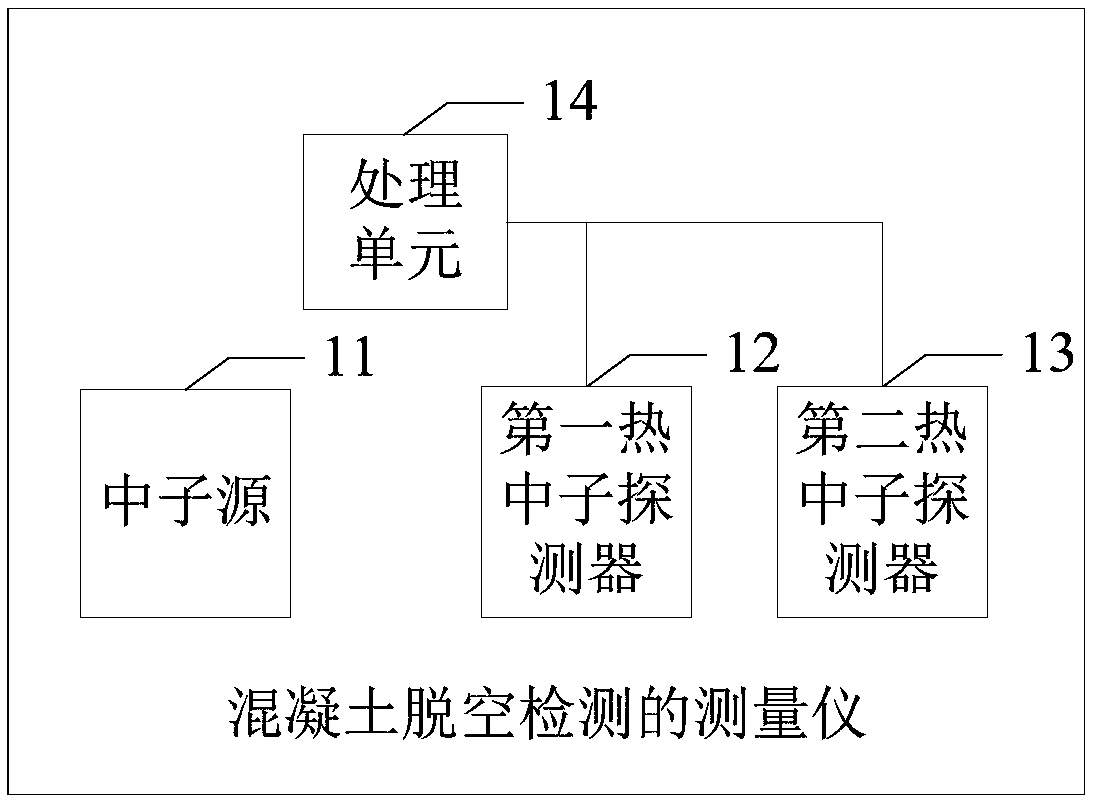

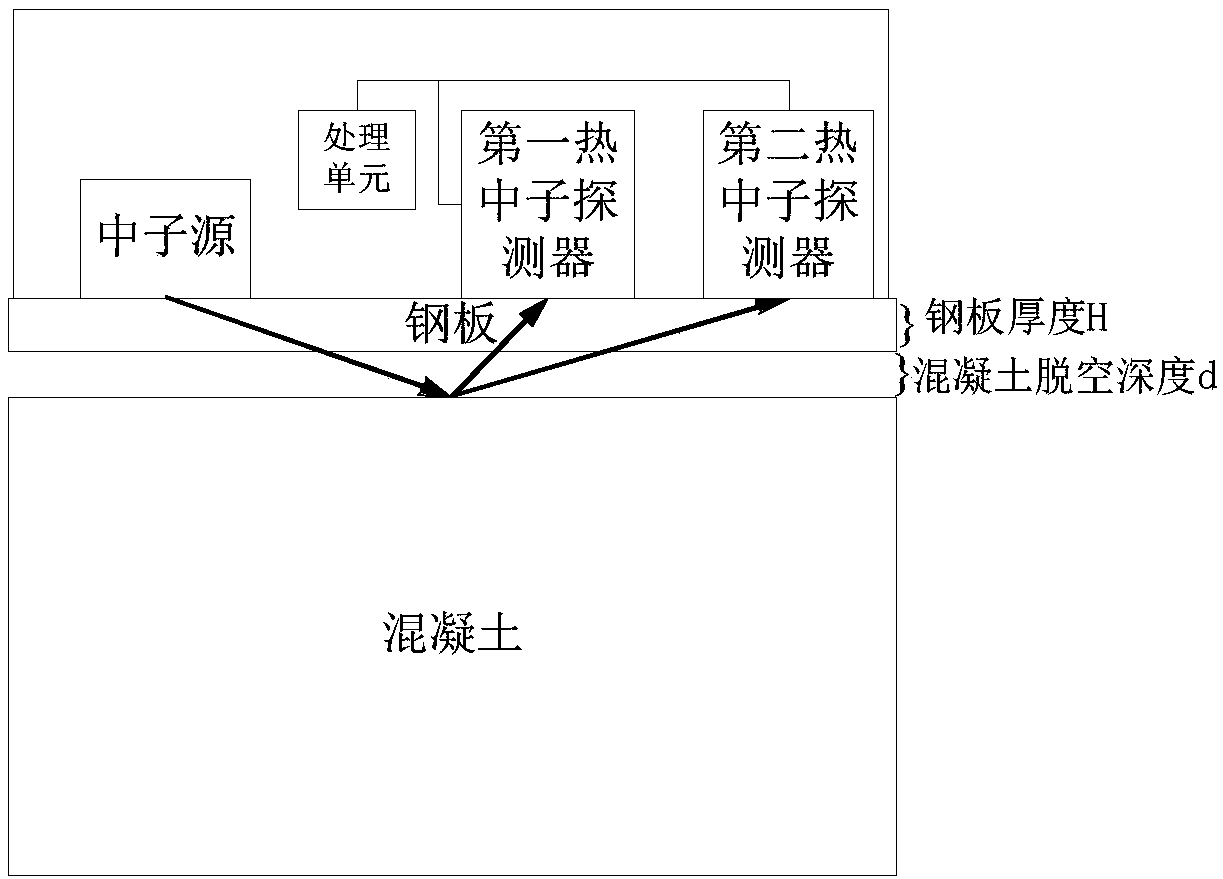

Measuring instrument for concrete void detection

A concrete and measuring instrument technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of low efficiency, cumbersome and inconvenient operating procedures, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 5

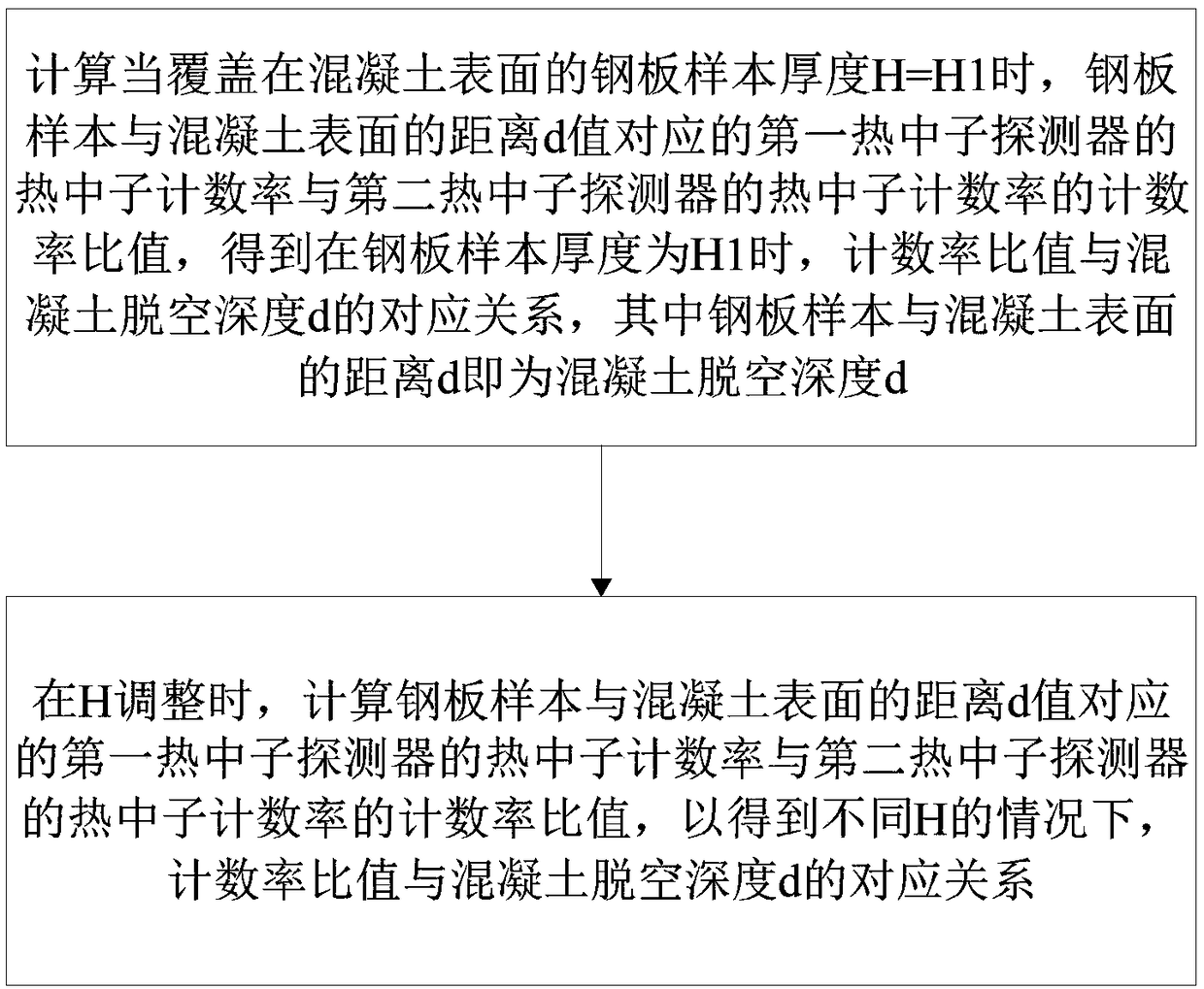

[0079] As a specific implementation method of screening out the required first thermal neutron detector and second thermal neutron detector from preset multiple thermal neutron detectors, such as Figure 5 As shown, Embodiment 5 of the present invention includes:

[0080] S501. The processing unit reads thermal neutron count rates respectively corresponding to multiple thermal neutron detectors.

[0081] S502. The processing unit combines the multiple thermal neutron detectors in pairs, and calculates the count rate ratio of each combination.

[0082] Wherein, assuming that the number of thermal neutron detectors is I, the number of combinations obtained by pairwise combination of I thermal neutron detectors is C(I, 2)=I! / [(I-2)! ×2! ].

[0083] S503. The processing unit calculates the difference between the count rate ratio of each combination and its corresponding standard ratio threshold, and uses the thermal neutron detector in the combination with the largest absolut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com