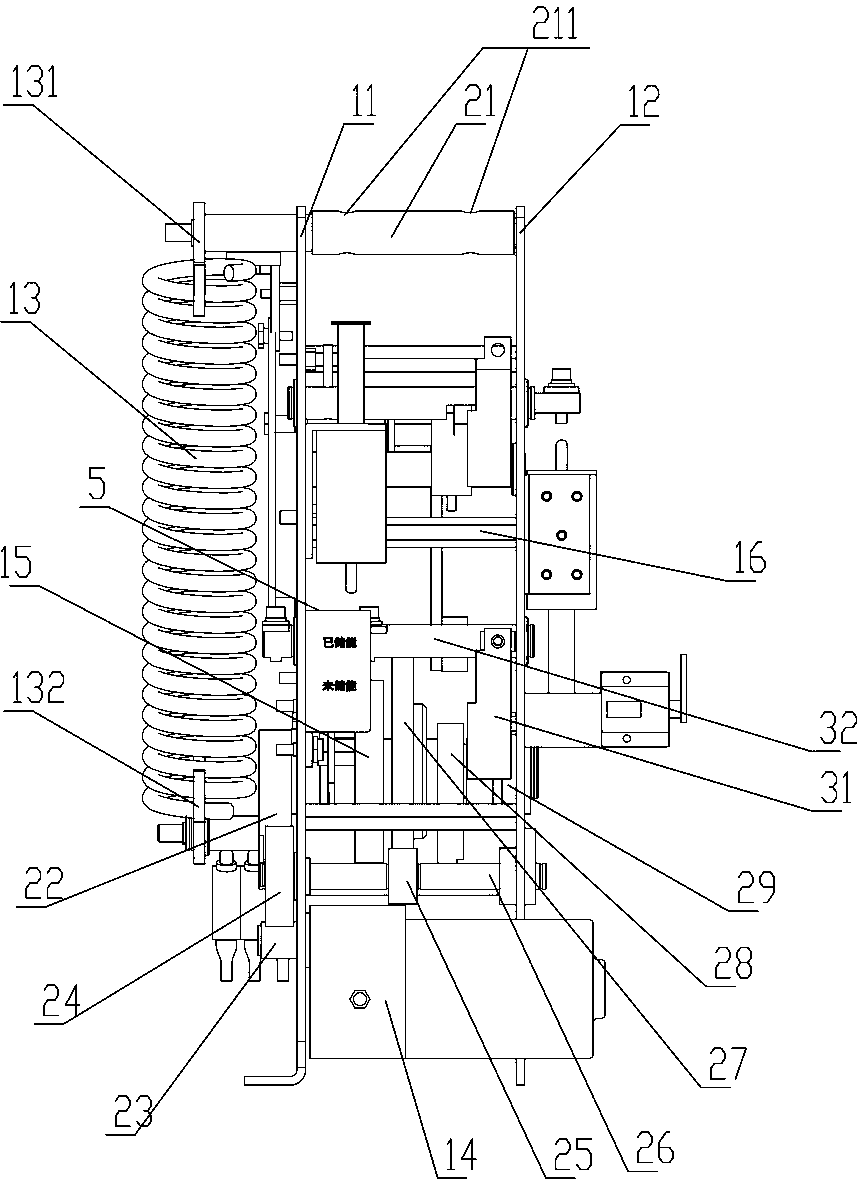

Assembled spring operating mechanism

An operating mechanism and assembled technology, which is applied to the contact operating mechanism, power device inside the switch, electrical components, etc., can solve the requirements of high component strength, poor matching of output force characteristics and reaction force characteristics, and processing accuracy requirements of parts Advanced problems, to achieve the effect of reducing maintenance and repair time, improving reliability and economy, and ensuring assembly positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with specific examples.

[0031] as attached Figure 1-7 As shown, in this embodiment, an assembled spring operating mechanism includes a left splint 11, a right splint 12, and an energy storage transmission assembly arranged on a frame composed of the left splint 11 and the right splint 12, and the closing The transmission assembly, the opening transmission assembly, the output crank arm 17 and the closing spring 13; wherein the energy storage transmission assembly is arranged in the middle and lower part of the frame; the closing transmission assembly is arranged in the middle of the frame, the opening transmission assembly is arranged in the upper part of the frame, and the output crank The arm 17 is set between the closing transmission assembly and the opening transmission assembly, wherein the frame is connected by the left splint 11, the right splint 12 and the positioning installation shaft 21 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com