A Nozzle Thermal Insulation Structure for Thrust Steering Jet Engine

A jet engine and thrust technology, applied in the direction of machine/engine, jet propulsion, etc., can solve the problems of few achievements, complex three-bearing steering nozzle structure, and few test groups, so as to reduce the dependence of facilities and improve the response speed. and maneuverability, good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be further described below in conjunction with the accompanying drawings.

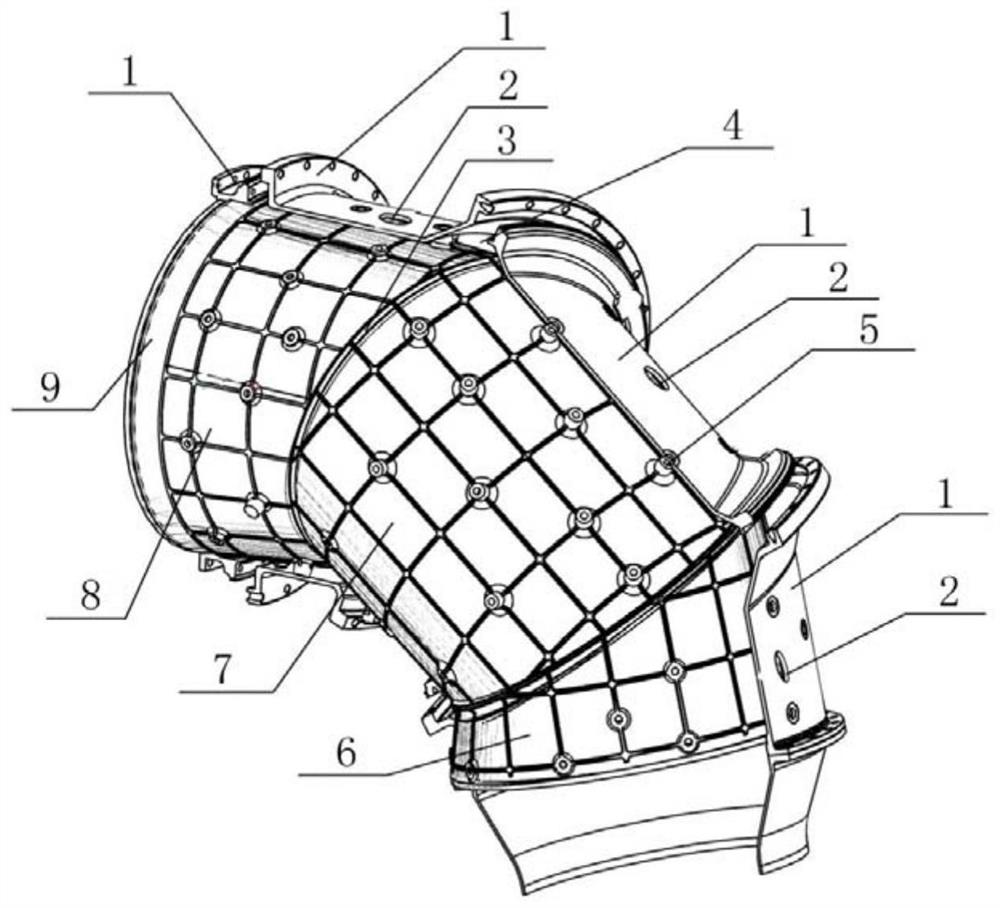

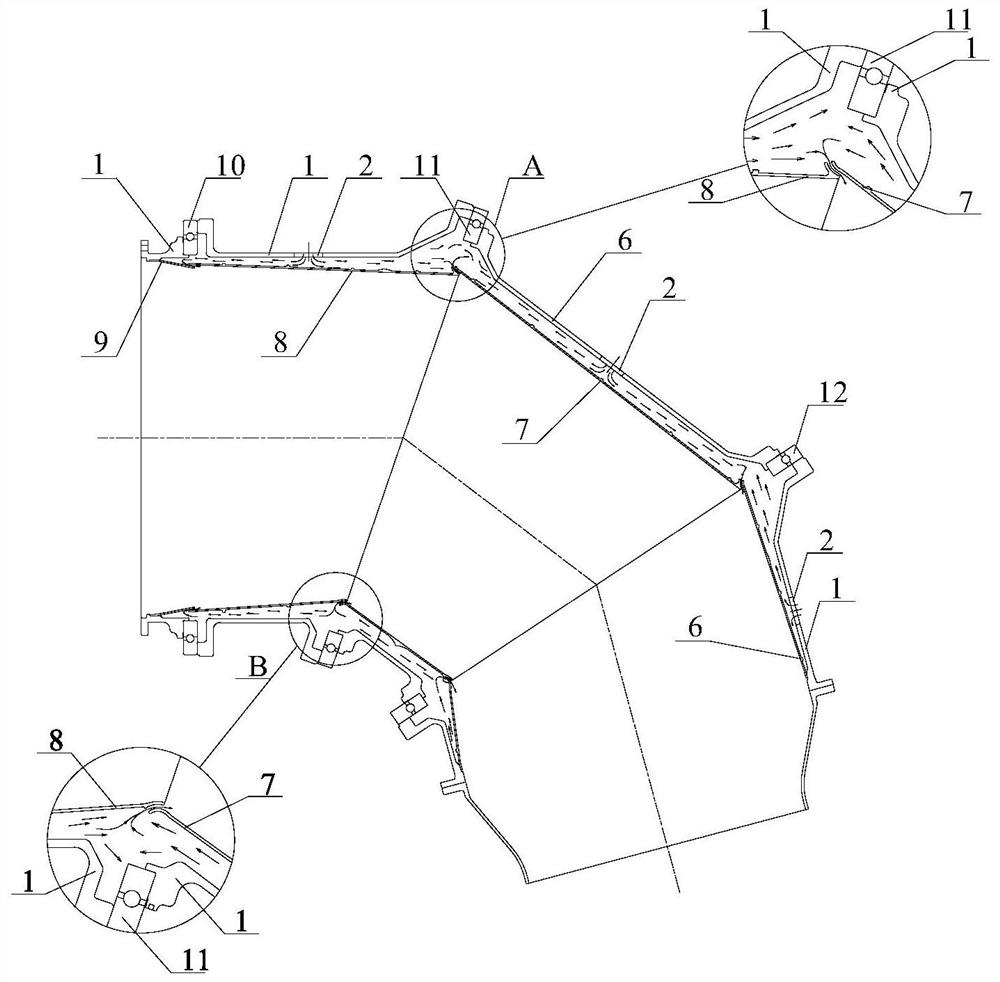

[0054] See attached figure 1 ~ attached image 3 , a nozzle heat insulation structure for a thrust steering engine, including 1# heat shield, 2# heat shield, 3# heat shield, 4 heat