Security air jet loom

An air-jet loom, safety technology, applied in textiles, textiles and auxiliary equipment for papermaking and weaving, etc., can solve problems such as hidden safety hazards in production workshops, negative effects on workers' health, spontaneous combustion in case of fire, etc., to reduce the difficulty of cleaning, The effect of avoiding health threats and ensuring air quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

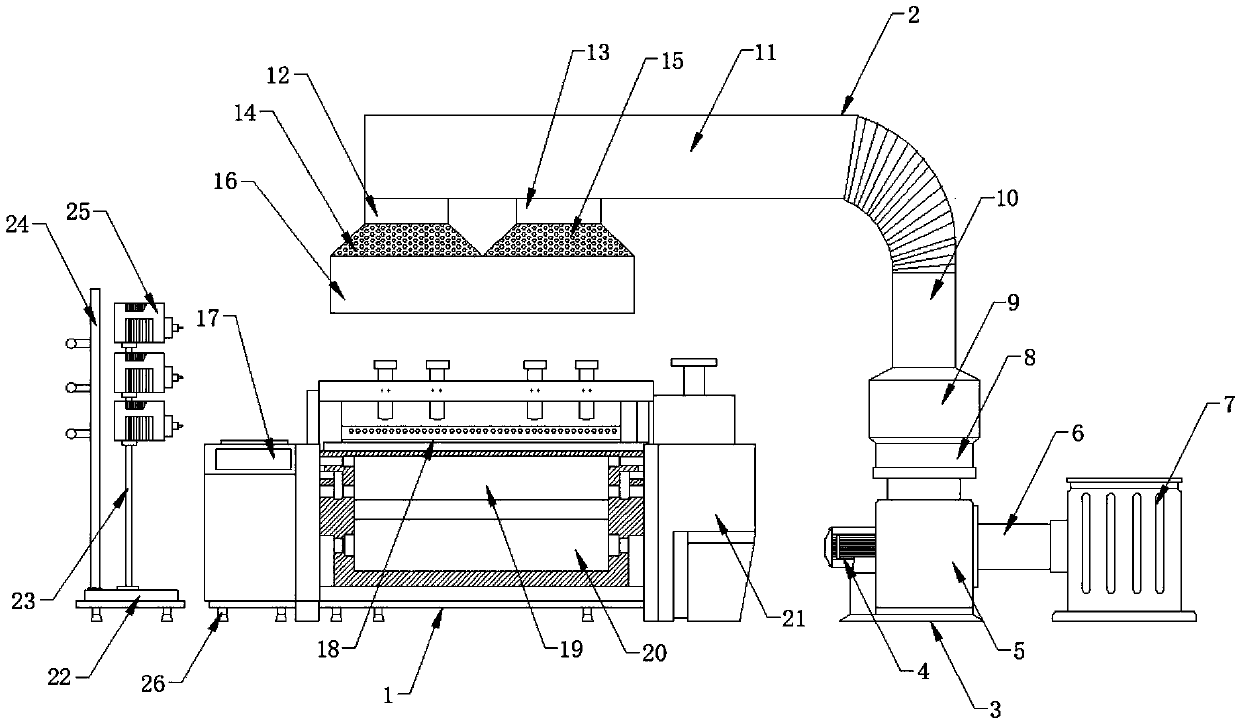

[0018] Such as figure 1 As shown, the present invention provides a safe air-jet loom, comprising a loom body 1 and a dust cleaning group 2, the dust cleaning group 2 is arranged at one end of the loom body 1, the dust cleaning group 2 is provided with a suction fan 3, and the suction fan 3 includes a suction motor 4 and a suction box 5, one end of the suction fan 3 is fixedly connected with a discharge pipe 6, the other end of the discharge pipe 6 is fixedly connected with a storage box 7, and the top of the suction fan 3 is provided with a fan suction port 8 , a buffer box 9 is fixedly installed on the top of the fan suction port 8, and the top of the buffer box 9 is fixedly connected with a bronchial pipeline 10, and the suction fan 3 sucks to collect the fluff produced by the loom, and part of the fluff temporarily stays in the buffer box 9 to prevent the blower from blowing. Blockage, material storage box 7 is convenient to collect fluff.

[0019] Further, the other end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com