washing machine

A technology for washing machines and washing tanks, applied in the field of washing machines, which can solve the problems of increased manufacturing costs, entry of lint, complicated structures, etc., and achieve the effect of a simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

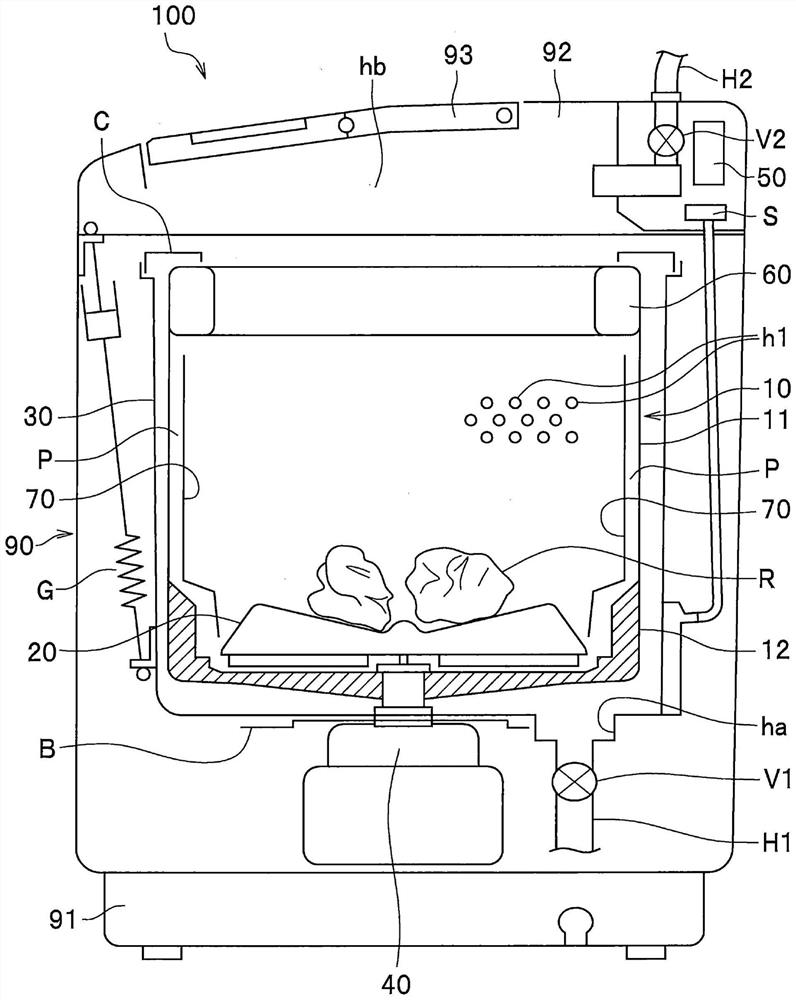

[0023] Hereinafter, as an example, the washing machine 100 (so-called fully automatic washing machine: refer to figure 1 )Be explained.

[0024] "Implementation"

[0025] figure 1 It is a schematic diagram showing the internal structure of washing machine 100 according to the embodiment.

