Wear-resistant and corrosion-resistant cr/cralsin composite coating, its preparation method and application

A composite coating and corrosion-resistant technology, applied in the wear-resistant and corrosion-resistant Cr/CrAlSiN composite coating and its preparation, in the field of wear-resistant and corrosion-resistant coatings, can solve the problems of inability to meet the needs of the workpiece, material peeling, easy failure, etc. Achieve good application prospects, prevent coating failure and peeling, and improve the effect of bearing and anti-wear ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] Another aspect of the embodiments of the present invention provides a method for preparing a wear-resistant and corrosion-resistant Cr / CrAlSiN composite coating, which may include the following steps:

[0037] Perform ion nitriding treatment and / or ion etching treatment on the surface of the substrate;

[0038] And, sequentially depositing a Cr layer and a CrAlSiN layer on the surface of the substrate to form the composite coating.

[0039] In some preferred embodiments, the preparation method includes: performing surface cleaning treatment on the surface of the substrate, and then sequentially performing ion nitriding treatment and ion etching treatment on the clean substrate surface, which has the effect of purifying the surface and can remove the surface of the workpiece. Passive film and pollutants.

[0040] Further, the surface cleaning treatment includes: sequentially ultrasonically cleaning the surface of the substrate with a degreasing agent and more than one o...

Embodiment 1

[0071] Embodiment 1: with 304 stainless steel spheres as sample, the technique that forms Cr / CrAlSiN composite coating on its surface comprises the following steps:

[0072] (1) Sample pretreatment: In order to remove the oil on the surface of the sample, first put the sample in a degreasing agent (such as petroleum ether) and ultrasonically clean it for 30 minutes, then put it in acetone and ultrasonically clean it for 10 minutes, and then ultrasonically clean it in absolute ethanol 10min, finally take it out and dry it with nitrogen gas, and carry out ion nitriding treatment.

[0073] Preferably, the above-mentioned ion nitriding treatment specifically includes: placing the cleaned substrate in the chamber of the coating equipment, feeding nitrogen with a flow rate of 1000 sccm, controlling the working pressure at 8Pa, applying a -800V negative bias to the substrate, and the temperature The temperature is controlled at 450°C, and the nitriding treatment time is 2 hours. The...

Embodiment 2

[0081] Embodiment 2: a ball valve made of 316 stainless steel is used as a substrate, and the process of forming a Cr / CrAlSiN composite coating on its surface comprises the following steps:

[0082] (1) Sample pretreatment: In order to remove the oil on the surface of the sample, first put the sample in a degreasing agent (such as petroleum ether) and ultrasonically clean it for 30 minutes, then put it in acetone and ultrasonically clean it for 10 minutes, and then ultrasonically clean it in absolute ethanol 10min, finally take it out and dry it with nitrogen gas, and carry out ion nitriding treatment.

[0083] As a preference, the above-mentioned ion nitriding treatment specifically includes: placing the cleaned substrate in the vacuum chamber of the coating equipment, feeding in a nitrogen gas flow rate of 1200 sccm, controlling the working pressure at 9Pa, applying a -1000V negative bias to the substrate, and controlling the temperature At 500°C, the nitriding treatment tim...

PUM

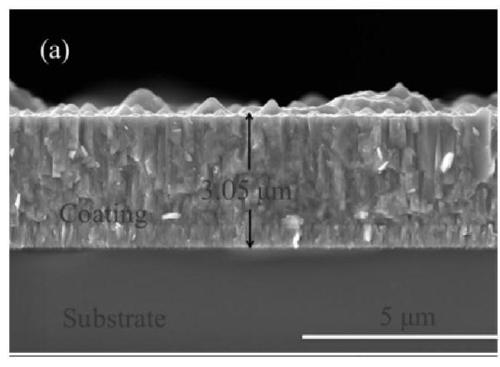

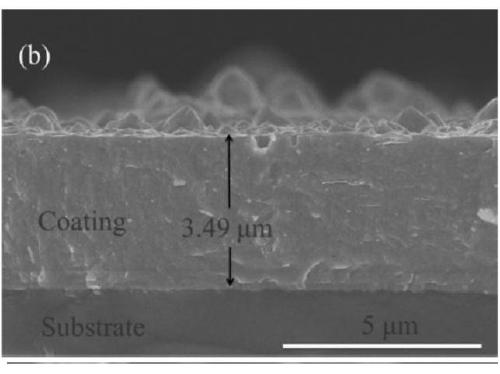

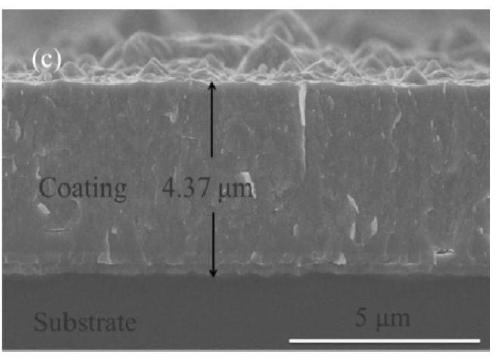

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com