Heat exchanger and exhaust heat recovery device with the heat exchanger

A technology for heat exchangers and exhaust gas, which is applied in the direction of exhaust devices, heat exchangers, exhaust gas treatment, etc., can solve the problems of large quantities and difficulty in miniaturization, and achieve the effect of reducing space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

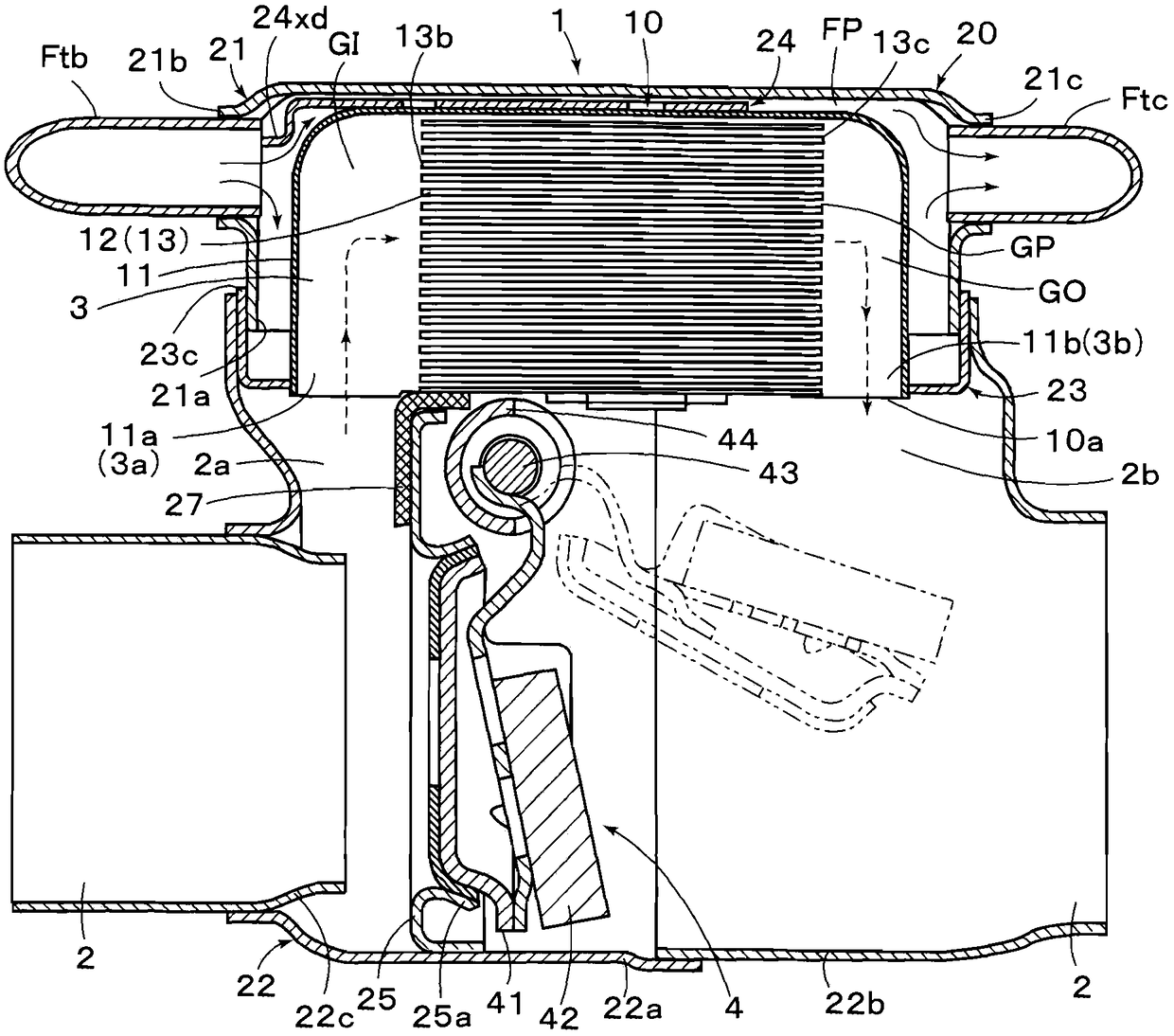

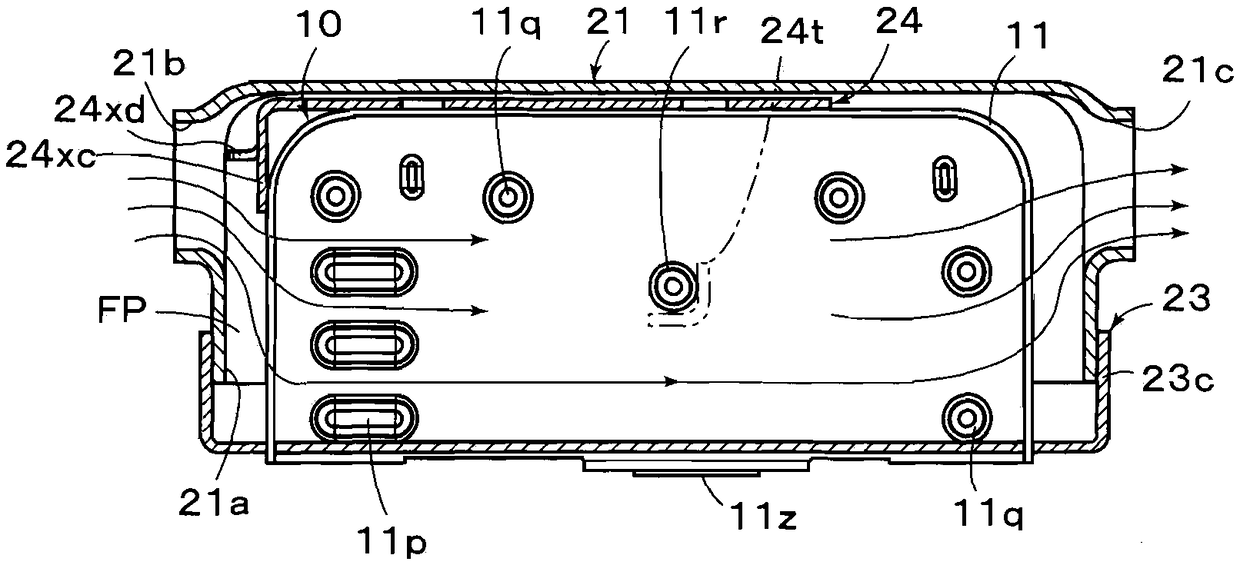

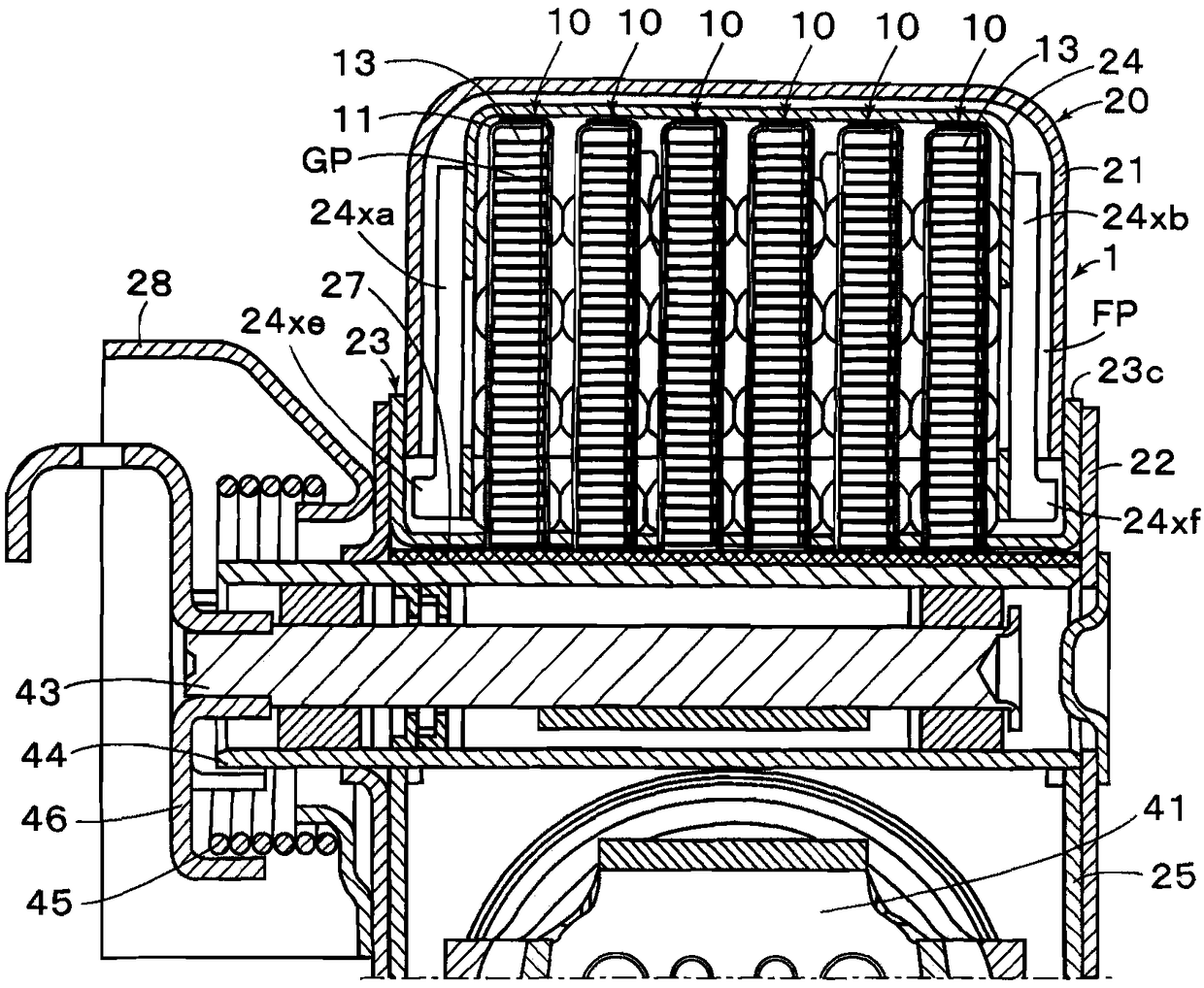

[0074] Preferred embodiments of the present invention will be described below with reference to the drawings. Figure 1 to Figure 3 It is a diagram showing an exhaust heat recovery device including a heat exchanger 1 according to an embodiment of the present invention, and includes a main exhaust flow path 2 for introducing exhaust gas from an internal combustion engine (not shown), and from the main exhaust flow path 2, a detour flow path 3 that branches off and merges with the main exhaust flow path 2, and a heat exchanger 1 that performs heat exchange between exhaust gas passing through the detour flow path 3 and a cooling medium to recover exhaust heat. In the present embodiment, the casing 20 of the exhaust heat recovery device is formed of an upper casing 21 arranged above the main exhaust flow path 2 (in a state mounted on a vehicle) and a lower casing 22 joined thereto. It has a frame shape and is separated in a liquid-tight manner by a sealing member 23 . In addition...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com