Straight rodlike object non-pressure rotation delivering equipment and method

A technology of rotating transfer and straight rod, applied in the direction of conveyor objects, transportation and packaging, conveyors, etc., can solve the problems of not being very large, unable to meet the high-speed operation of the hood, affecting the normal and effective operation rate of the hood equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

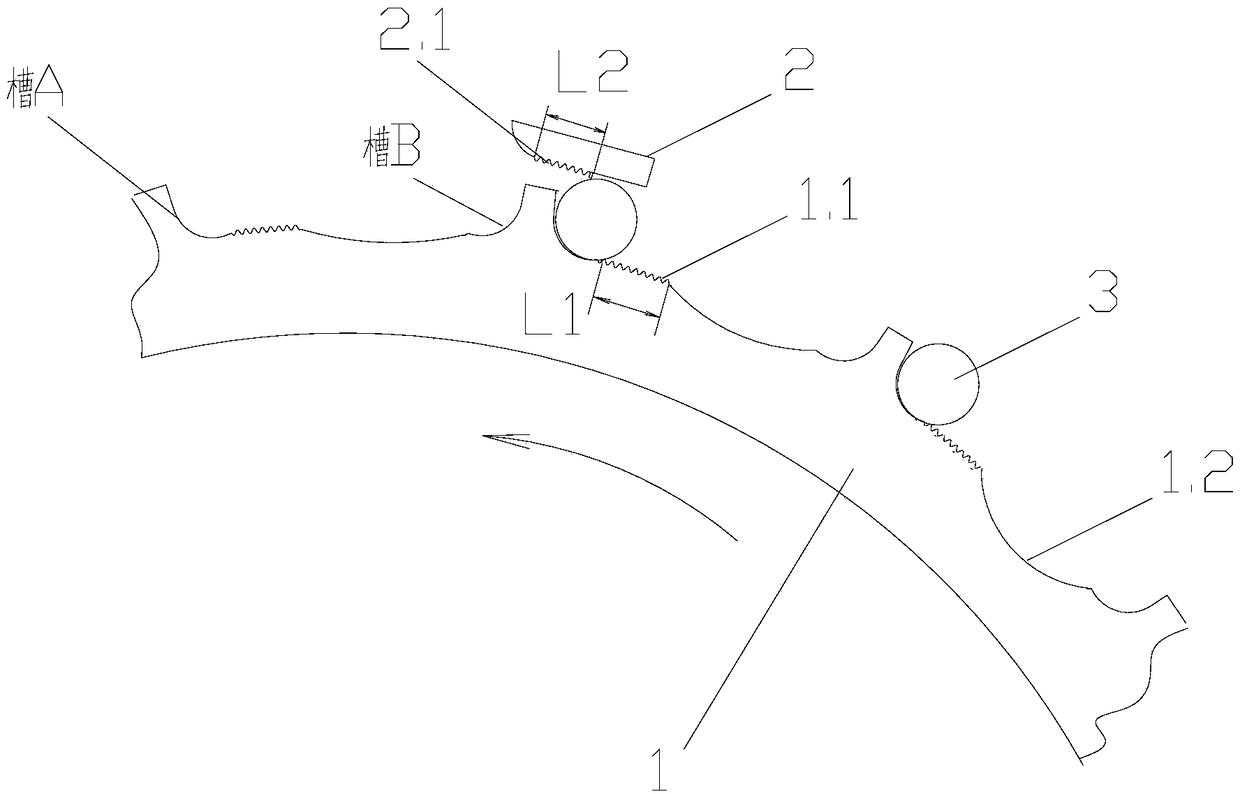

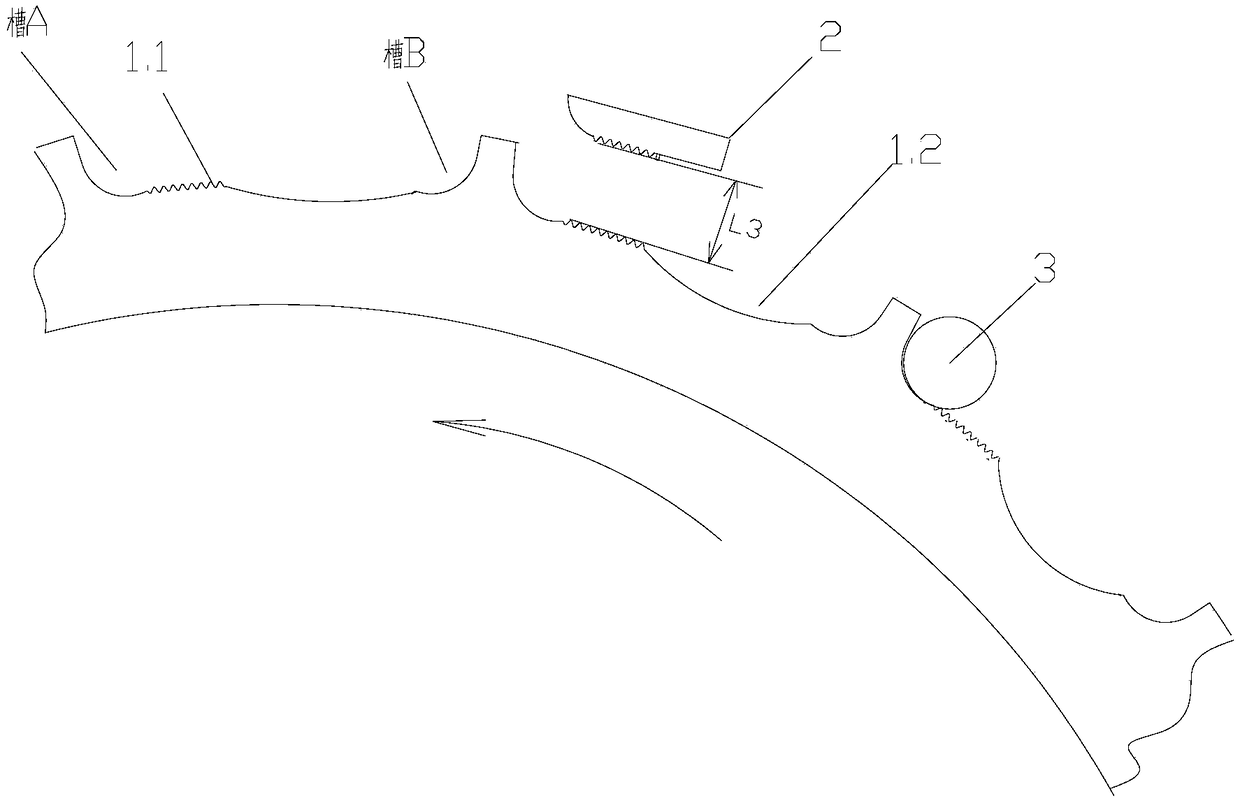

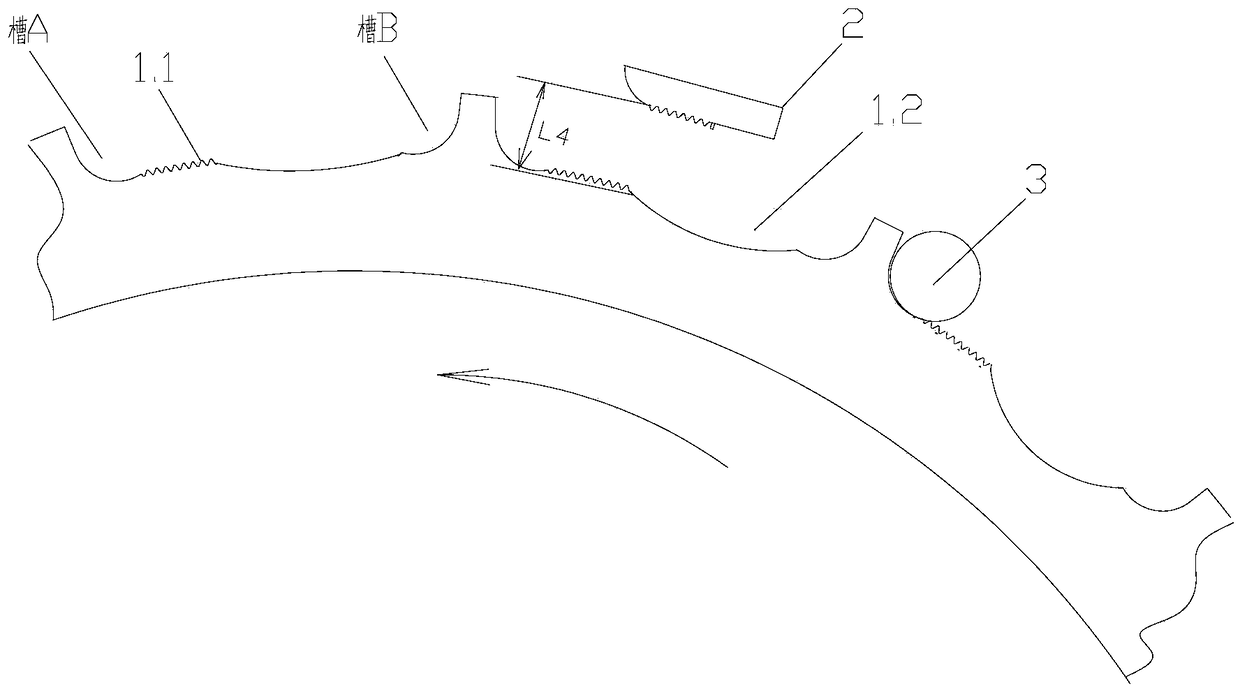

[0029] A pressureless rotary transmission device for straight rod-shaped objects, including an intermediate drum 1 supported on a frame to connect the input drum and the output drum, the outer circle of the intermediate drum 1 has at least two radial protrusions and Stem-shaped strips parallel to the drum axis. Both sides of the stem-shaped strips have suction holes connected to the negative pressure source. The surface of the drum between two adjacent stem-shaped strips is sequentially provided with groove A, rolling surface 1.1, concave surface 1.2 and Groove B, groove A and groove B are provided with negative pressure adsorption holes for absorbing the straight rod 3, the rolling surface 1.1 is a toothed surface protruding radially from the surface of the drum, and the concave surface 1.2 is a smooth concave surface; One side of the wheel 1 is provided with a washboard 2 distributed parallel to the stem-shaped strips. When the straight rod 3 is absorbed by the groove A of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com