Plastic bottle cap separating device

A separation device and plastic bottle technology, applied in the direction of plastic recycling, recycling technology, etc., can solve the problem of skin abrasion and other problems, achieve the effect of rapid separation and avoid skin abrasion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The following is further described in detail through specific implementation methods:

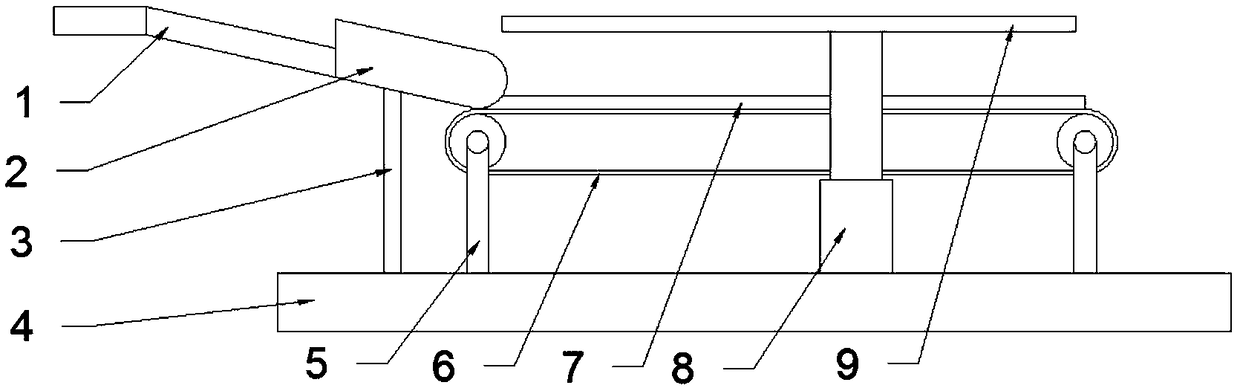

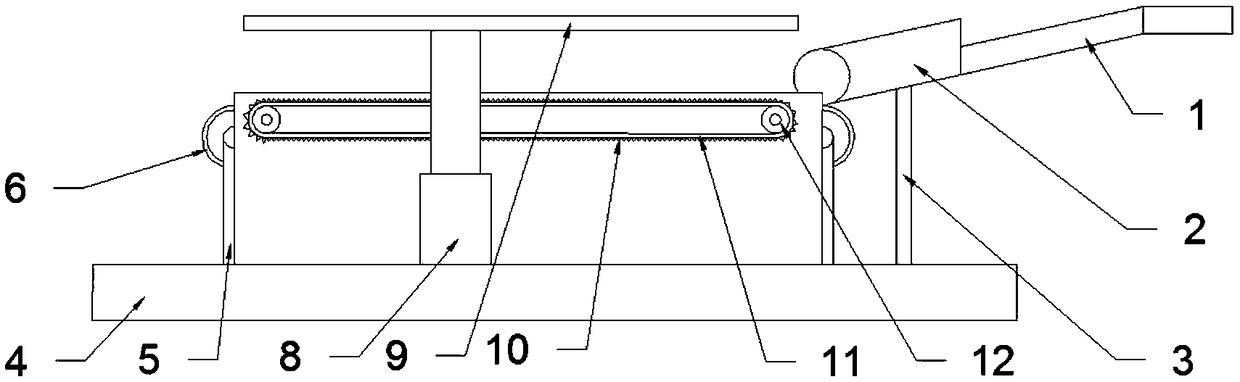

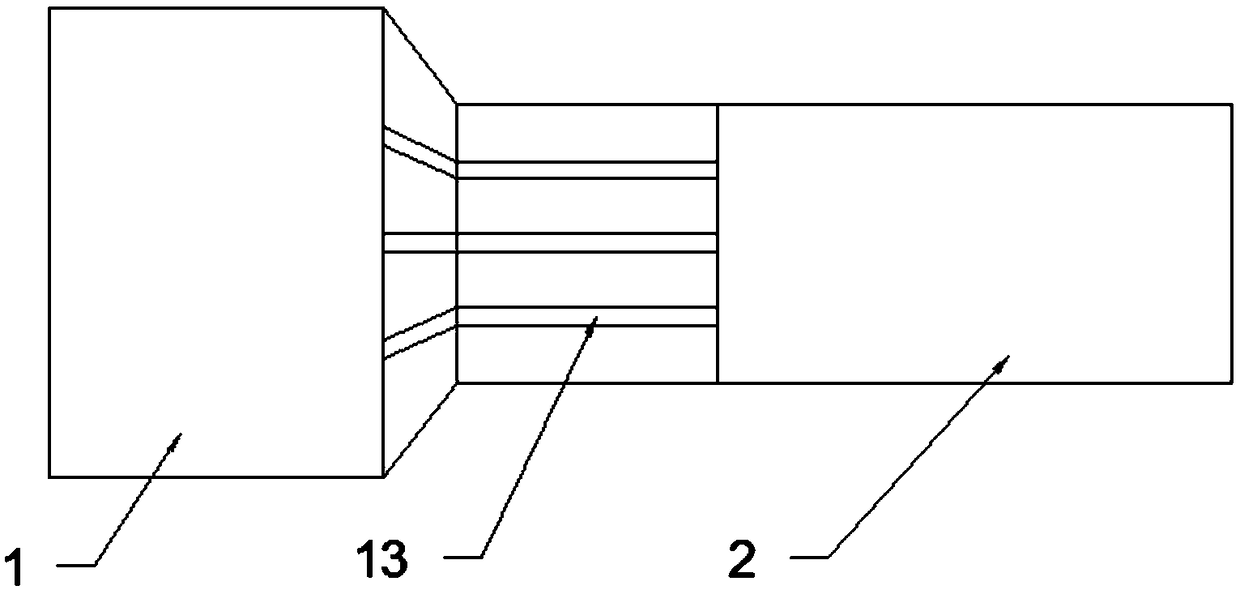

[0015] The reference signs in the accompanying drawings of the description include: guide plate 1, transmission pipe 2, support rod 3, base 4, fixed rod 5, conveyor belt 6, partition plate 7, hydraulic rod 8, pressure plate 9, tooth marks 10, endless belt 11 , roller 12, drainage plate 13.

[0016] The embodiment is basically as attached figure 1 , attached figure 2 And attached image 3 Shown:

[0017] A plastic bottle cap separation device, comprising a base 4, a feeding mechanism and a transmission mechanism, the base 4 is provided with a timing switch (not shown in the figure), the transmission mechanism is located on the base 4, the transmission mechanism includes a conveyor belt 6, the conveyor belt 6 It is electrically connected with the timing switch, and a fixed rod 5 is connected between the conveyor belt 6 and the base 4, and the conveyor belt 6 is in a horizontal sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com