A kind of graphene compound for lubricating oil additive and its preparation method and application

A graphene and compound technology, applied in the field of oil-soluble graphene compounds and their preparation, can solve the problems of "increased agglomeration" and achieve the effects of reduced friction coefficient, mild reaction conditions, and excellent oil solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

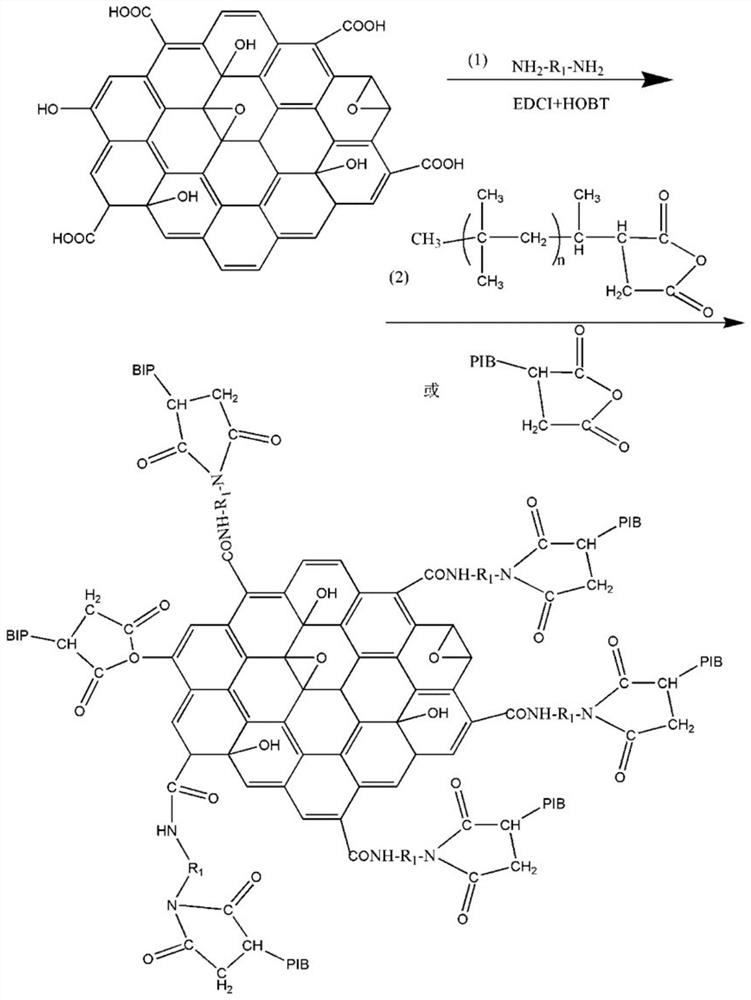

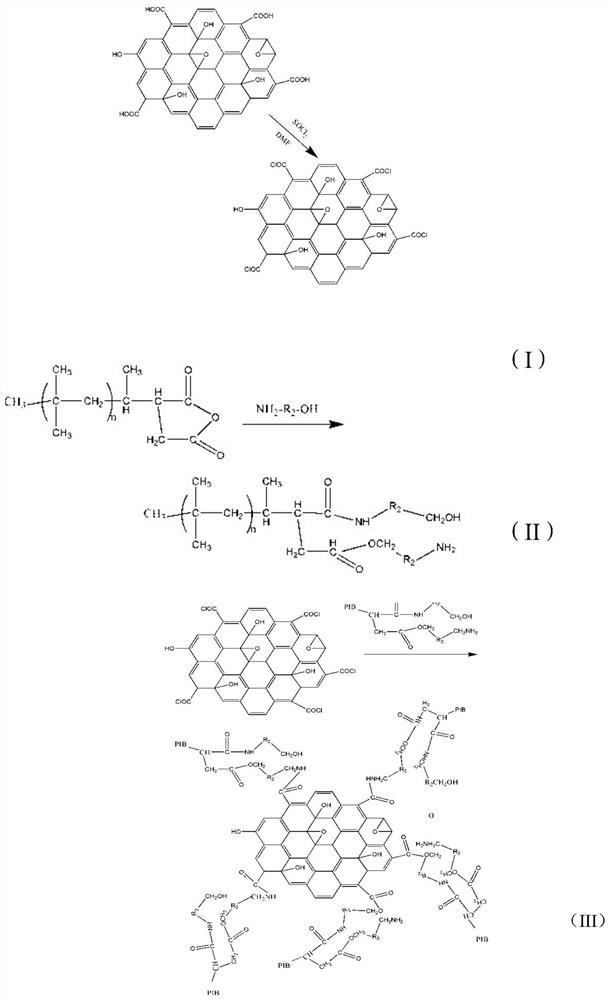

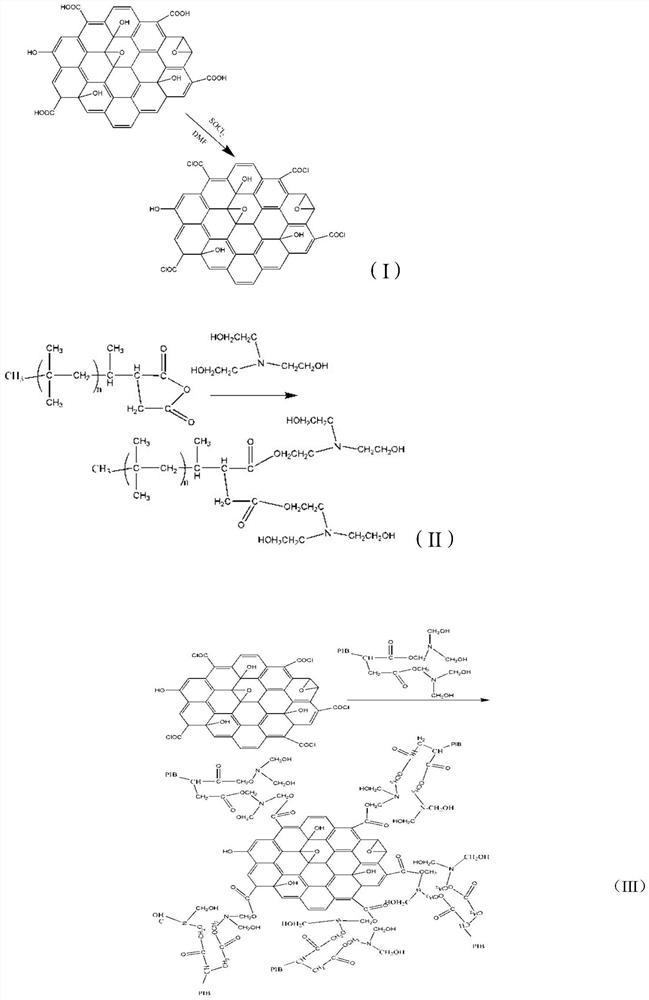

Method used

Image

Examples

Embodiment 1

[0059] The present embodiment provides a graphene compound for lubricating oil additive. It is polyisobutylene succinic anhydride with a molecular weight of 3000.

[0060] The present embodiment also provides a preparation method of the above-mentioned graphene compound, which is specifically as follows:

[0061] (1) Add 200mL of DMF and 1g of graphene oxide to a 500ml three-necked bottle, seal it well, and sonicate for half an hour; under temperature control, add 1-hydroxybenzotriazole (3.1g) and 1-(3- DMF solution of dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride (2.5g) and methanol solution of 1g PAMAM dendrimer (G1); under nitrogen protection, magnetic stirring at room temperature for 48 hours , transferred to a single-necked bottle to remove DMF by rotary evaporation, then filtered, rinsed with methanol to remove 1-hydroxybenzotriazole and 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride , and dried in a vacuum drying oven at 80° C. for 12 h to obtain...

Embodiment 2

[0065] The present embodiment provides a graphene compound for lubricating oil additive. It is polyisobutylene succinic anhydride with a molecular weight of 1000.

