High-frequency AC rotating sliding arc discharging plasma generating system for methane dry reforming

A discharge plasma and methane dry reforming technology, applied in the direction of plasma, can solve the problems of heavy burden on discharge devices and high cost of magnets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

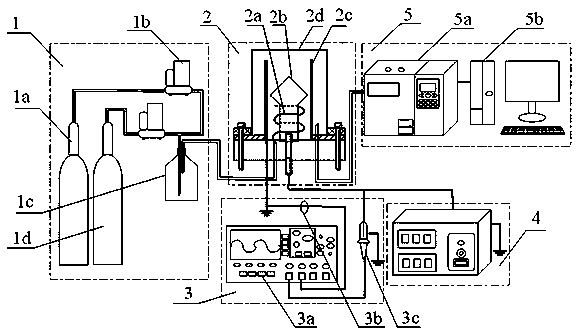

[0012] The technical solutions of the present invention will be clearly and completely described below in conjunction with the accompanying drawings.

[0013] figure 1 The working principle diagram of the high-frequency AC rotating sliding arc discharge plasma generation system for methane dry reforming is shown. In the figure, this high-frequency AC rotary sliding arc discharge plasma generation system for methane dry reforming includes a gas distribution device 1 , a discharge device 2 , an electrical characteristic detection device 3 , a high-frequency AC power supply 4 and a product analysis device 5 . The gas distribution device 1 includes a carbon dioxide gas cylinder 1a, a methane gas cylinder 1d, a mass flow controller 1b and a gas mixing cylinder 1c. Bottle 1c is connected. The discharge device 2 includes a spiral glass tube 2a arranged in a glass cover 2d, a high voltage electrode 2b and a low voltage electrode 2c, the spiral glass tube 2a is set under the high vol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com