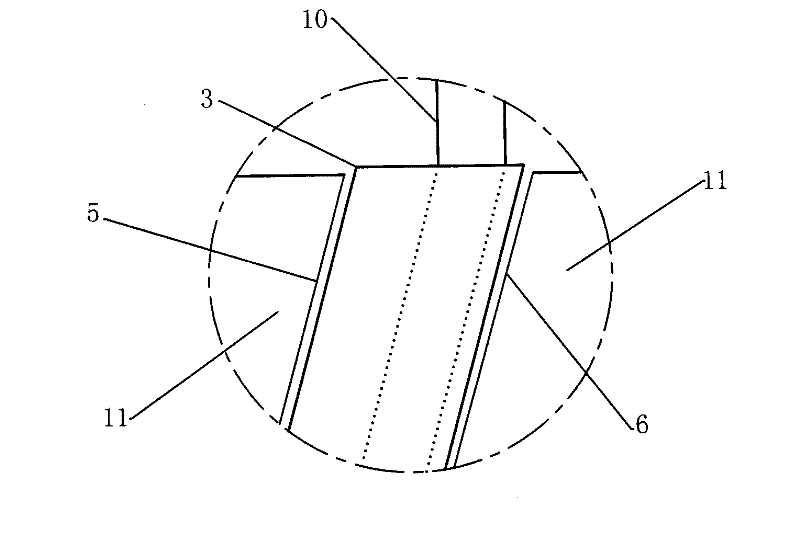

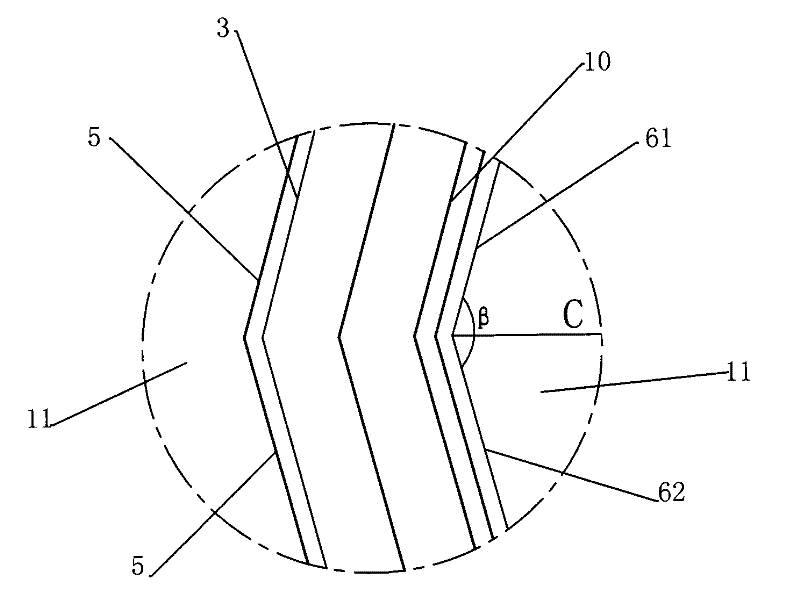

[0021] The present invention will be further described in conjunction with accompanying drawing:

[0022] like Figure 1 to Figure 5 As shown, the cleaning tank of this embodiment includes a tank body 1 and a tank cover 2 that seals the tank body 1, and the adjoining part of the tank body 1 and the tank cover 2 is sealed with water. When steam is passed inside, the leakage of steam can be effectively reduced; a strip steel guide plate 11 is installed in the tank body 1, and the strip steel guide plate 11 includes an upper guide plate 7 and a lower guide plate 8, and the upper guide plate 11 Form strip channel between guide plate 7 and described lower guide plate 8; And the distance between described upper guide plate 7 and described lower guide plate 8 is 50 millimeters, the thickness that is suitable for strip steel is 1.8 millimeters-4 mm; along the moving direction A of the strip: the adjoining sides of the two adjacent upper guide plates 7 are respectively the head side 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com