shield, elastic connection kit, heat shield lap structure , air-introduction holes, the heat shields 1# to 4# are integral structural parts, a cooling chamber is formed between the heat shield and the outer cylinder, the heat shield is connected to the outer cylinder through an elastic connection kit, and the elastic connection kit is used to connect the heat shield to the outer cylinder. The elastic element in the middle counteracts the thermal expansion of the heat-insulating outer cylinder.

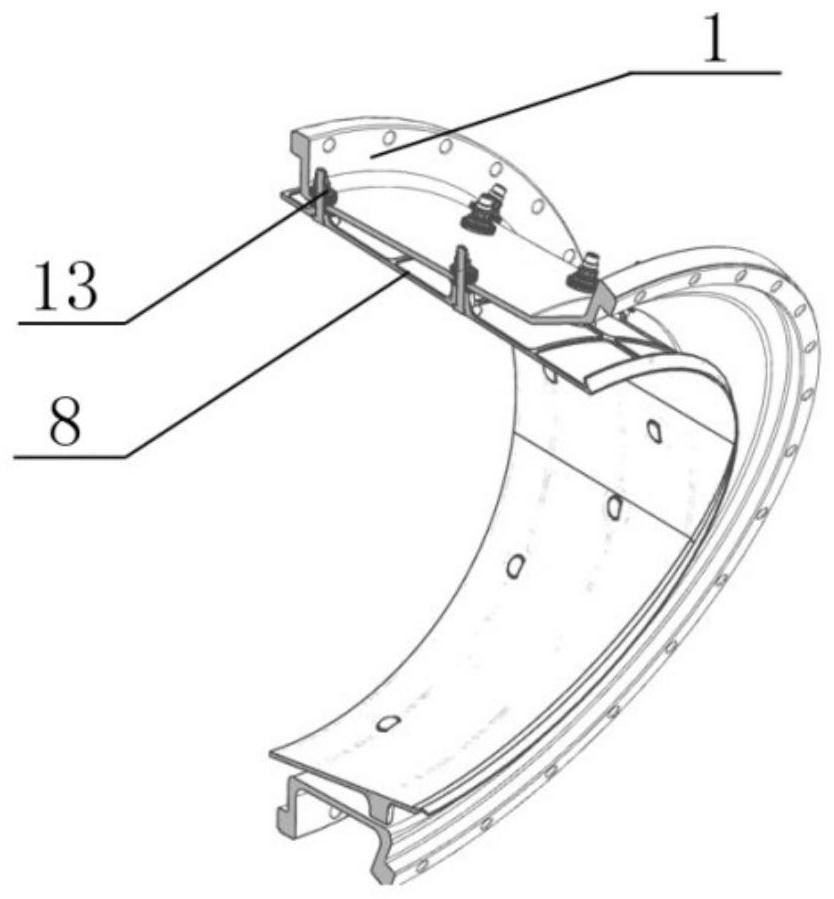

[0055] See attached Figure 4 ~ attached Figure 6 , the outer wall of the heat shield facing the side of the cooling chamber is designed with reinforced ribs, which are evenly distributed vertic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com