Modular low-pressure cutting type gas explosion valve

A modular, low-pressure technology, used in safety valves, balance valves, valve devices, etc., can solve problems such as inability to meet long-term storage requirements and high reliability, unstable rupture diaphragm rupture pressure, and difficulty in diaphragm production. Achieve the effect of light weight, simple structure and improved reliability of action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings.

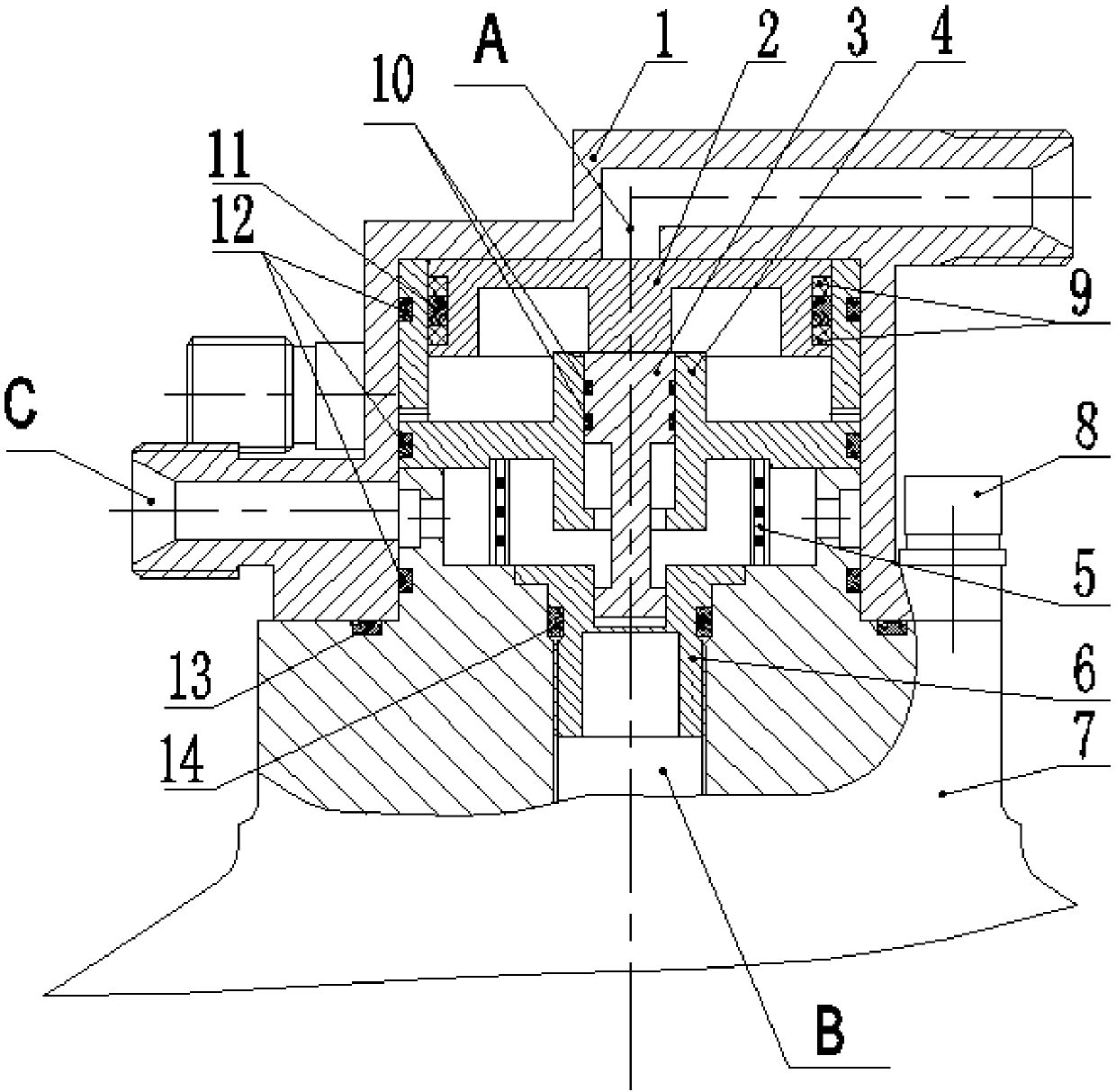

[0016] Such as figure 1 As shown, the embodiment of the present invention provides a modular low-pressure cut-off gas explosion valve, including a storage tank 7 with an O-ring V13 connected together by a connecting screw 8, a filter screen 5 and a housing 1; The housing 1 is provided with a guide sleeve 4 with an O-ring III12, and the guide sleeve 4 is provided with a piston 2 with a retaining ring 9 and an O-ring II11 and a cutter with a double-channel O-ring I10 3. A diaphragm 6 with an O-ring IV14 is installed in the storage tank 7, and the cutter 3 is fixed above the diaphragm 6 through a limit ear. Uniform diaphragm; also includes an air chamber A arranged on one side of the upper end of the housing 1, a downstream pipeline C on both sides of the inner lower end, and a liquid chamber B arranged at the lower end of the storage tank 7, and the fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com