Coating cooling equipment

A technology for cooling equipment and coatings, applied in lighting and heating equipment, household refrigeration devices, household appliances, etc., can solve problems such as coating cooling, save costs, make full use of resources, and enhance the effect of cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following is further described in detail through specific implementation methods:

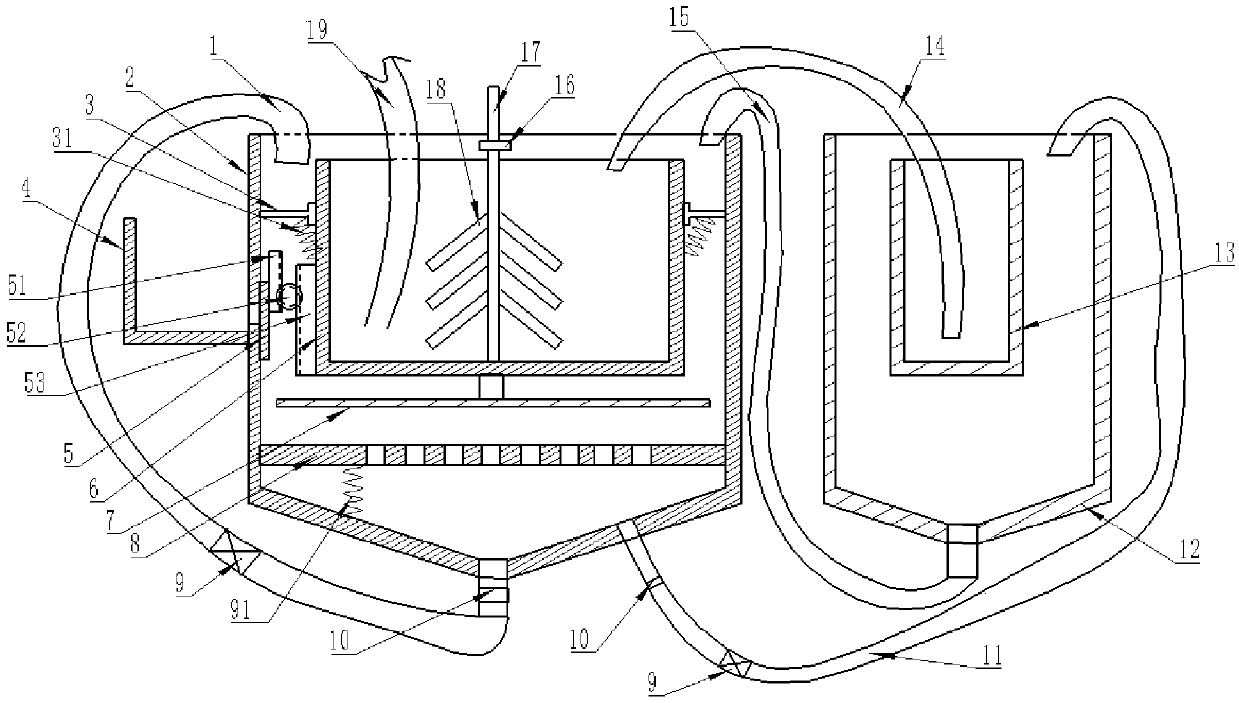

[0021] The reference signs in the drawings of the description include: circulation pipe 1, main cooling bucket 2, positioning ring 3, first elastic member 31, ice chamber 4, baffle plate 5, closing rack 51, gear 52, pushing rack 53, Main paint tank 6, pressure plate 7, drain plate 8, one-way valve 9, second elastic member 91, pressure valve 10, drain pipe 11, preliminary cooling tank 12, preliminary paint tank 13, feeding pipe 14, salt adding pipe 15 , Nut 16, leading screw 17, stirring rod 18, discharge pipe 19.

[0022] The embodiment is basically as attached figure 1 Shown: a coating cooling device, including a main cooling barrel 2, an ice chamber 4 is arranged on the left side of the main cooling barrel 2, ice cubes are preset in the ice chamber 4, and a The ice inlet is connected with the ice chamber 4, and the inner wall of the main cooling barrel 2 is slidably connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com