[0066] The present embodiment also provides a preparation method of the above-mentioned graphene compound, which is specifically as follows:

[0067] (1) Add 200mL of DMF and 1g of graphene oxide to a 500ml three-necked bottle, seal it well, and sonicate for half an hour; under temperature control, add 1-hydroxybenzotriazole (3.09g) and 1-(3- DMF solution of dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride (2.5g) and methanol solution of 2g PAMAM dendrimer (G2); under nitrogen protection, magnetic stirring at room temperature for 48 hours , transferred to a single-necked bottle to remove DMF by rotary evaporation, then filtered, rinsed with methanol to remove 1-hydroxybenzotriazole and 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride , and dried in a vacuum drying oven at 80° C. for 12 h to obtai...

Embodiment 3

[0071] The present embodiment provides a graphene compound for lubricating oil additive. It is polyisobutylene succinic anhydride with a molecular weight of 3000.

[0072] The present embodiment also provides a preparation method of the above-mentioned graphene compound, which is specifically as follows:

[0073] (1) Add 200mL of DMF and 1g of graphene oxide to a 500ml three-necked bottle, seal it well, and sonicate for half an hour; control the temperature and add dropwise 1-hydroxybenzotriazole (2.1g) and 1-(3- DMF solution of dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride (1.42g) and methanol solution of 1.5g PAMAM dendrimer (G3); under nitrogen protection, magnetic stirring at room temperature for reaction 48 hours, transferred to a single-necked flask to remove DMF by rotary evaporation, then filtered, rinsed with methanol to remove 1-hydroxybenzotriazole and 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride The salt was dried in a vacuum drying oven a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com