Preparation method of two-dimensional conductive polymer solar light absorber for solar water vapor evaporation

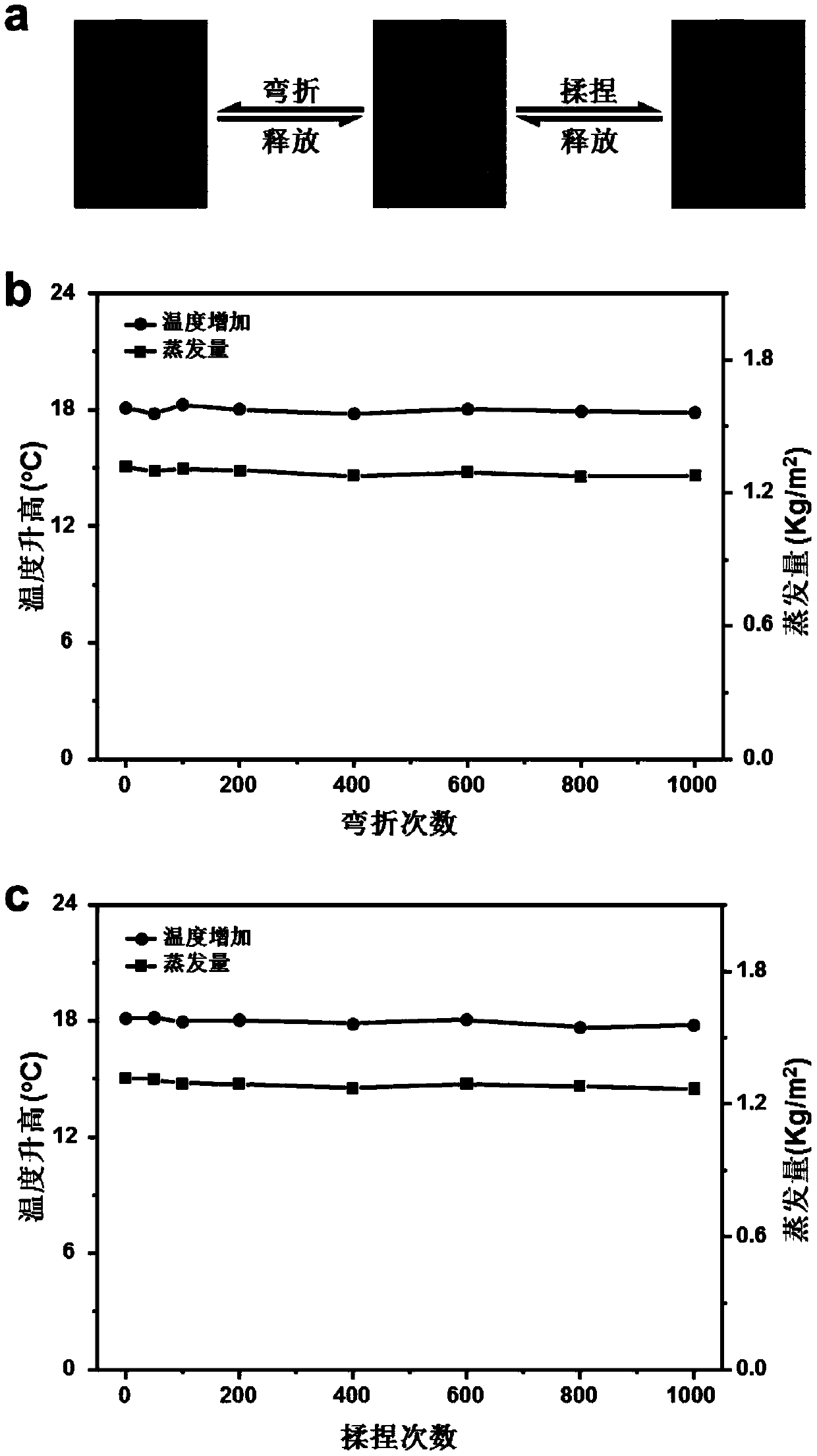

A conductive polymer, sunlight technology, applied in the field of solar water vapor evaporation, can solve the problems of high cost, difficult to use in large-scale commercial use, poor flexibility, etc., and achieves a simple preparation method, excellent seawater desalination and decontamination water purification. , the effect of excellent stability and flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] In a 50ml beaker, dissolve 1.2g of ammonium persulfate (purchased from Aladdin) in 10ml of deionized water to prepare a 120mg / ml ammonium persulfate aqueous solution, and pass the obtained ammonium persulfate aqueous solution through a pipette Add it dropwise to a dust-free paper (0609D dust-free paper) with a diameter of 5 cm until the entire dust-free paper is wetted by ammonium persulfate aqueous solution.

