Rotary feeder used for transferring of powder and granular materials

A granular material and rotary feeding technology, which is applied in the direction of rotary conveyor, conveyor, transportation and packaging, etc., can solve the problems of extremely serious environmental pollution, sending to low places, and large loss, so as to avoid dust pollution, The effect of reducing transportation loss and reducing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

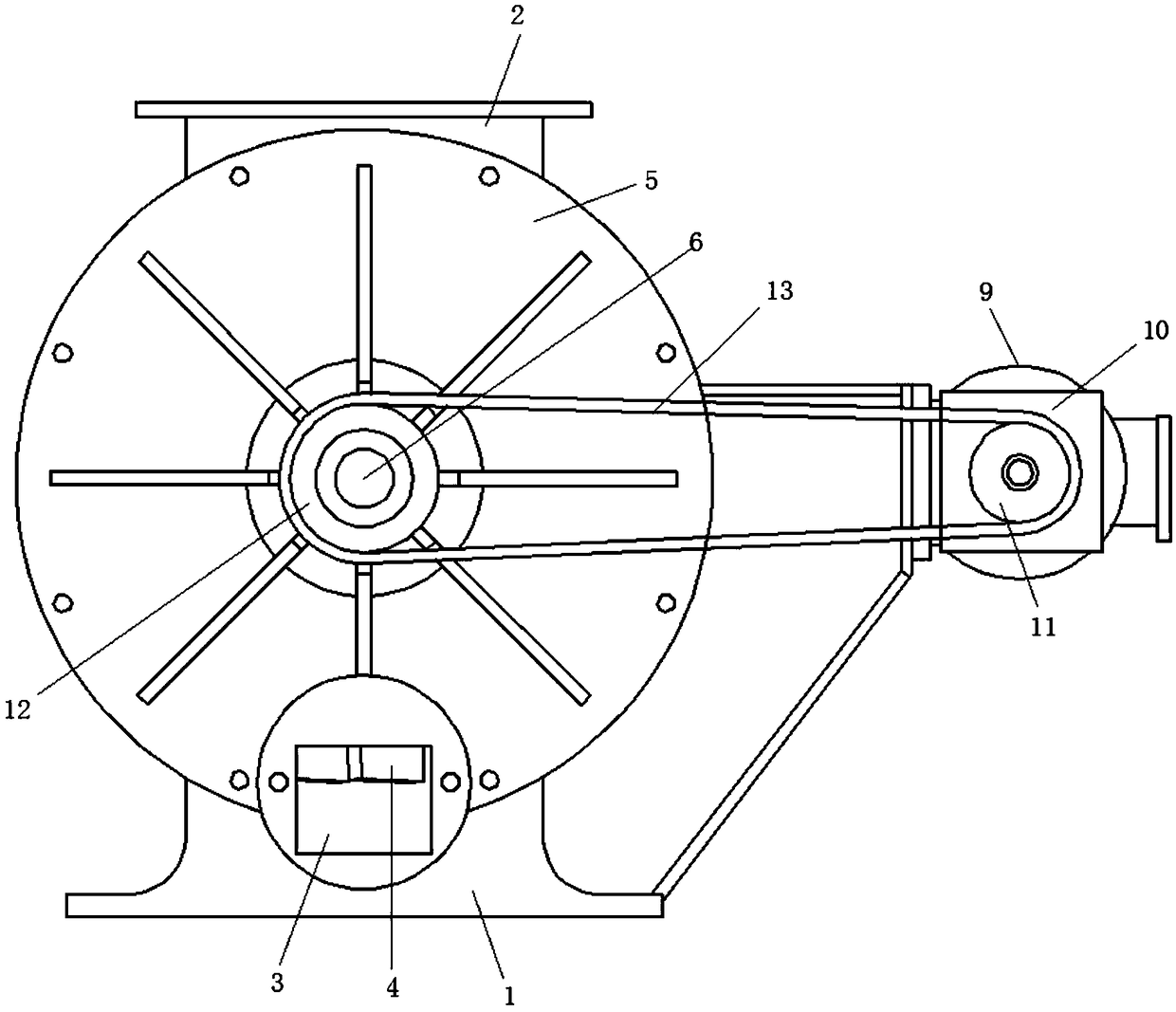

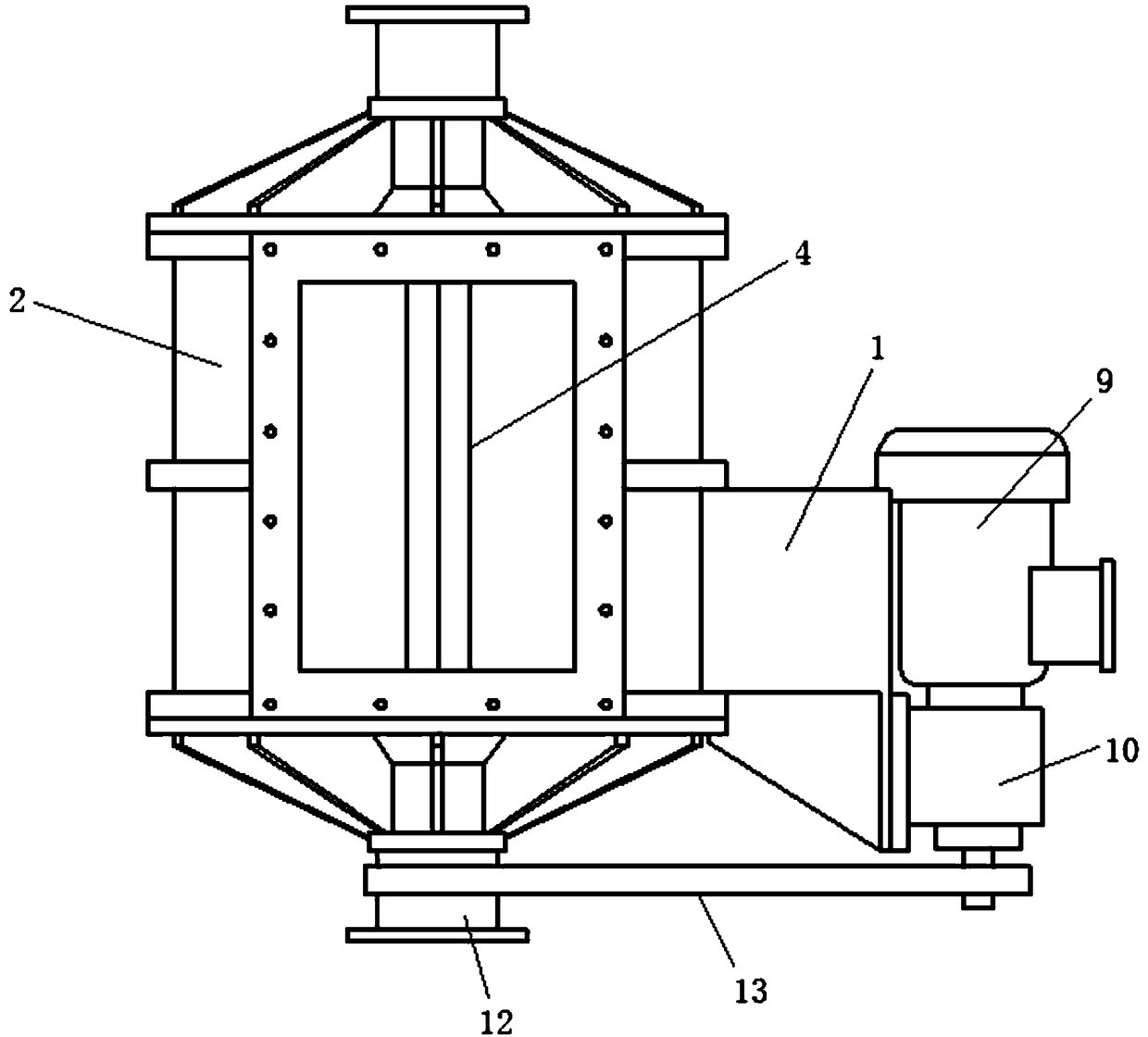

