De-sheathing device for optical cable

A technology for sheathing and optical cables, which is applied in the field of sheathing devices and optical cable sheathing devices, which can solve the problems of large size and inconvenience for users to carry around, and achieve the effect of compact structure, convenient use and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

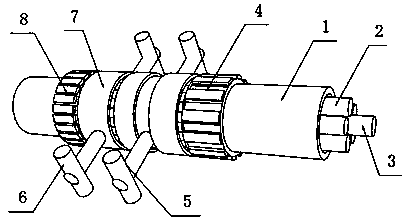

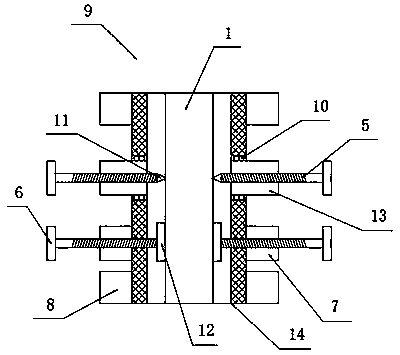

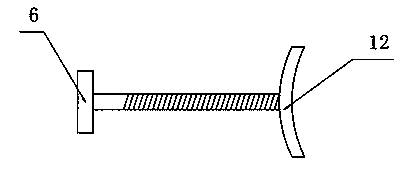

[0021] Such as Figure 1-3 As shown, a kind of sheath removal device for optical cable includes optical cable 1 and sheath removal device 9, loose tube 2 is arranged inside optical cable 1, central strengthening core 3 is arranged inside loose tube 2, and sheath removal device 9 consists of The cylinder body 14 is composed of a fixed ring 8 arranged on the side wall of the cylinder body 14, a connecting ring 7 is arranged above the fixed ring 8, a rotating ring 13 is arranged above the connecting ring 7, balls 10 are arranged on the upper and lower sides of the rotating ring 13, and a second ring is arranged inside the connecting ring 7. Two rotating handles 6, a fixed plate 12 is installed at one end of the second rotating handle 6, a first rotating handle 5 is arranged inside the rotating ring 13, a cutting knife 11 is installed at one end of the first rotating handle 5, and anti-slip lines 4 are provided on the side wall of the fixing ring 8. The fixed plate 12 is fixedly c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com