Graphene compound for lubricating oil additive, preparation method and application thereof

A kind of compound and graphene technology, applied in the direction of lubricating composition, petroleum industry, etc., can solve the problem of "increased agglomeration"

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

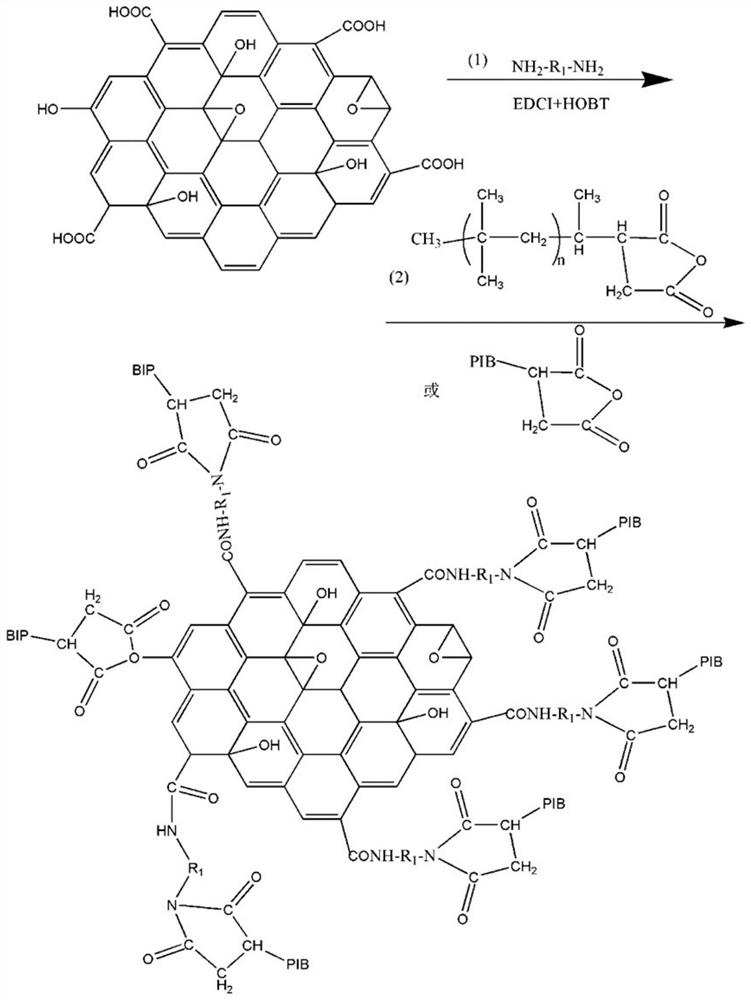

Method used

Image

Examples

Embodiment 1

[0059] The present embodiment provides a kind of graphene compound that is used for lubricating oil additive, and its structural formula is: Γ~N~R, wherein, Γ is 5 layers of graphene oxide, and N is the PAMAM dendrimer polymer G1 of 1 generation, R It is polyisobutylene succinic anhydride with a molecular weight of 3000.

[0060] The present embodiment also provides the preparation method of above-mentioned graphene compound, specifically as follows:

[0061] (1) Add 200mL of DMF and 1g of graphene oxide into a 500ml three-neck flask, seal it well, and ultrasonicate for half an hour; control the temperature below 10°C and dropwise add 1-hydroxybenzotriazole (3.1g) and 1-(3- DMF solution of dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride (2.5g) and methanol solution of 1g PAMAM dendrimer (G1); after dripping, under nitrogen protection conditions, magnetically stirred and reacted at room temperature for 48 hours , transferred to a one-necked bottle and rotary evaporated ...

