Composite coating on the surface of a valve seal and its preparation method

A valve sealing, composite coating technology, applied in the direction of coating, chemical instruments and methods, metal material coating process, etc., can solve low friction, long life and corrosion resistance, abnormal coating peeling fatigue wear, coating The problems of large layer brittleness and other problems can prevent coating failure and peeling, the preparation method is simple and feasible, and the corrosion resistance performance is improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] In this embodiment, the base body is a valve 304 stainless steel sphere or a butterfly valve 316 stainless steel disc. Clean and degrease multiple substrate samples, and then use multi-arc ion plating technology to deposit coatings on the surface of each substrate respectively. During the deposition process of each sample, the ion plating uses Cr targets, and the current of the Cr targets is kept at 50 ~100A, negative bias voltage of -20~-50V is applied on the substrate, and the heating temperature is controlled to be kept at 400℃~450℃ during the deposition process. The specific deposition conditions of different samples are as follows.

[0036] (1) Sample 1: The argon gas flow rate was maintained at 100 sccm, the nitrogen gas flow rate was 25 sccm, and the deposition time was 4 hours to obtain coating 1;

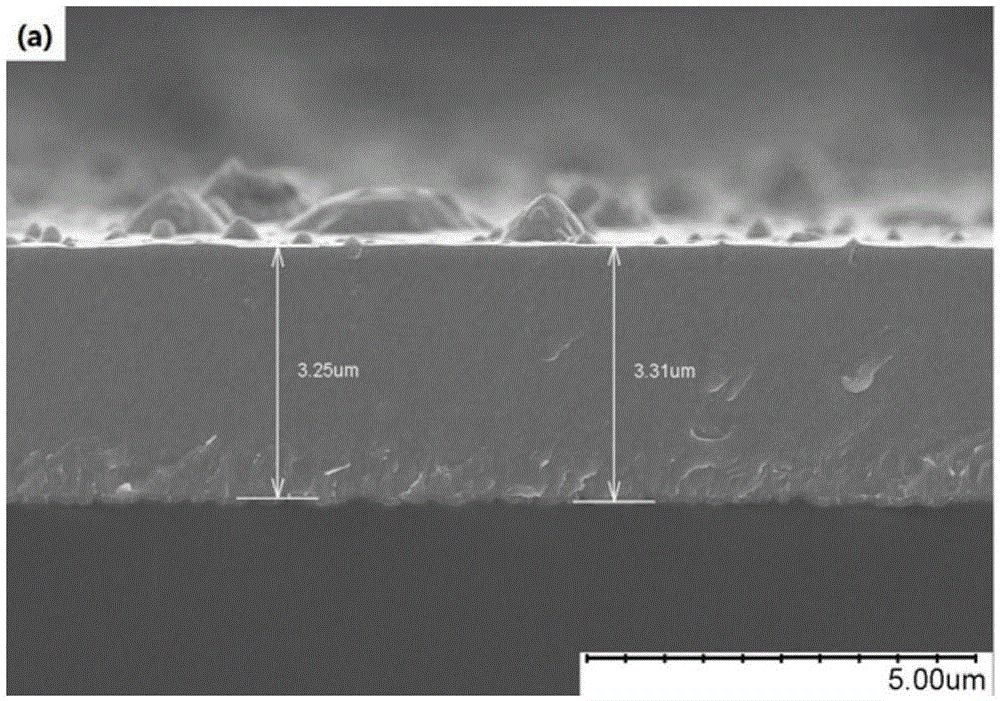

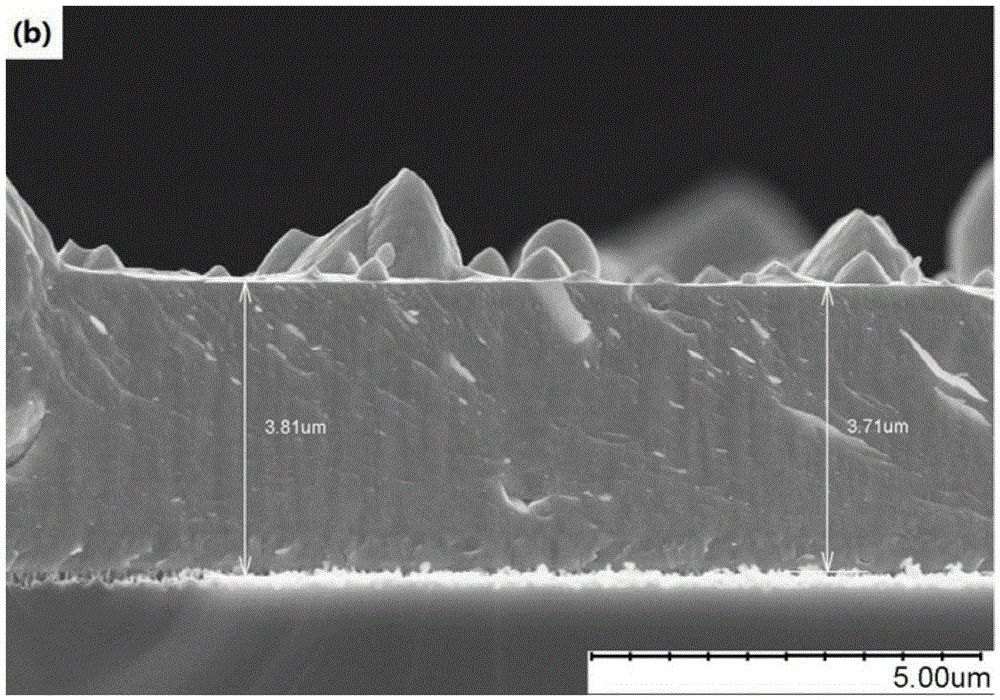

[0037] The cross-sectional appearance of the coating 1 is as follows: figure 2 As shown, it can be seen that the planar thickness of the coating is about 3.3um, an...

Embodiment 2

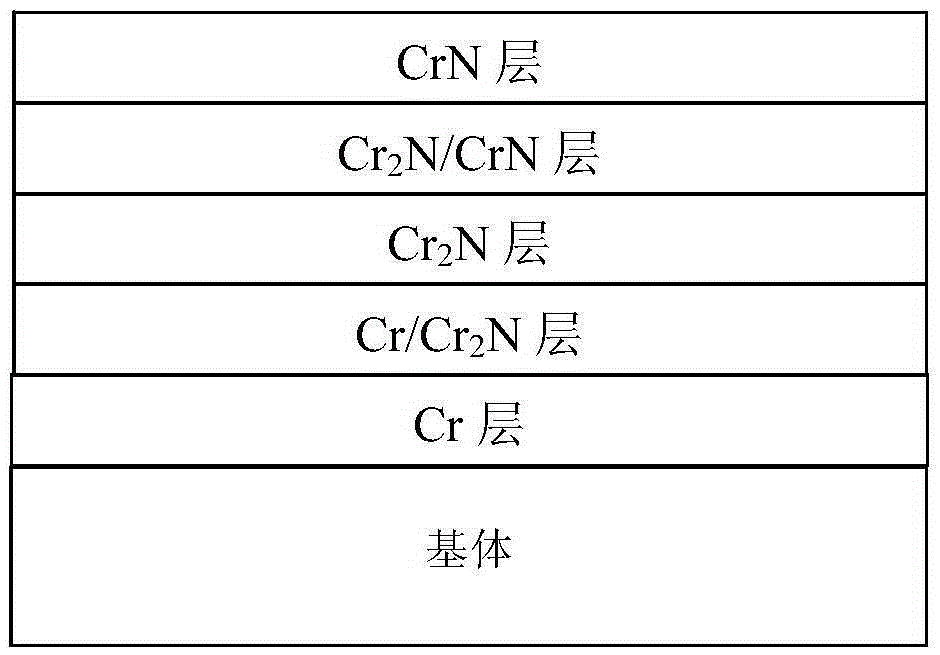

