Preparation device and method for continuous carbon fiber reinforced thermoplastic resin base prepreg sheet

A technology for enhancing thermoplasticity and preparing devices, which is applied in the direction of coating, etc., can solve the problems of low load-bearing capacity, difficulty in impregnating continuous carbon fiber with high-viscosity thermoplastic resin, and unstable mechanical properties of carbon fiber composite materials, etc., to achieve good designability, fiber The effect of precise content control and efficient production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

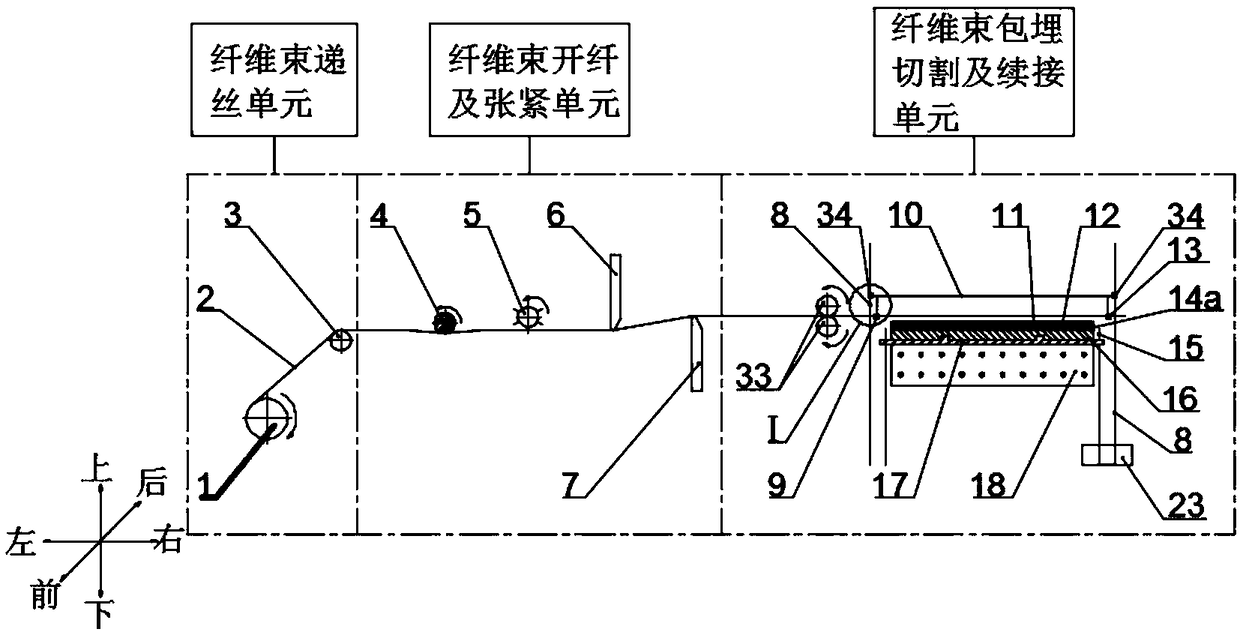

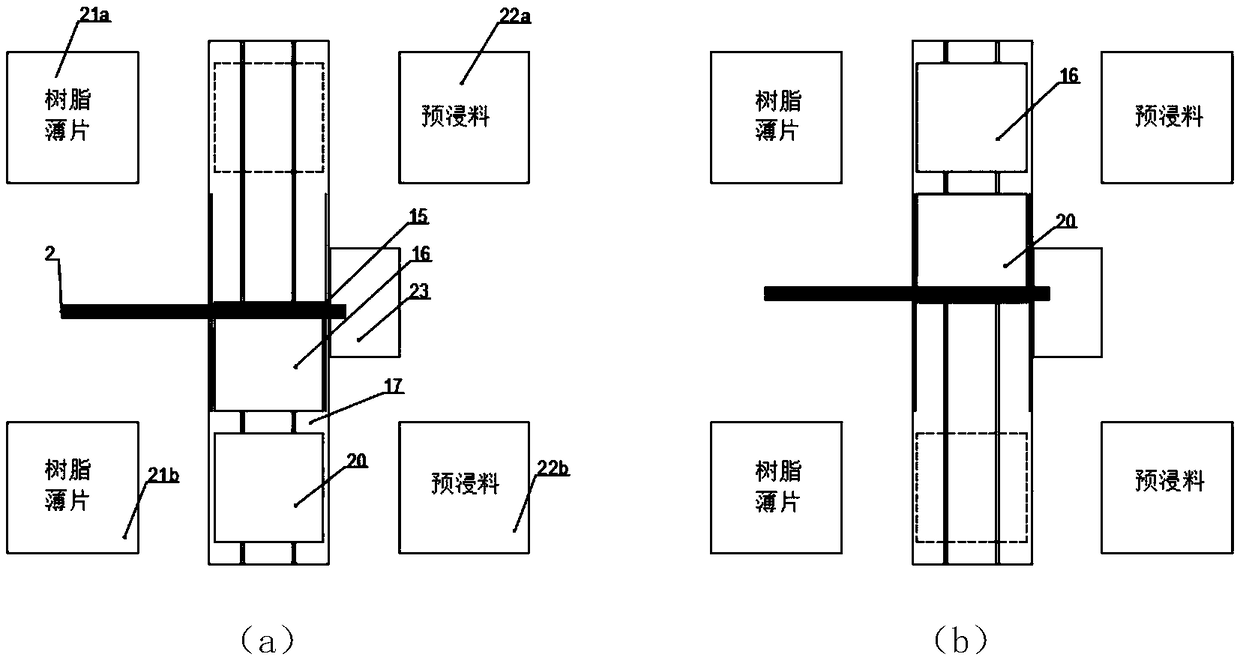

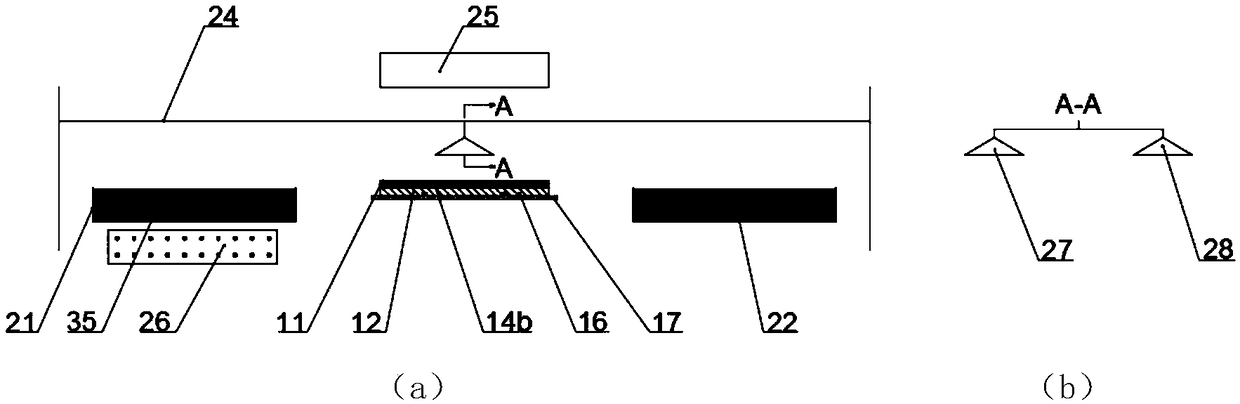

[0032] The present invention is a continuous carbon fiber reinforced thermoplastic resin-based prepreg preparation device, in order to facilitate the understanding of the structural features of the present invention, according to figure 1 Define the spatial orientation as shown in .

[0033] like Figure 1 to Figure 9 As shown, the continuous carbon fiber reinforced thermoplastic resin-based prepreg preparation device includes: fiber bundle delivery unit, fiber bundle opening and tensioning unit, fiber bundle embedding cutting and splicing unit, resin sheet heating and loading and unloading unit. Each of the above units is controlled by the main controller (model: FX3U-32MR / ES-A) to achieve coordinated operation and complete the preparation of continuous carbon fiber reinforced thermoplastic resin-based prepreg sheets.

[0034] like figure 1 As shown, the fiber bundle delivery unit includes: a carbon fiber bundle winding roller 1 on which a carbon fiber bundle 2 is wound and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com