Airflow heating device

A technology of airflow heating and heating chamber, which is applied in the field of plastic particle drying and dehumidification equipment, which can solve the problems of high temperature and affecting the working status of heating equipment components, and achieve the effect of efficiently retaining heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

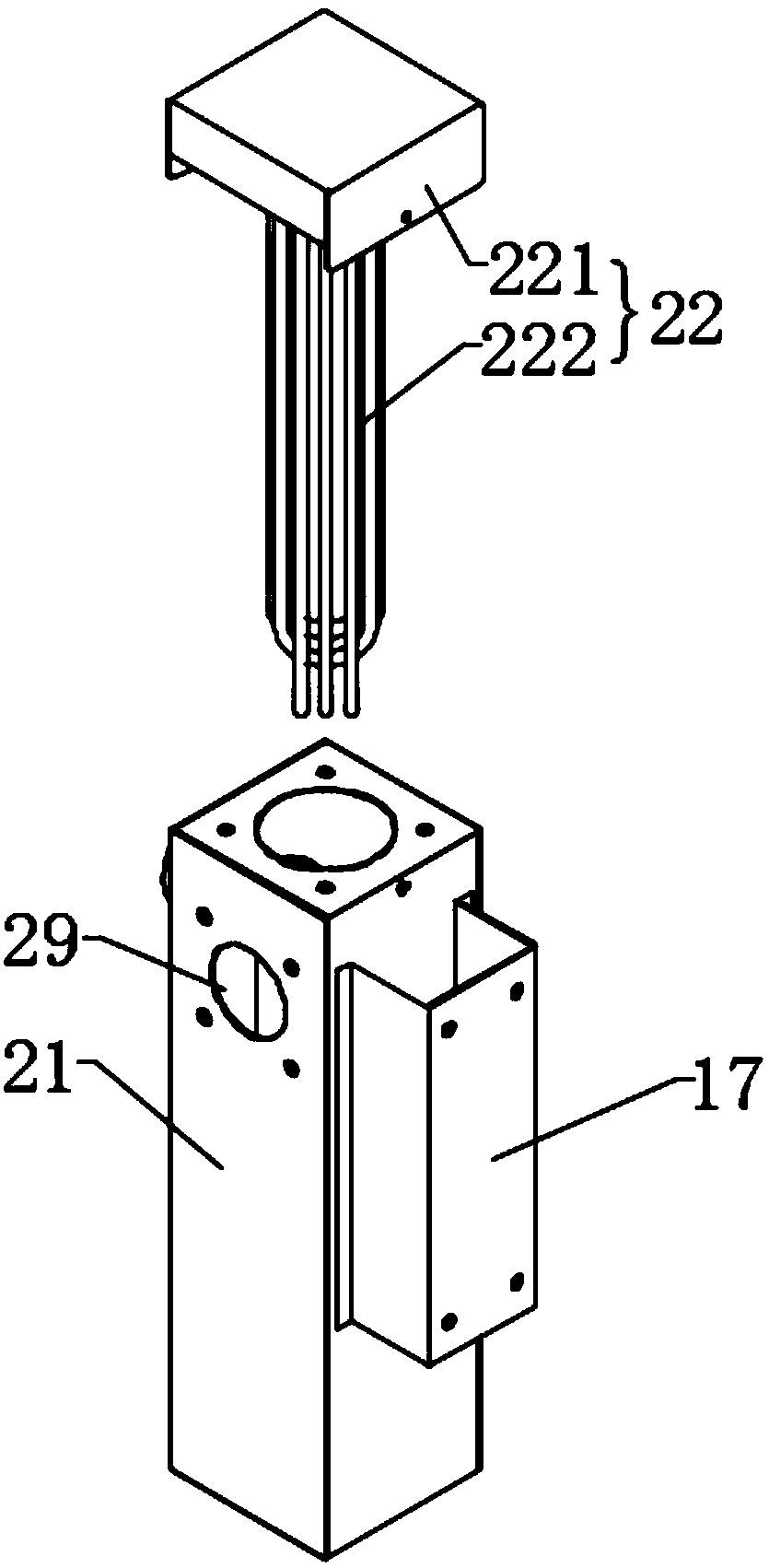

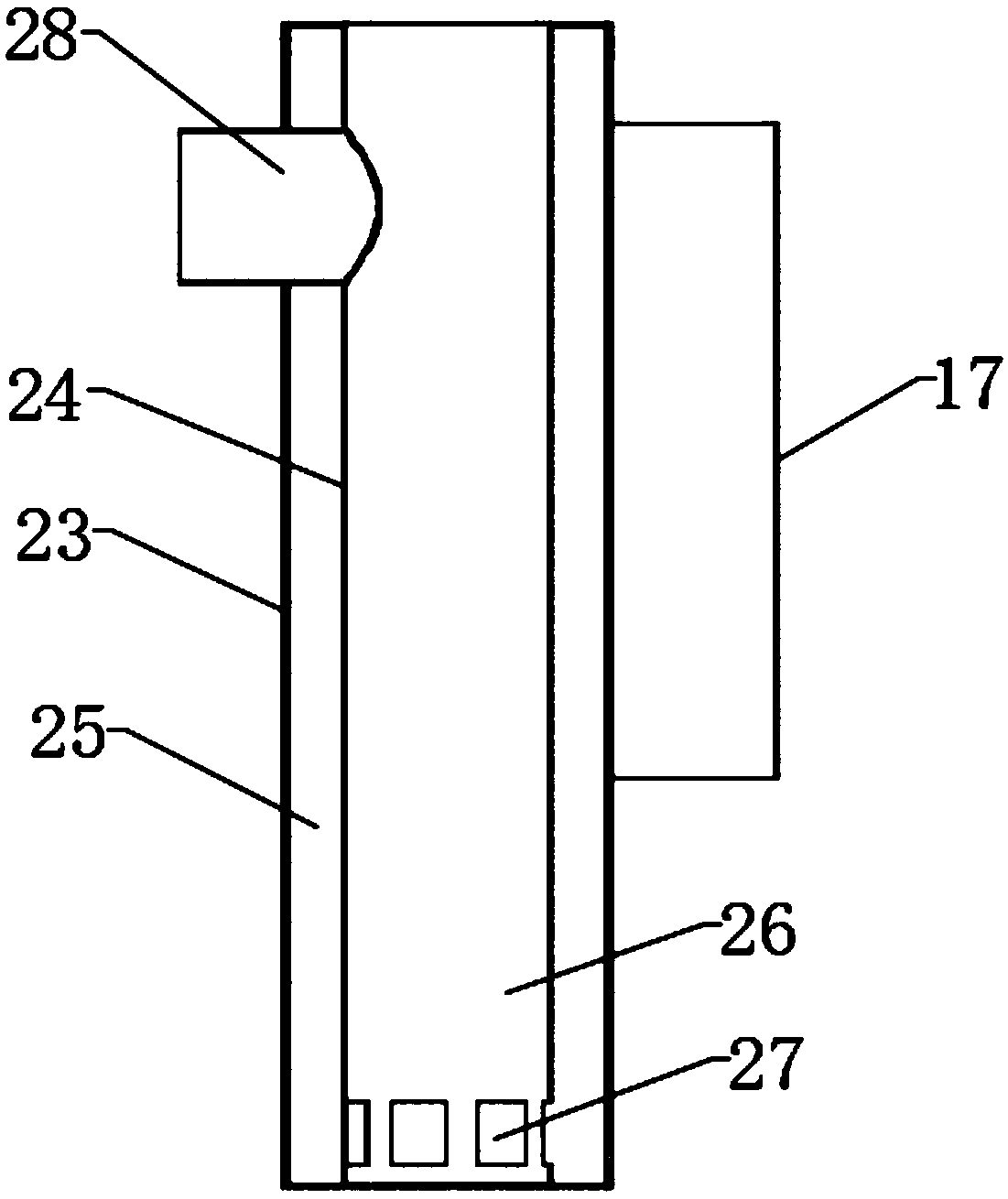

[0025] refer to figure 1 , is an exploded view of the structure of the airflow heating device; combined with figure 2 , is a schematic diagram of the cross-sectional structure of the heating box in the airflow heating device.

[0026] like figure 1 and figure 2 As shown in , the airflow heating device provided by the present invention is used in material drying and dehumidification equipment to heat the airflow passing through it. The airflow heating device includes:

[0027] The heating box 21 comprises an outer casing 23 and an inner casing, and a closed interlayer space 25 is provided between the outer casing 23 and the inner casing 24, a heating cavity 26 is formed in the inner casing 24, and the side wall of the inner casing 24 There is at least one air flow passage 27 connecting the interlayer space 25 and the heating chamber 26 on the top, an air inlet 29 connecting the interlayer space 25 and the outside is provided on the side wall of the outer shell 23, and a si...