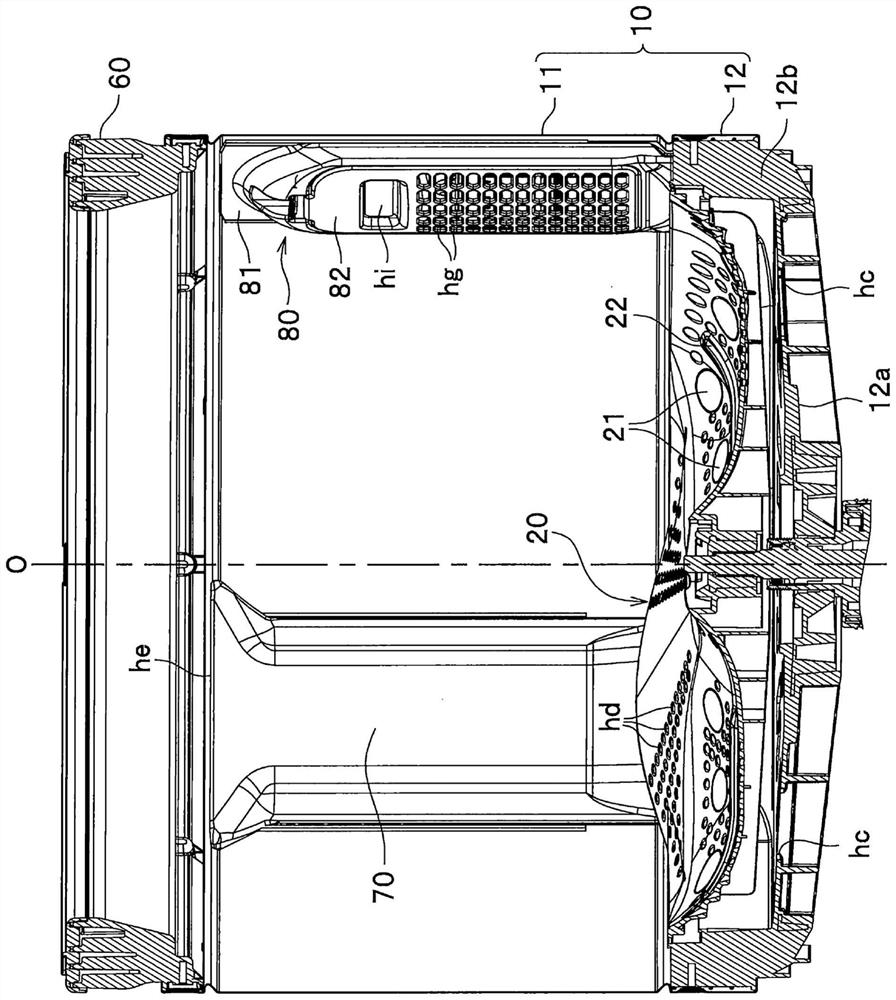

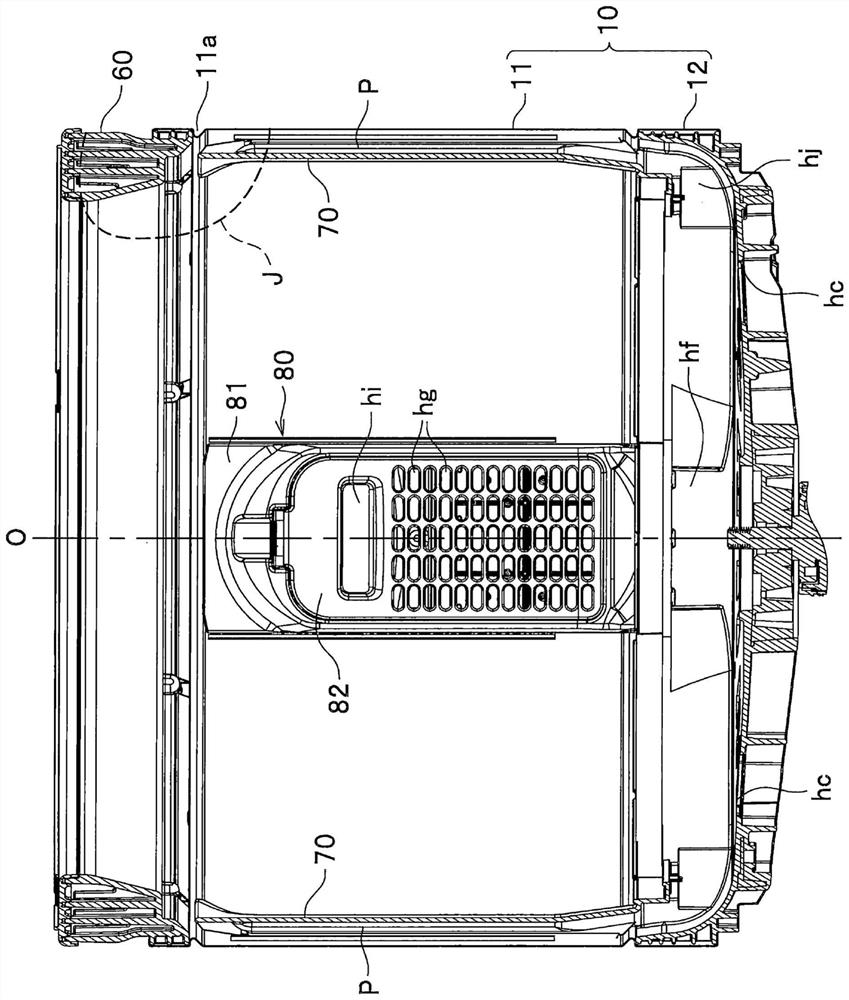

[0026] figure 1 The washing machine 100 shown is equipment for washing clothes, etc., and mainly includes a washing tank 10, a stirring blade 20, an outer tank 30, a driving device 40, a control unit 50, a balance ring 60 (fluid balancer), a circulation flow path member 70, 80, and outer frame 90. also, figure 1 In, another circulation flow path member 80 is not shown (refer to Figure 3A ).

[0027] The washing tub 10 accommodates the laundry R and has a bottomed cylindrical shape. The washing tub 10 includes a cylindrical main body plate 11 (surrounding wall of the washing tub 10 ), and a bottom plate 12 closing the lower portion of the main body plate 11 . The main body plate 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com