Device for producing spunbonds from endless filaments

A filament and equipment technology, which can be used in felting equipment, filament/thread forming, textile and paper making, etc., and can solve problems such as unsatisfactory filament deposition quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

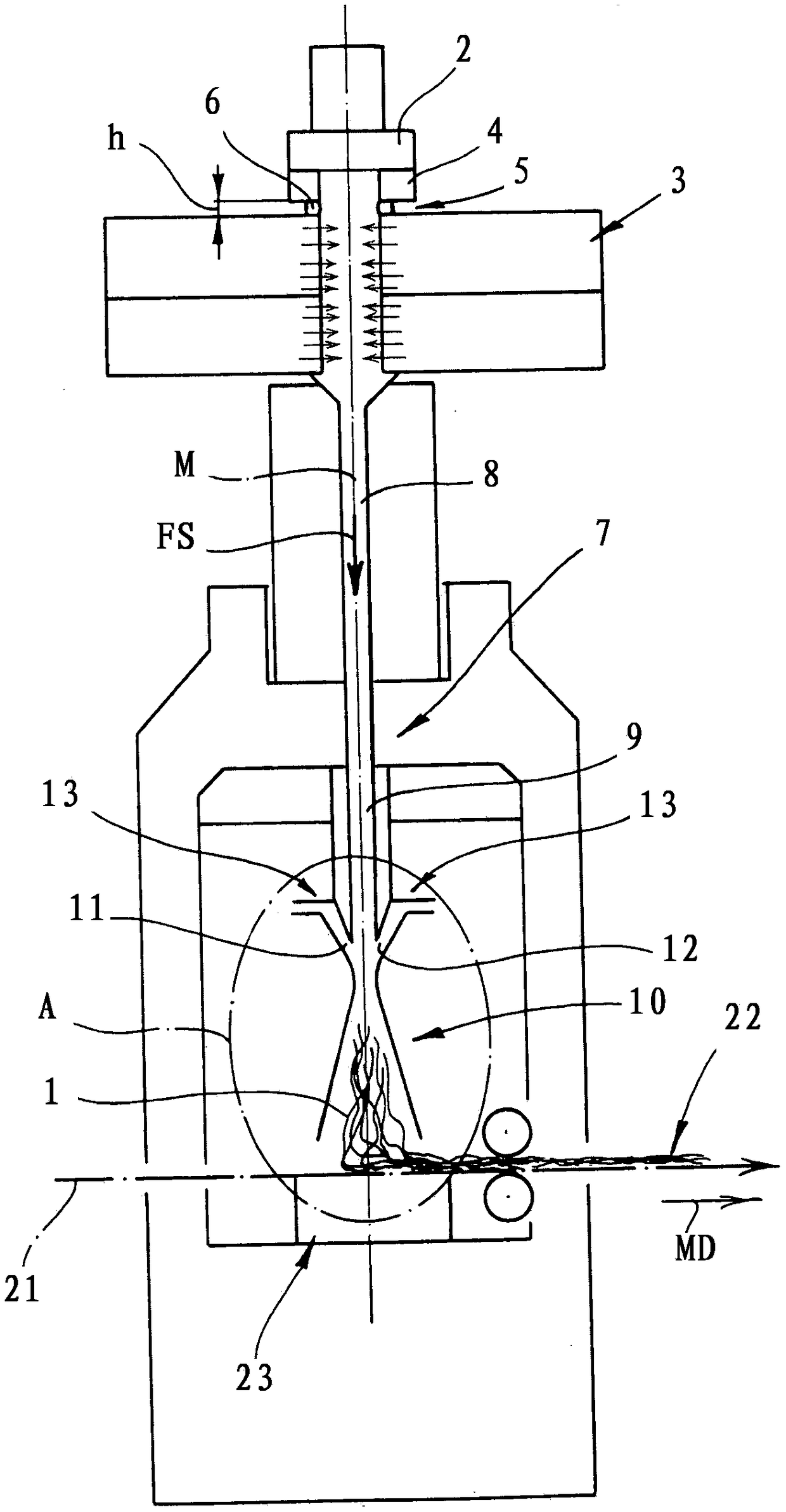

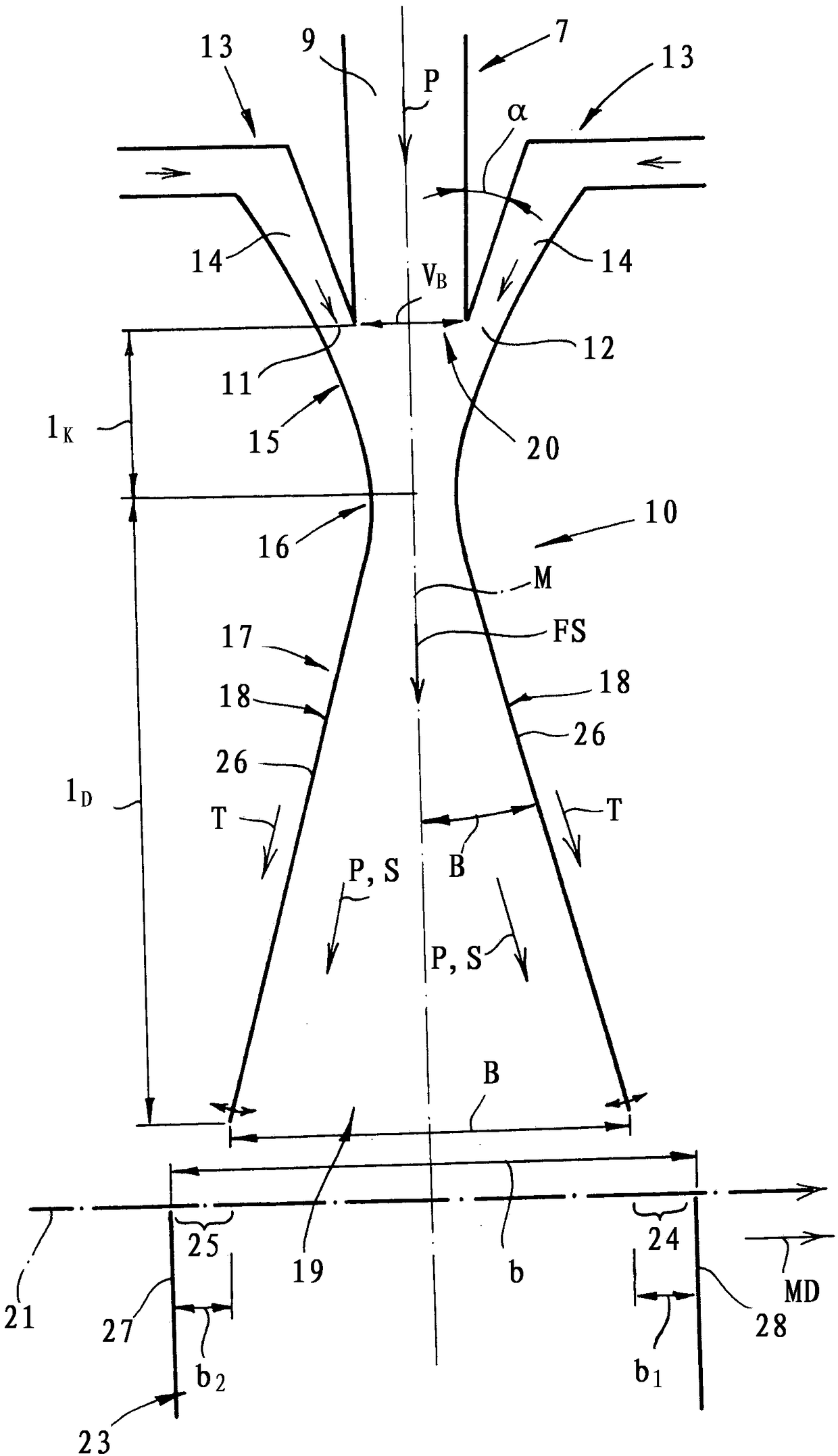

[0027] The figure shows an apparatus according to the invention for producing a spunbond fabric of filaments 1 , in particular made of filaments 1 of thermoplastic material. The apparatus comprises a spinneret 2 for spinning a filament 1 and a cooling device 3 for cooling the filament. According to a particularly preferred embodiment of the invention, the monomer extraction device 4 is arranged between the spinneret 2 and the cooling device 3 . By means of such a monomer extraction device 4 disturbing gases generated during the spinning process can be removed from the device. These may be, for example, monomers, oligomers or decomposition products and the like. A gap 5 is formed between the monomer extraction device 4 and the cooling device 3, which generally extends around the entire filament forming space or filament flow space. According to a very preferred embodiment and in the exemplary embodiment according to the figure (see especially figure 1 ), at least one deforma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com