A high-power low-concentration gas engine and its gas supply method

A low-concentration gas and engine technology, which is applied in the direction of engine components, combustion engines, machines/engines, etc., can solve problems such as low utilization efficiency, difficult ignition, and difficult ignition, so as to prevent the influence of moisture and ensure the concentration of combustible gas. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

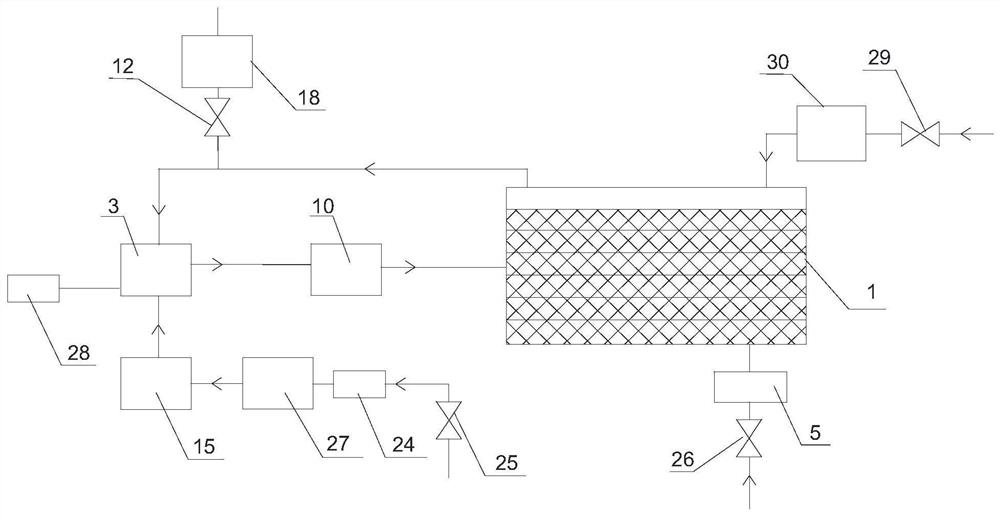

[0043] Embodiment one: if figure 1 As shown, a high-power low-concentration gas engine includes a main combustion chamber 1 and a pre-chamber combustion chamber 5, and also includes a preheating zone 3, a first valve 12, a second valve 25, a third valve 26 and a first booster Compressor 27;

[0044] The preheating zone 3 communicates with the main combustion chamber 1, the preheating zone 3 is used for preheating low-concentration gas, and transfers the preheated low-concentration gas to the main combustion chamber 1 for combustion;

[0045] The flue gas outlet of the main combustion chamber 1 is connected in parallel with the preheating zone 3 and the first valve 12 through a pipeline, which is used to provide high-temperature flue gas to the preheating zone 3, and opens the first valve 12 to discharge the preheating zone 3 and the main Flue gas from combustion chamber 1;

[0046] The pre-chamber combustor 5 has an intake passage 19, and the intake passage 19 is connected t...

Embodiment 2

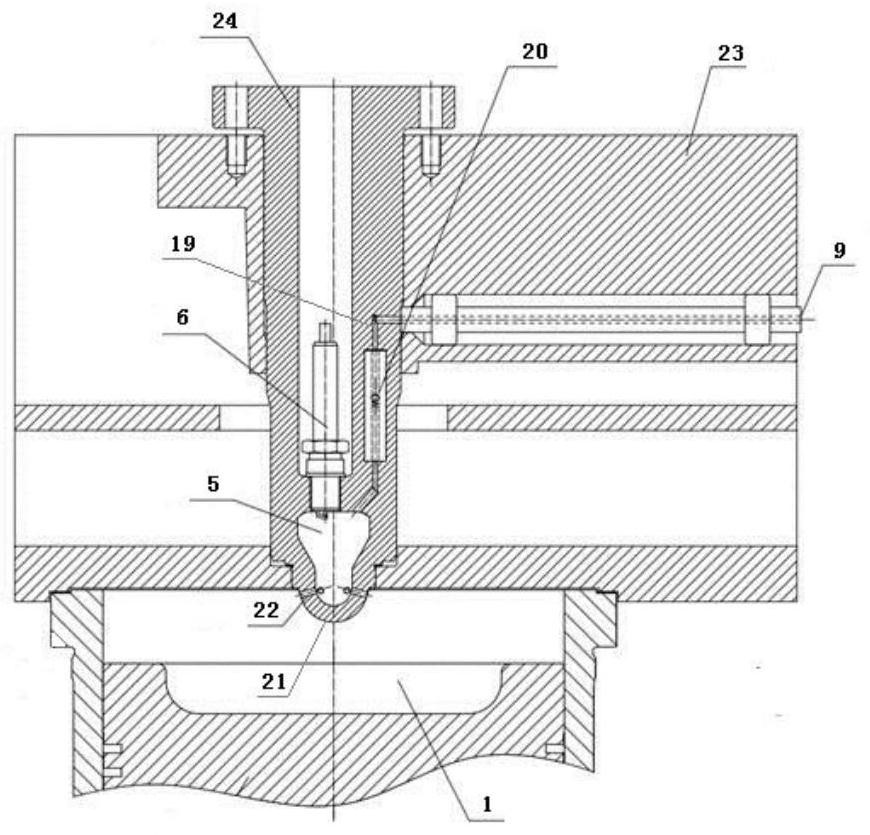

[0066] Embodiment two: if Figure 2 to Figure 8 As shown, a pre-chamber utilizing low-concentration gas includes a pre-chamber combustion chamber 5 and a spark plug, and also includes an intake passage 19 and a one-way control valve 20;

[0067] The intake passage 19 communicates with the pre-chamber combustion chamber 5 through the one-way control valve 20 , and the spark plug is used to ignite the gas inside the pre-chamber combustion chamber 5 .

[0068] In this embodiment, in order to ignite the low-concentration gas in the main combustion chamber 1, an intake passage 19 is provided on the cylinder liner and the spark plug sheath 24, and a pre-combustion chamber intake port 9 is provided outside the intake passage 19. The high-concentration liquefied natural gas is gasified and adjusted to a certain pressure, and then enters the pre-combustion chamber inlet 9, and enters the air intake passage 19, and finally enters the pre-chamber combustion chamber 5 along the air intake...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com