High-wear-resistant combined type coiling machine side guide plate

A coiler and combined technology, applied in the field of coilers, can solve problems such as scratches, continuous welding material falling off, and steel coil slag quality accidents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

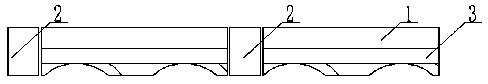

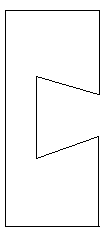

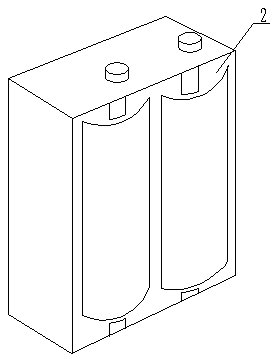

[0031] Such as Figure 1 to Figure 3 As shown, a side guide plate of a high wear-resistant combined coiler includes a lining plate 1 and a side guide wheel 2 arranged at intervals on both sides of the coiler conveying roller table, and a side guide wheel 2 is arranged at the entrance. The wear-resistant alloy strip 3 is installed on the liner 1, the thickness of the wear-resistant alloy strip 3 is 10-12mm, the surface hardness value is 50-70HRC, the tensile strength is 1400-1800MPa, the chemical composition and the weight percentage of each composition are: C: 0.2 %-1.0%, TiC: 30-50%, Cr: 2.0-5.0%, Mo: 2.0-5.0%, and the rest is Fe element. The preparation method of wear-resistant alloy strip 3 includes:

[0032] 1) Compression molding: mix the alloy element powders of the wear-resistant alloy strip 3 according to the proportion, and press them into the desired shape under a pressure of 100-300 MPa. The particle size of the alloy element powders of the wear-resistant alloy stri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com