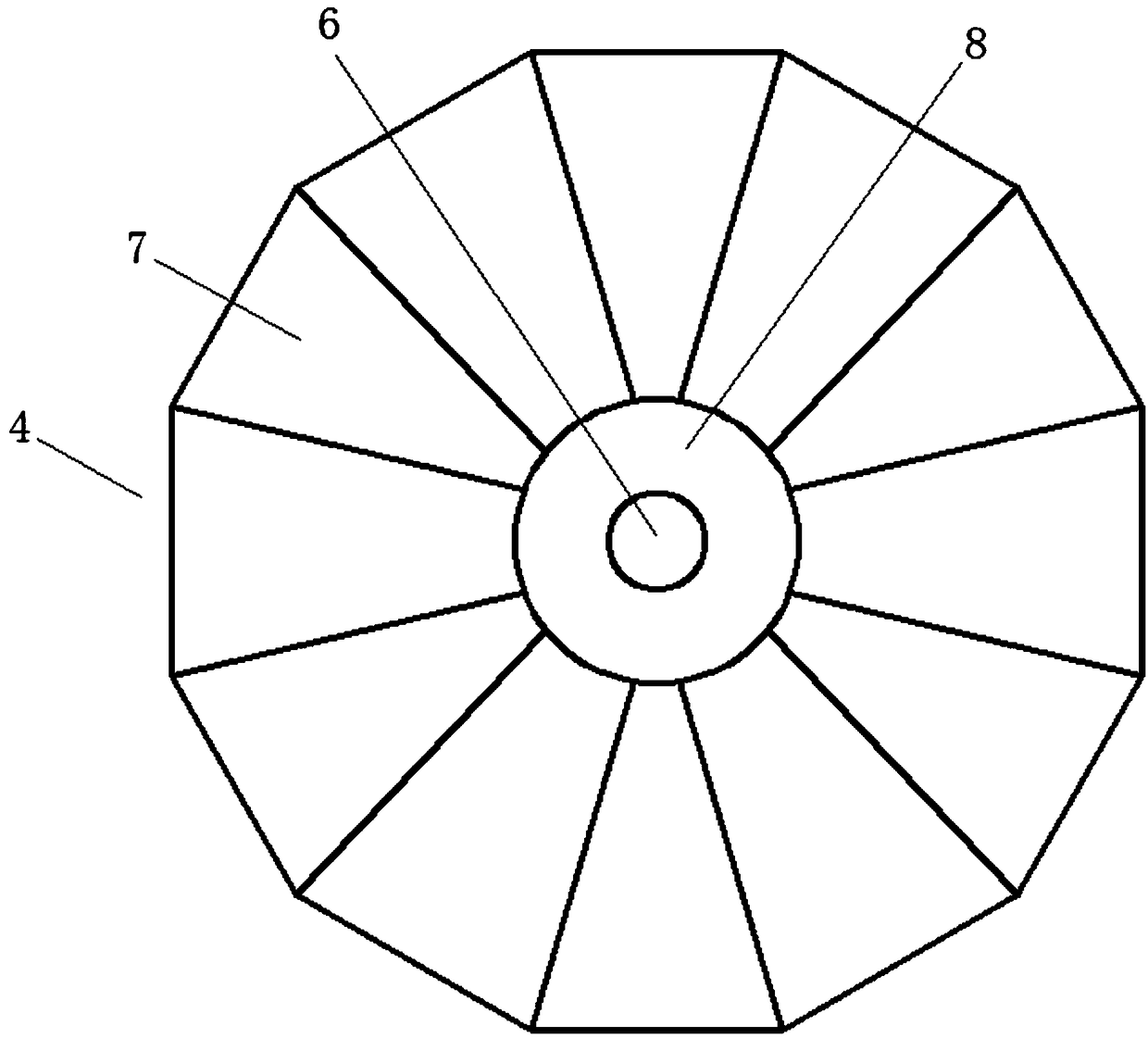

[0015] Attached below Figure 1-3 An embodiment of the present invention is described.

[0016] The rotary feeder used for the transfer of powder and granular materials has a base 1, a material transfer device is arranged above the base 1, and a feed hopper 2 located at the upper end of the material transfer device and an upper port of the rotary hopper 4 inside the material transfer device Corresponding positions, both sides of the lower end of the material transfer device are provided with a discharge port 3 and the discharge port 3 corresponds to the position of the lower port of the rotary hopper 4 inside the material transfer device, and a power drive device is installed on the outer wall of the upper end of the base 1 and The power drive device is connected with the rotary hopper 4 in the material transfer device, and drives the rotary hopper 4 to rotate to realize the rotary transfer of the material in the rotary hopper 4; specifically, the material transfer device incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com