Pressure sensor

A pressure sensor, pressure surface technology, applied in the direction of measuring fluid pressure, instruments, measuring fluid pressure through electromagnetic components, etc., can solve problems such as reduced reliability of measured pressure and diaphragm bending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

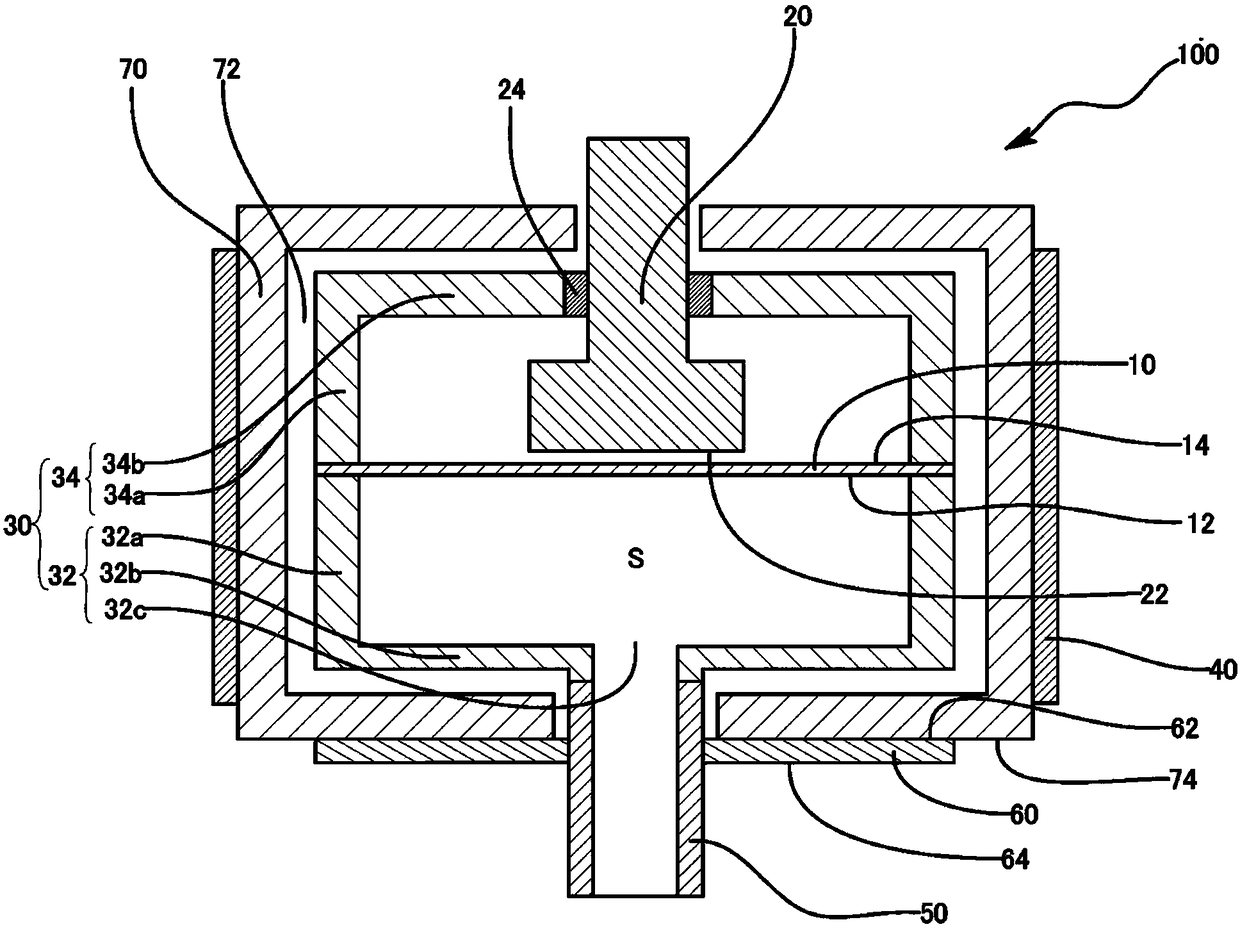

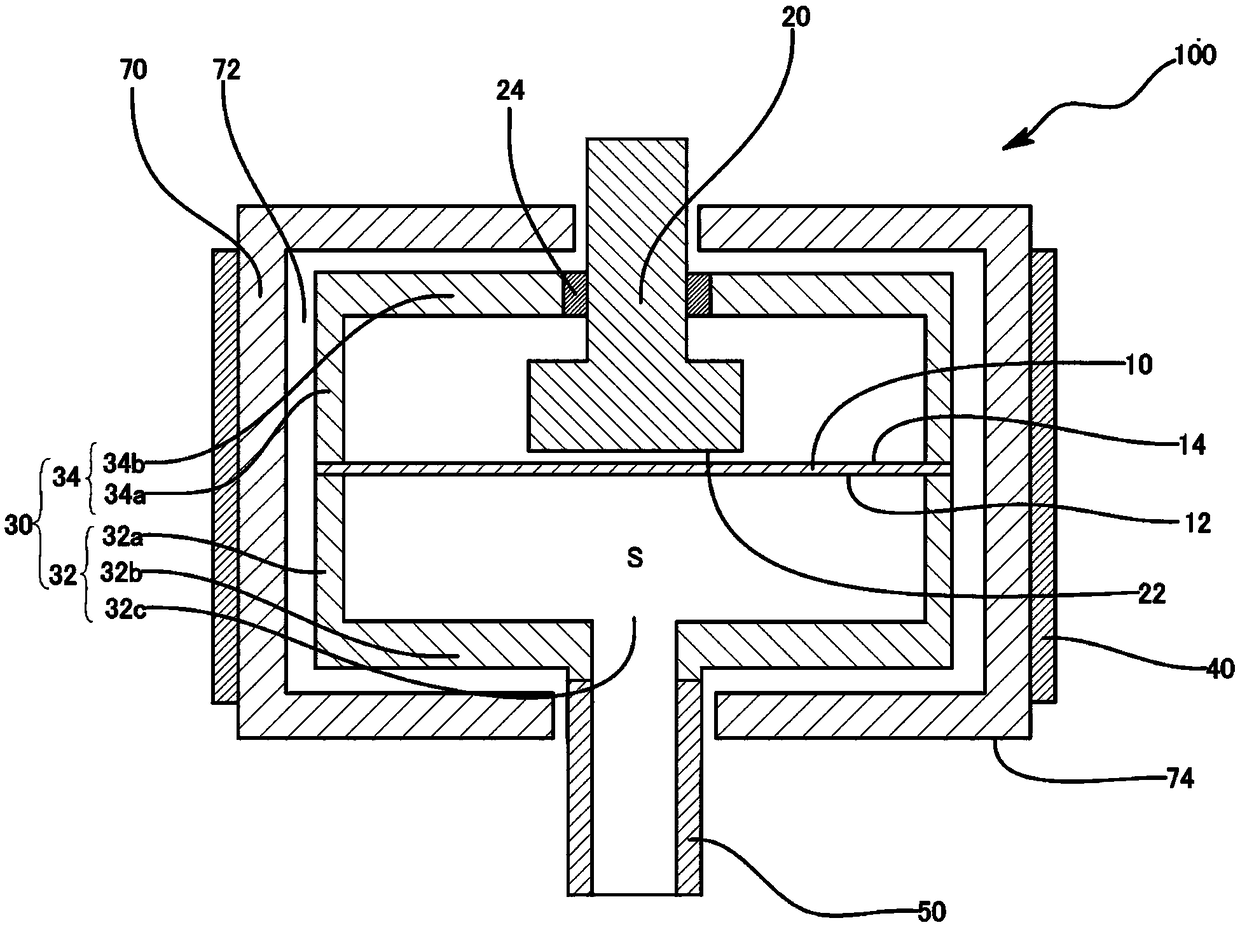

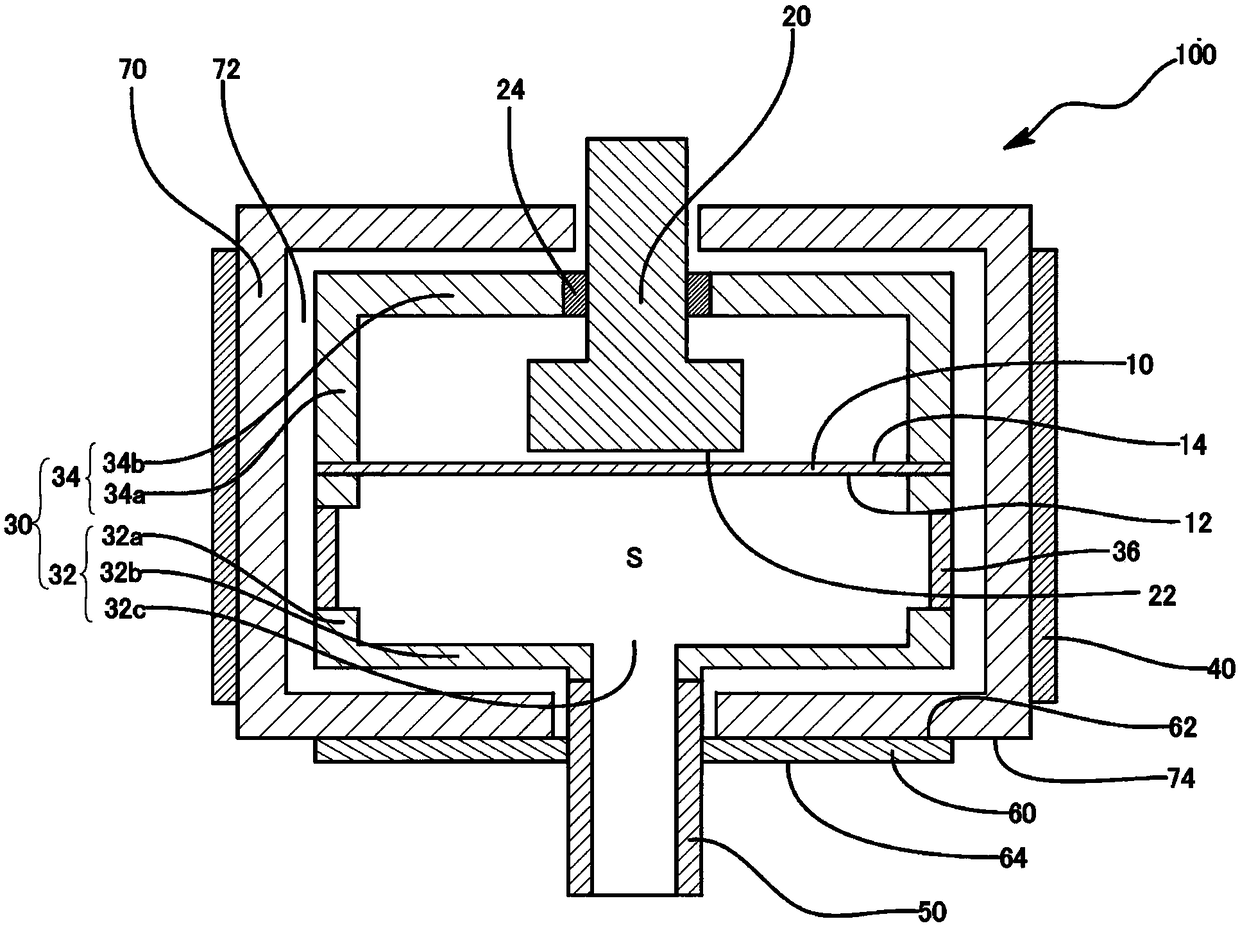

[0059] Hereinafter, an embodiment of the pressure sensor of the present invention will be described with reference to the drawings. However, the pressure sensor described below is merely an embodiment for embodying the technical idea of the present invention, and the present invention is not limited to the following description unless otherwise specified. In addition, the contents described in one embodiment can also be applied in other embodiments. In addition, dimensions, positional relationships, and the like of members shown in the drawings are sometimes exaggerated for clarity of description.

[0060] The pressure sensor 100 of the present embodiment is an absolute pressure measuring capacitive diaphragm vacuum gauge equivalent to a total pressure vacuum gauge, and detects the amount of change in capacitance between the diaphragm 10 and the fixed electrode (electrode body) 20 that is displaced by pressure, and converts it to The amount of change is converted into press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com