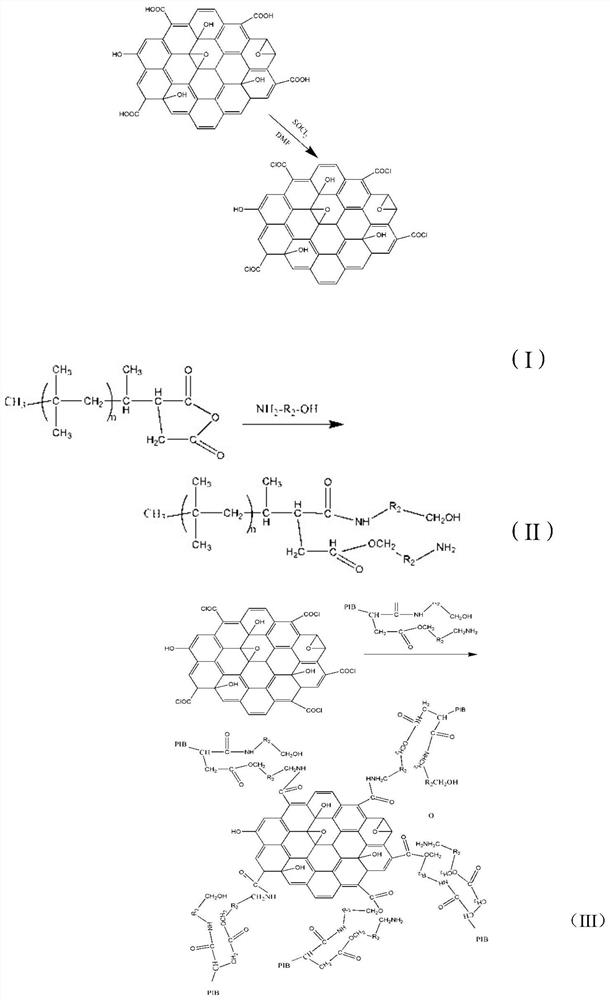

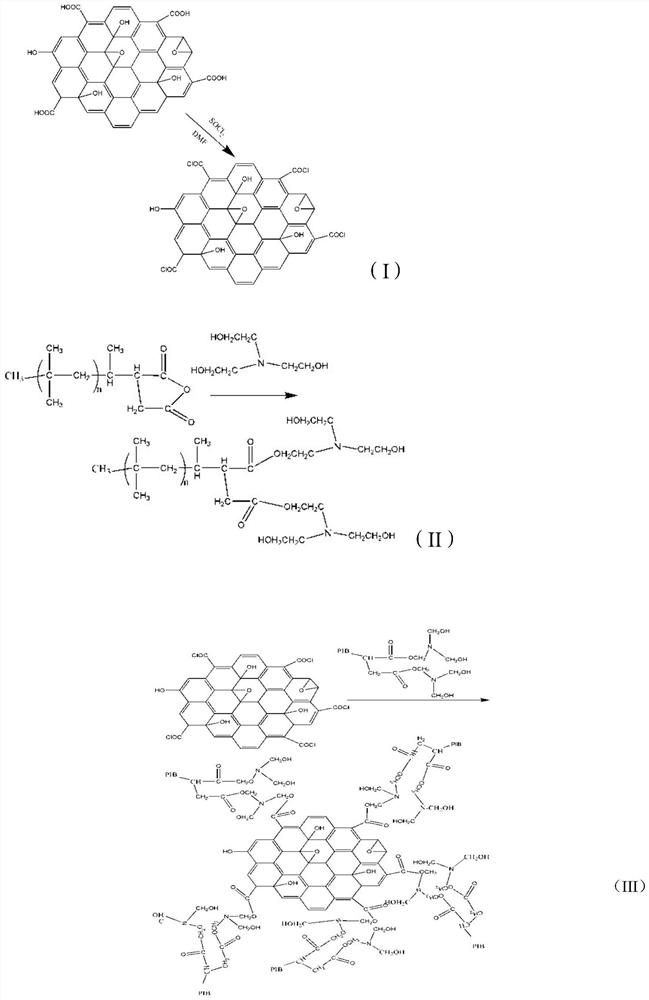

Embodiment 2

[0065] The present embodiment provides a kind of graphene compound that is used for lubricating oil additive, and its structural formula is: Γ~N~R, wherein, Γ is 7 layers of graphene oxide, N is the PAMAM dendrimer polymer G2 of 2 generations, R It is polyisobutylene succinic anhydride with a molecular weight of 1000.

[0066] The present embodiment also provides the preparation method of above-mentioned graphene compound, specifically as follows:

[0067] (1) Add 200mL of DMF and 1g of graphene oxide into a 500ml three-necked flask, seal it well, and ultrasonicate for half an hour; control the temperature below 10°C and add dropwise 1-hydroxybenzotriazole (3.09g) and 1-(3- DMF solution of dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride (2.5g) and methanol solution of 2g PAMAM dendrimer (G2); dropwise under nitrogen protection conditions, magnetic stirring normal temperature reaction for 48 hours , transferred to a one-necked bottle and rotary evaporated to remove DMF,...

Embodiment 3

[0071] The present embodiment provides a kind of graphene compound that is used for lubricating oil additive, and its structural formula is: Γ~N~R, wherein, Γ is 6 layers of graphene oxide, and N is the PAMAM dendrimer polymer G3 of 3 generations, R It is polyisobutylene succinic anhydride with a molecular weight of 3000.

[0072] The present embodiment also provides the preparation method of above-mentioned graphene compound, specifically as follows:

[0073] (1) Add 200mL of DMF and 1g of graphene oxide into a 500ml three-necked bottle, seal it well, and ultrasonicate for half an hour; control the temperature below 10°C and add 1-hydroxybenzotriazole (2.1g) and 1-(3- DMF solution of dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride (1.42g) and methanol solution of 1.5g PAMAM dendrimer (G3); dropwise under nitrogen protection conditions, magnetic stirring normal temperature reaction 48 hours, transferred to a single-necked bottle to remove DMF by rotary evaporation, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com