Embodiment 2

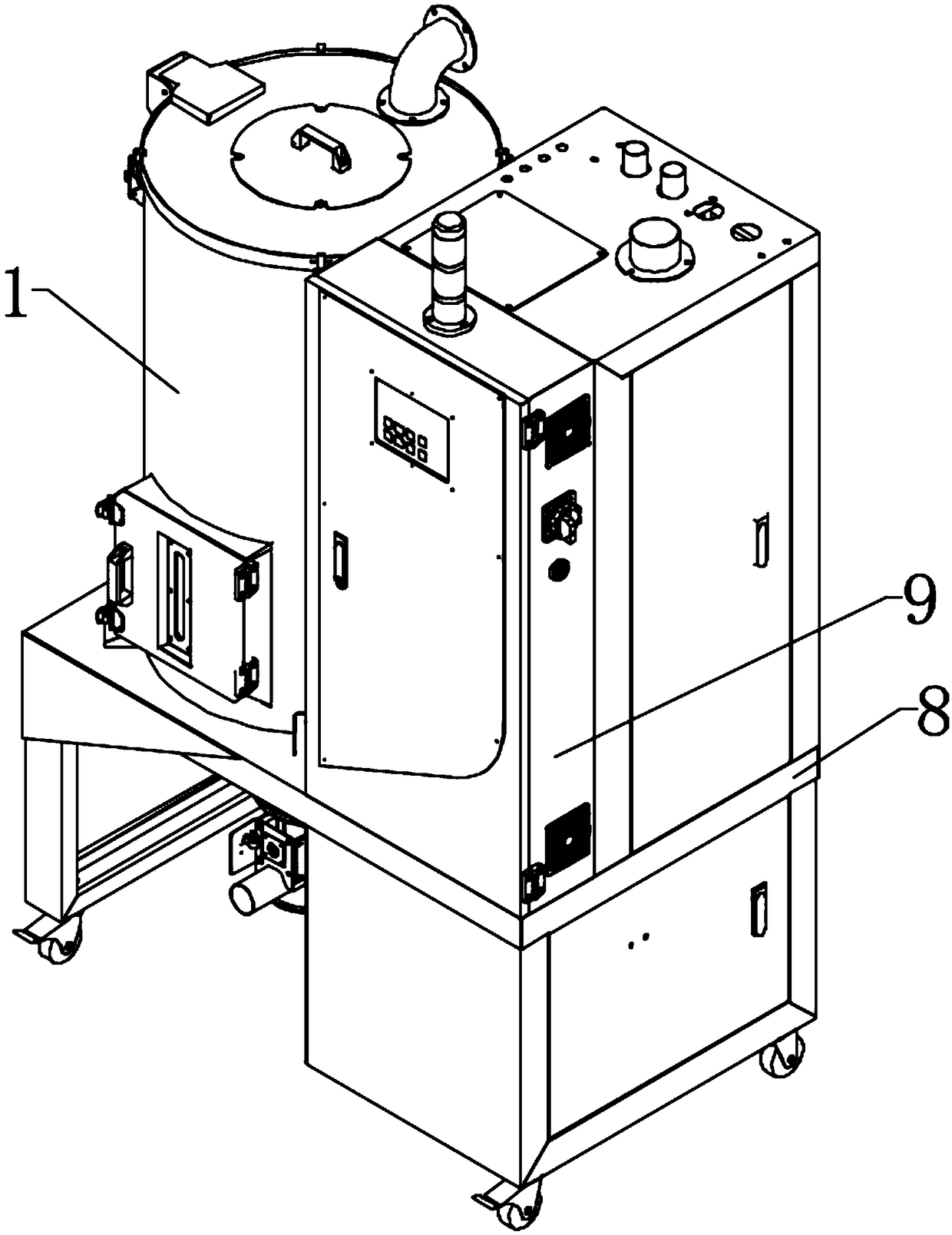

[0032] refer to image 3 , is a three-dimensional view of material drying and dehumidification equipment; combined with Figure 4 , a perspective view of the material drying and dehumidifying equipment after removing the outer casing; and Figure 5 , a perspective view of removing the outer casing and the barrel wall of the drying barrel for the material drying and dehumidifying equipment; and Image 6 , a side view of the material drying and dehumidifying equipment with the outer casing and drying barrel removed; and Figure 7 , is the working principle diagram of the material drying and dehumidification equipment, Figure 7 The direction of the arrow shown in is the direction of gas flow, and in order to show the structure of each component more clearly, in Figure 3 to Figure 6 The pipes used to communicate with the various components are omitted in the figure.

[0033] like Figures 3 to 7 As shown in , the present invention also provides a material drying and dehumid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com