A kind of wear-resistant and corrosion-resistant cralsin composite coating and preparation method thereof

A composite coating and corrosion-resistant technology, which is applied in coatings, metal material coating processes, solid-state diffusion coatings, etc., can solve the problems of abnormal spalling, fatigue wear, low friction, long life and corrosion resistance of coatings, and easy Corrosion and peeling problems, to achieve good application prospects, prevent coating failure and peeling, and improve the effect of bearing and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] A preparation method of a wear-resistant and corrosion-resistant CrAlSiN composite coating, comprising the following steps:

[0039] Step 1. Cleaning, degreasing, and surface activation treatment on the surface of the substrate; the specific surface activation treatment is: place the substrate in the vacuum chamber of the coating equipment, preheat the substrate to 400°C~450°C after vacuuming, and use argon plasma to Activation by bombarding the surface of the substrate with a negative bias voltage applied; the specific process is: the vacuum chamber is evacuated to (3~6)×10 -3 Pa, preheat the substrate to 400°C~450°C, pass in the working argon gas of 100~350sccm, start the bias power supply, and bombard the substrate with a bias voltage of -900~-1200V for 10 minutes to activate the surface of the substrate;

[0040] Step 2. Place the substrate treated in step 1 in the vacuum chamber of the coating equipment, select Cr and AlSi targets, target current is 50~100A, apply ...

Embodiment 1

[0049] The ball valve made of 304 stainless steel is used as the substrate, including the following steps:

[0050] Step 1. Cleaning, degreasing, and surface activation treatment on the surface of the substrate; the specific surface activation treatment is: place the substrate in the vacuum chamber of the coating equipment, preheat the substrate to 400°C~450°C after vacuuming, and use argon plasma to Activation by bombardment on a negatively biased substrate surface;

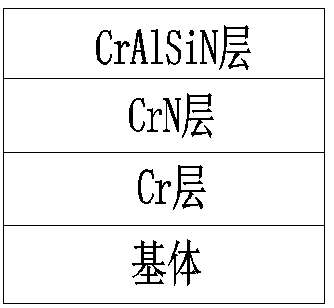

[0051] Step 2. Place the substrate treated in step 1 in the vacuum chamber of the coating equipment, select Cr and AlSi targets, target current is 50~100A, apply negative bias voltage of -20~-50V to the workpiece, and control the heating temperature to 400°C At ~450°C, argon and nitrogen are introduced, and the composition of Cr layer, CrN layer and CrAlSiN layer is sequentially deposited on the surface of the substrate by controlling the flow rate of argon gas, nitrogen gas flow and deposition time, as follows:...

Embodiment 2

[0057] The butterfly valve made of 316 stainless steel is used as the substrate, including the following steps:

[0058] Step 1. Cleaning, degreasing, and surface activation treatment on the surface of the substrate; the specific surface activation treatment is: place the substrate in the vacuum chamber of the coating equipment, preheat the substrate to 400°C~450°C after vacuuming, and use argon plasma to Bombard the surface of the substrate with a negative bias to activate it; then perform ion nitriding treatment on the substrate: place the substrate in the vacuum chamber of the coating equipment, feed nitrogen with a flow rate of 1000~1200sccm, and control the working air pressure at 8~10Pa. -800~-1000V negative bias, temperature controlled at 450~500℃, nitriding treatment time is 2~4 hours;

[0059] Step 2. Place the substrate treated in step 1 in the vacuum chamber of the coating equipment, select Cr and AlSi targets, target current is 50~100A, apply negative bias voltage ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com