[0052] In this embodiment, the base part is a valve 304 stainless steel sphere, and the composite coating on the base surface is composed of Cr layers stacked on the base surface from bottom to top, composed of Cr and Cr 2 Cr / Cr formed by N mixing 2 N layer, Cr 2 N layer, made of Cr 2 Cr mixed with N and CrN 2 N / CrN layer, and CrN layer. Wherein, the thickness of the composite coating is 30 μm˜50 μm. Among them, the thickness of Cr layer is 0.3um~1um; Cr / Cr 2 The thickness of N layer is 5um~10um; Cr 2 The thickness of the N / CrN layer is , and the thickness of the CrN layer is 5um˜8um.

[0053] Using ion nitriding technology and multi-arc ion plating technology to prepare the above composite coating, the specific preparation process is as follows:

[0054] 1. Sandblasting the 304 stainless steel sphere, the process parameters of the sandblasting treatment are: pressure 0.3MPa, sand particle size 320#, sandblasting distance 100mm; then, ultrasonically clean the 304 stainl...

Embodiment 3

[0070] In this embodiment, the base part is a butterfly valve 316 stainless steel plate, and the composite coating on the surface of the base is composed of Cr layers stacked on the surface of the base from bottom to top, composed of Cr and Cr 2 Cr / Cr formed by N mixing 2 N layer, Cr 2 N layer, made of Cr 2 Cr mixed with N and CrN 2 N / CrN layer, and CrN layer. Wherein, the thickness of the composite coating is 30 μm˜50 μm. Among them, the thickness of Cr layer is 0.3um~1um; Cr / Cr 2 The thickness of N layer is 5um~10um; Cr 2 The thickness of the N / CrN layer is , and the thickness of the CrN layer is 5um˜8um.

[0071] Adopt ion nitriding technology and multi-arc ion plating technology to prepare above-mentioned composite coating, step 1 and step 2 in the specific preparation process are respectively identical with step 1 and step 2 in embodiment 2, and step 3 and step 4 are as follows:

[0072] 3. Introduce argon gas and high-purity nitrogen gas (99.95% purity) to deposit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com