Battery pack cycle test consistency analysis method

A technology of cyclic testing and analysis methods, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve the problems of inaccuracy, not considering the state of charge, etc., to achieve the effect of getting rid of rummaging data and drawing smoothly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

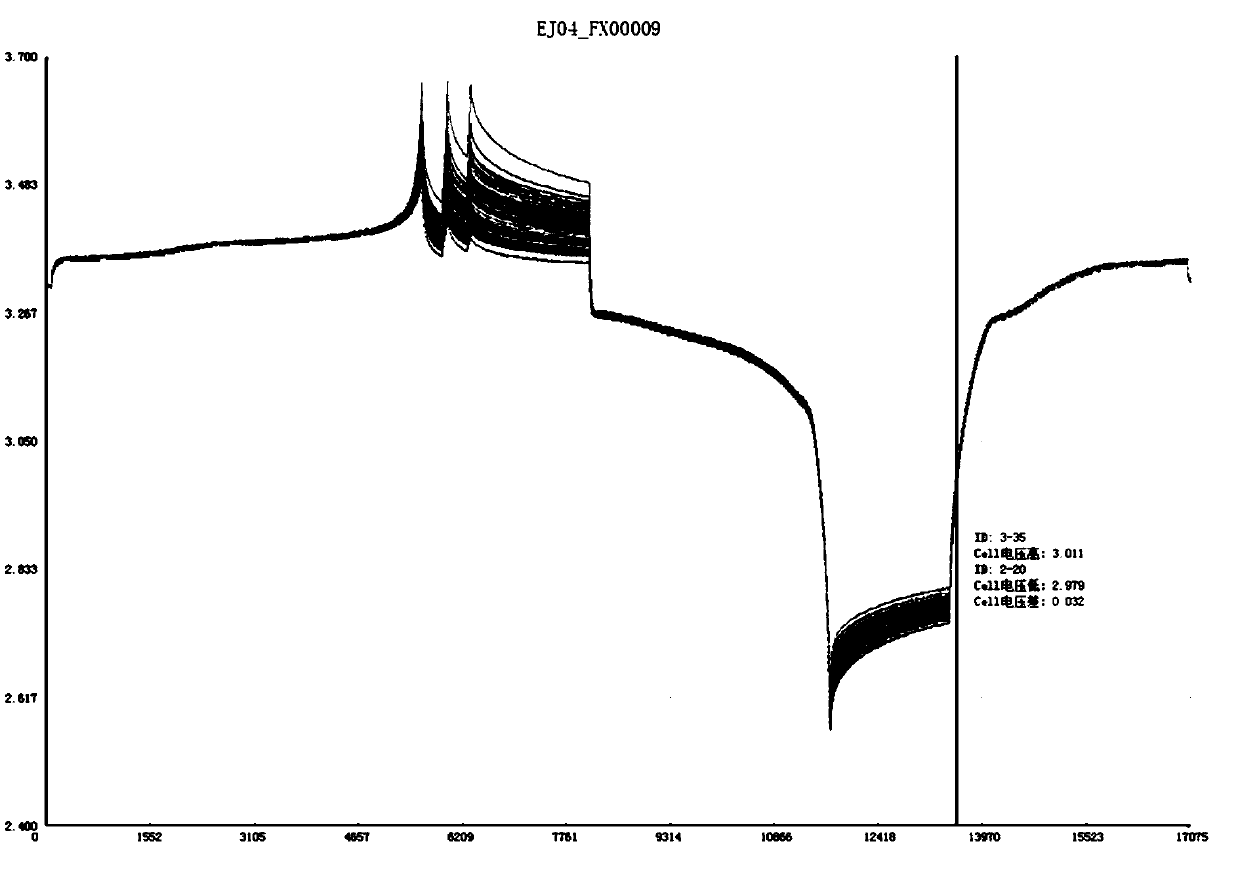

Image

Examples

Embodiment Construction

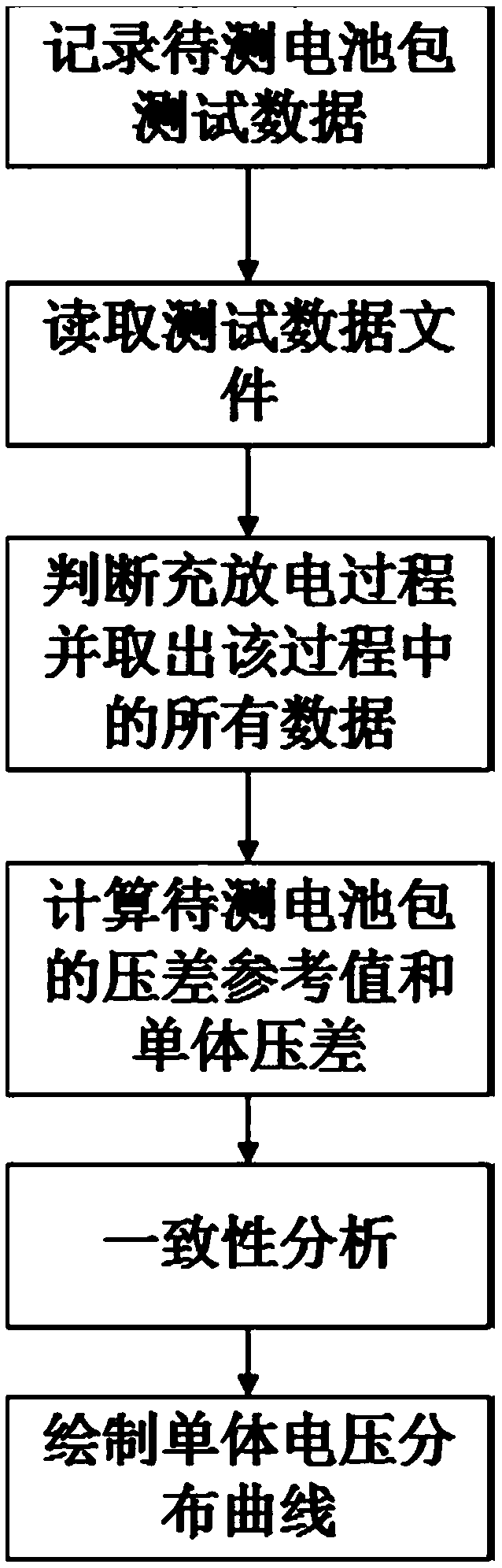

[0026] Such as figure 1 As shown, the workflow of the battery pack cycle test consistency analysis system includes:

[0027] 1. The data storage unit records the test data of the battery pack according to the preset time interval and format.

[0028] 2. Read the test data file, read all the data according to the meaning of each data column configured in advance, and load the data into the system memory for subsequent system analysis of product consistency and drawing of voltage trend diagrams.

[0029] 3. Determine the charging and discharging process. There are two ways to identify the charge and discharge state of the battery pack: current method and voltage method. In the case of current records, the current charging and discharging state of the product can be distinguished through the change of current data. In a static state, the current value is 0 or a very small absolute value; when charging or discharging, the current value is positive or negative. In the absence o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com