Spray gun cups, receptacles, and methods of use

A receiver and spray gun technology, which is applied to instruments, spray devices, liquid level indicators, etc., can solve problems such as the difficulty of painters, and achieve the effect of easy use and low manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0208] It should be noted that in the drawings, some elements may be present in identical or equivalent multiples; in such a case, one or more representative elements may be designated by reference numerals only, it being understood that such reference numerals The same applies to all such elements.

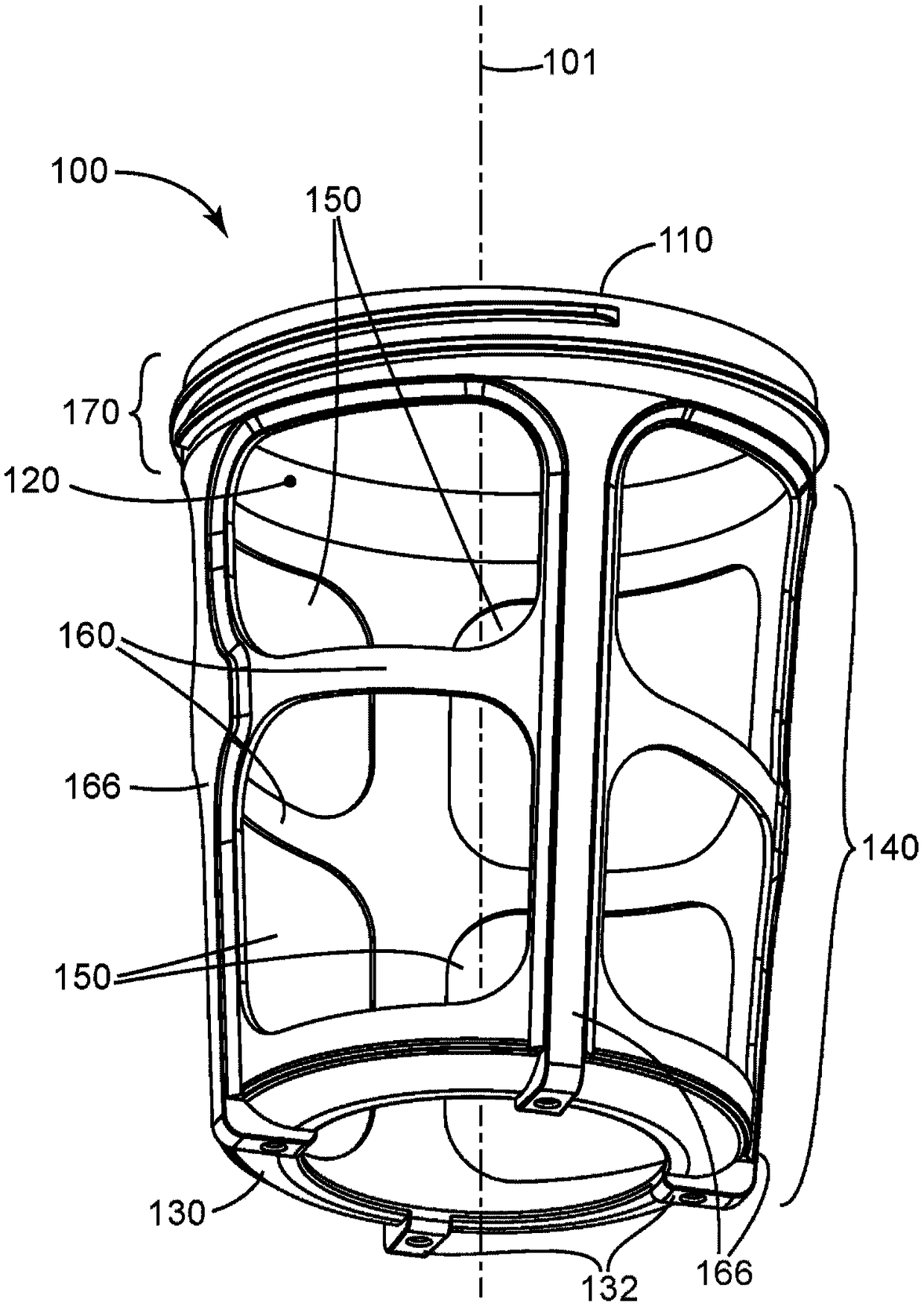

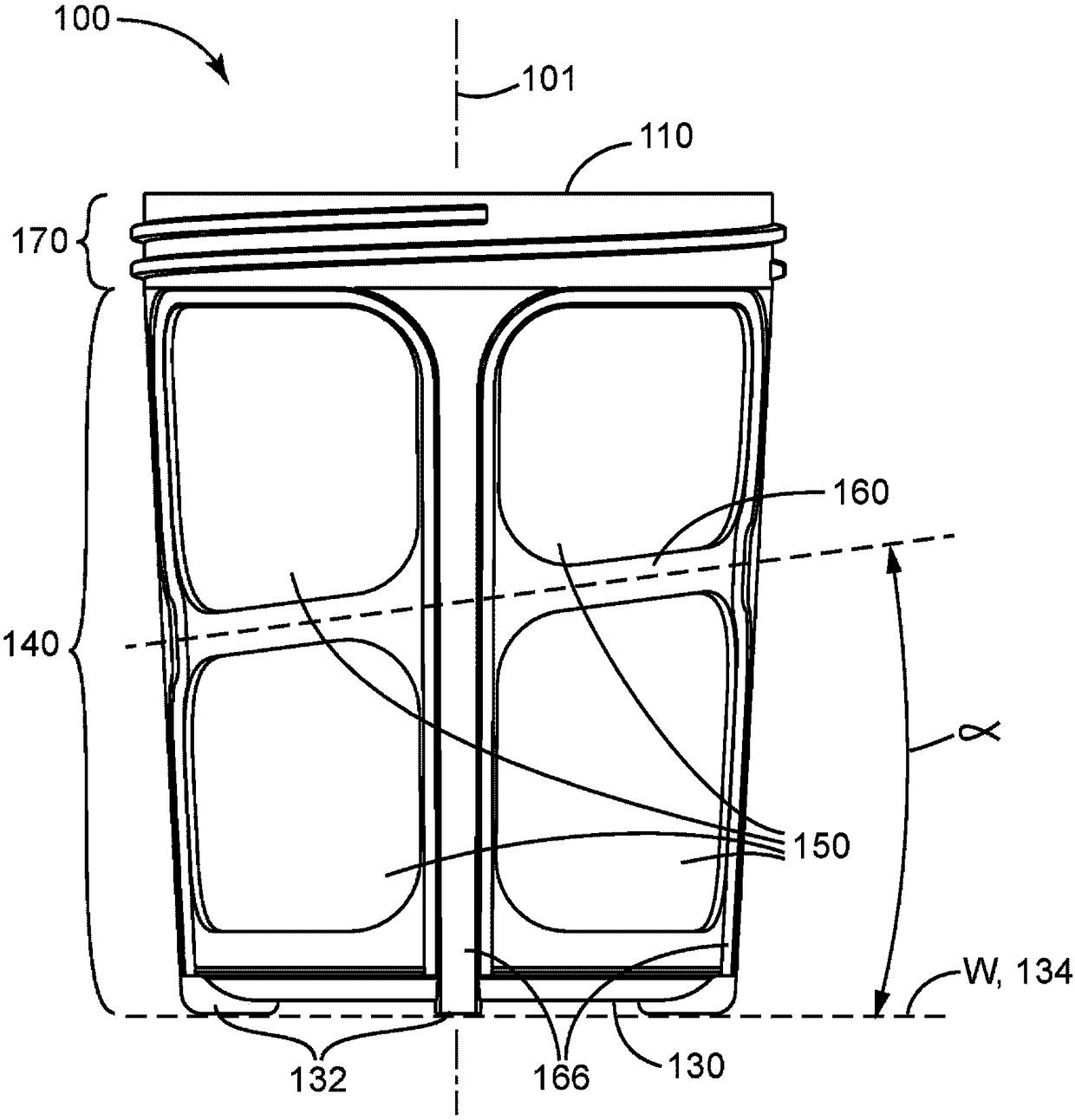

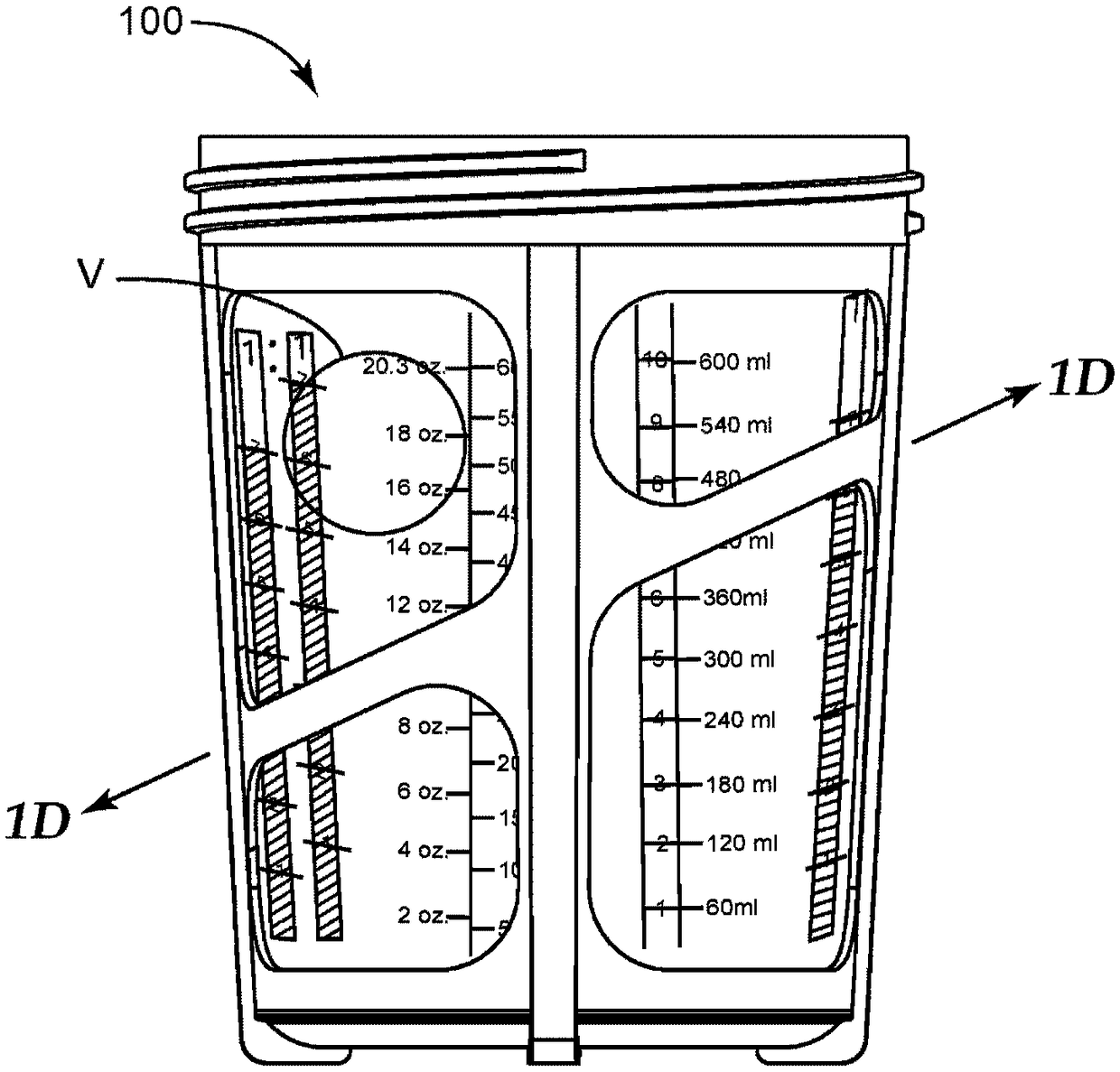

[0209] Figure 1A and Figure 1B An exemplary embodiment of a spray gun cup receptacle 100 according to the present invention is shown. The spray gun cup receiver 100 includes an open end 110 that provides access to an interior cavity 120 . Opposite the open end 110 is a base end 130 . As shown, base end 130 includes a substantially flat configuration with optional feet 132, allowing the base to be stably placed directly on a flat work surface W ( Figure 1A not shown in ). The number, shape and arrangement of the feet 132 can be varied as desired. In some embodiments, the base end 130 is not flat by itself, but can be held stationary on a work surface as described above by m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com