[0060] Then, spread the wetted dust-free paper on the smooth and flat surface of the ice cube, and then add pyrrole (purchased from Aladdin Company) drop by drop on the dust-free paper through a pipette to carry out the polymerization reaction , After 1 min, the surface of the dust-free paper can be seen to be blackened (that is, covered with a black layer), indicating that the polymerization reaction is completed.

[0061] Use tweezers or hands to remove the dust-free paper covered with a black layer from the ice cube, wash it twice with deionized water, and the...

Embodiment 2-5

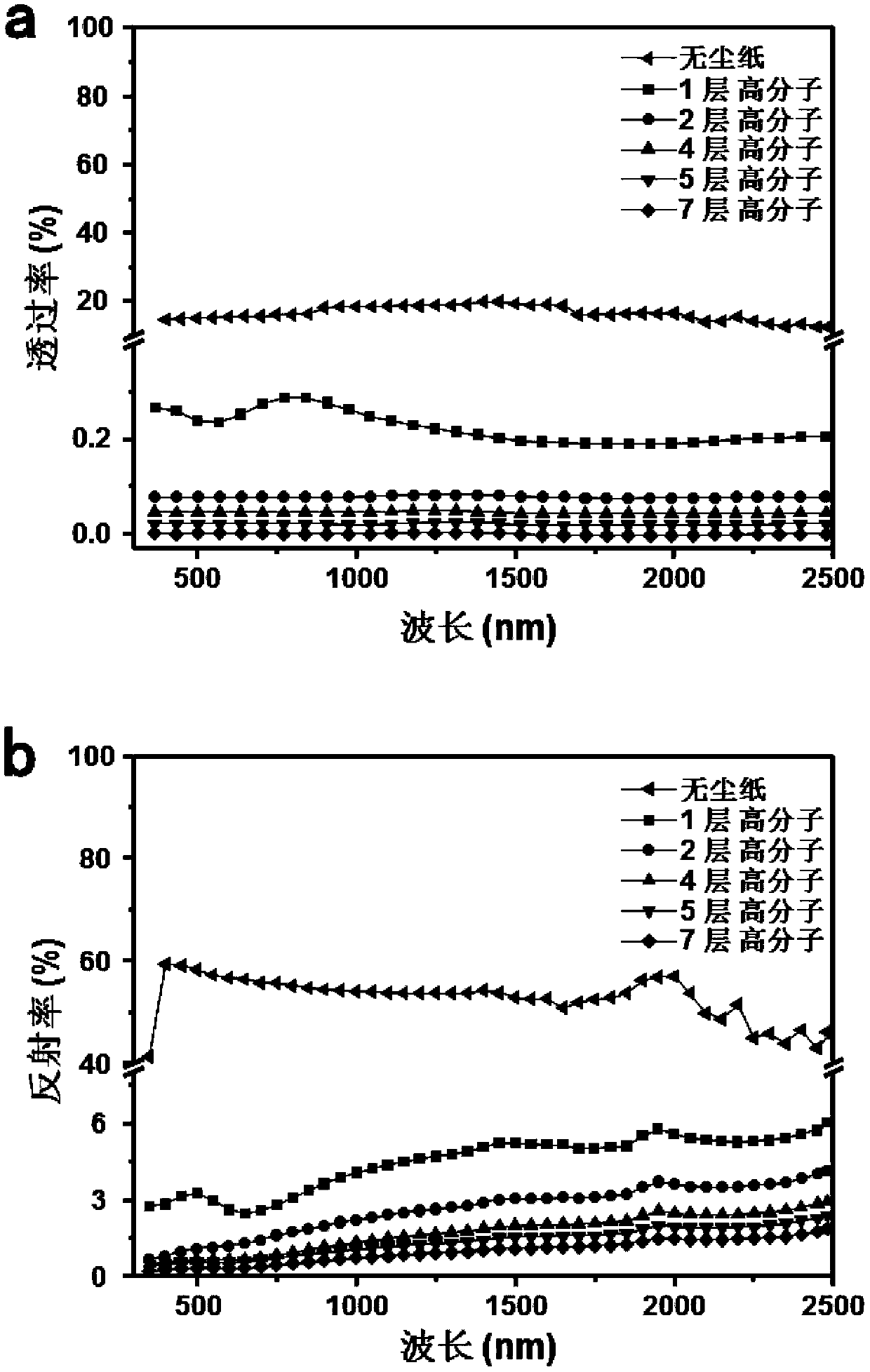

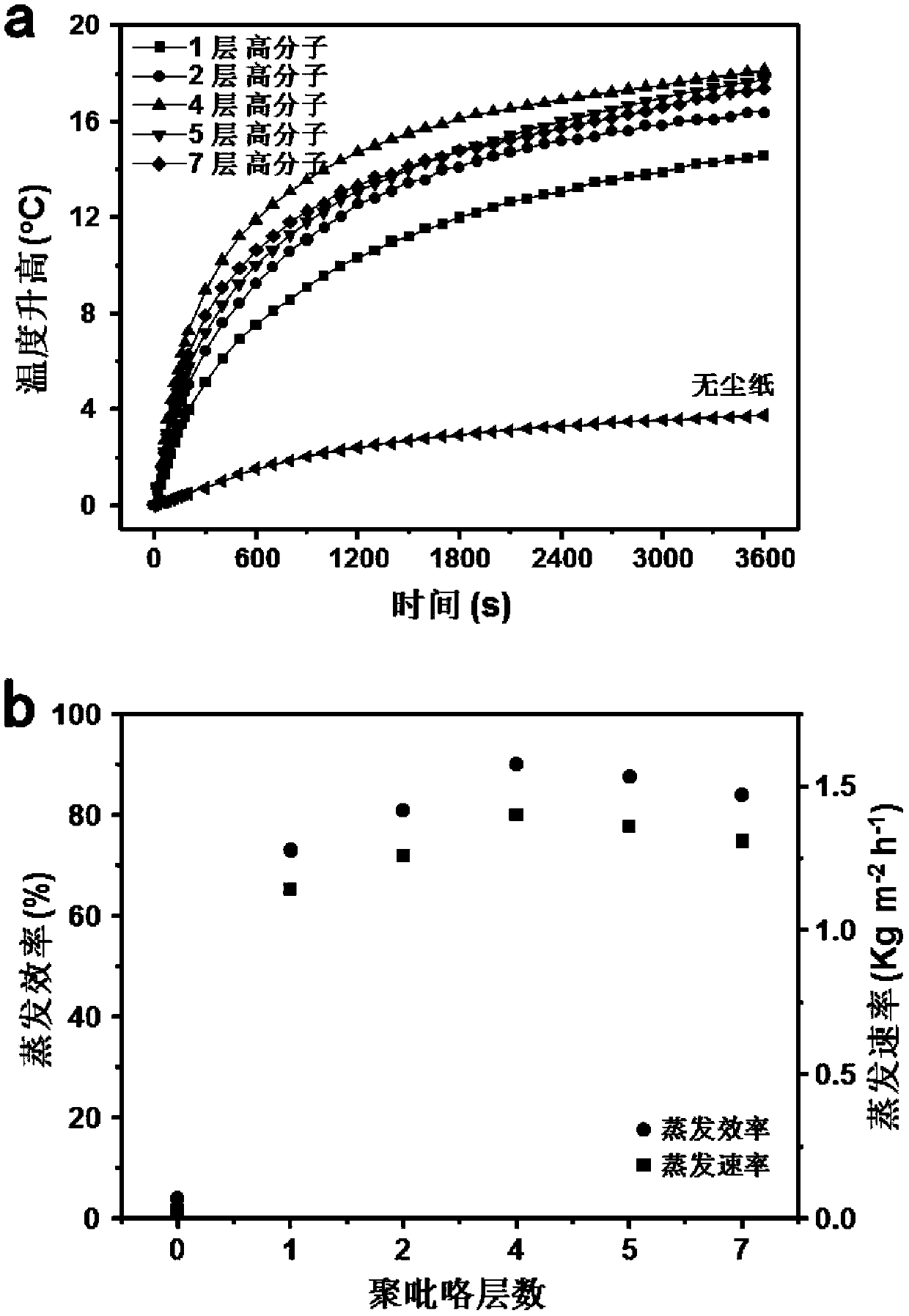

[0063] Carry out the experiment in a manner similar to Example 1, the difference is that the 1-layer two-dimensional conductive polymer solar light absorber obtained by drying in Example 1 is used as a substrate, and the polymerization and The drying steps were repeated 1, 3, 4 and 6 times respectively to obtain 2-layer, 4-layer, 5-layer and 7-layer two-dimensional conductive polymer solar light absorbers (referred to as 2-layer polymer and 4-layer polymer respectively). , 5-layer polymer and 7-layer polymer).

Embodiment 6

[0073] In a 500ml beaker, by dissolving 1.2g ferric chloride powder (purchased from Aladdin Company) in 10ml hydrochloric acid (purchased from Sinopharm Reagent Company; concentration 36%), a mixed solution of ferric chloride hydrochloric acid was obtained, and the obtained The mixed solution was added dropwise to a qualitative filter paper with a diameter of 5 cm (purchased from Sinopharm Reagent Company) through a pipette until the entire qualitative filter paper was wetted by the mixed solution.

[0074] Then, spread the wetted qualitative filter paper on the smooth ice cube surface, then add pyrrole (purchased from Aladdin Company) drop by drop on the qualitative filter paper by pipette to carry out the polymerization reaction. After 2 minutes, the surface of the qualitative filter paper can be seen to be blackened (that is, covered with a black layer), indicating that the polymerization reaction is completed.

[0075] With tweezers or hands, the qualitative filter paper c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com