Method for manufacturing glass container

A technology for glass containers and manufacturing methods, applied in glass manufacturing equipment, glass molding, glass blowing molds, etc., can solve problems such as inability to form large bubbles, and achieve stable molding effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0304] 1. Manufacture of glass containers

[0305] (1) Process (A)

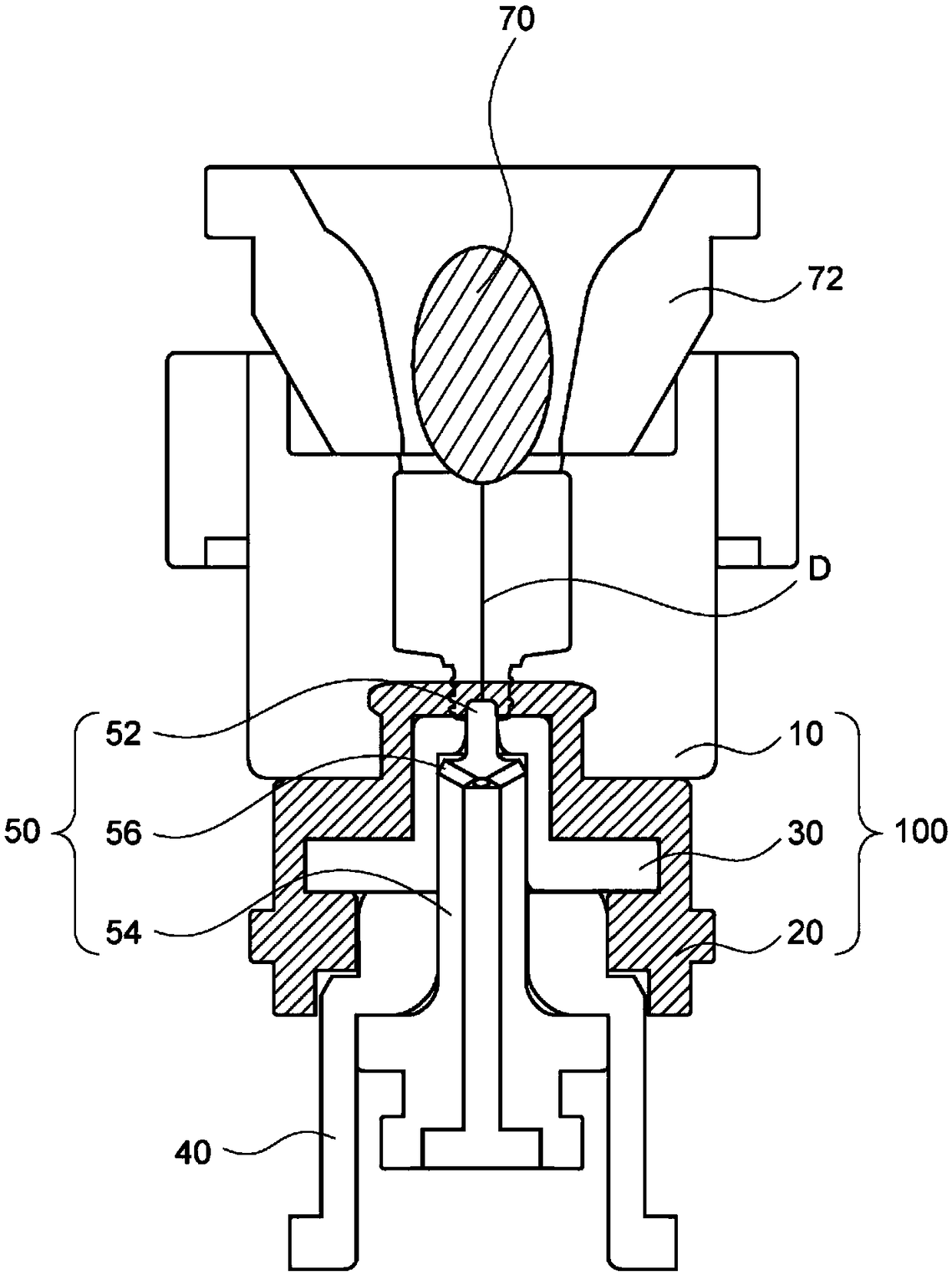

[0306] Such as figure 1 As shown, after fitting the funnel into the molding die, 55 g (950° C.) of soda-lime glass blank was thrown into the molding die through the funnel.

[0307] (2) Process (B)

[0308] Next, if figure 2 As shown, the air is blown into the molding die through the funnel, and after the glass blank is brought into contact with the plunger arranged on the side opposite to the side where the funnel is fitted, the plunger is kept away from the glass blank, and the glass blank is formed on the surface of the glass blank. Recess (circular in plan view, 5.7 mm in diameter, 3.5 mm in depth).

[0309] (3) Process (C)

[0310] Next, if image 3 As shown, after removing the funnel from the molding die, fit the baffle into the molding die.

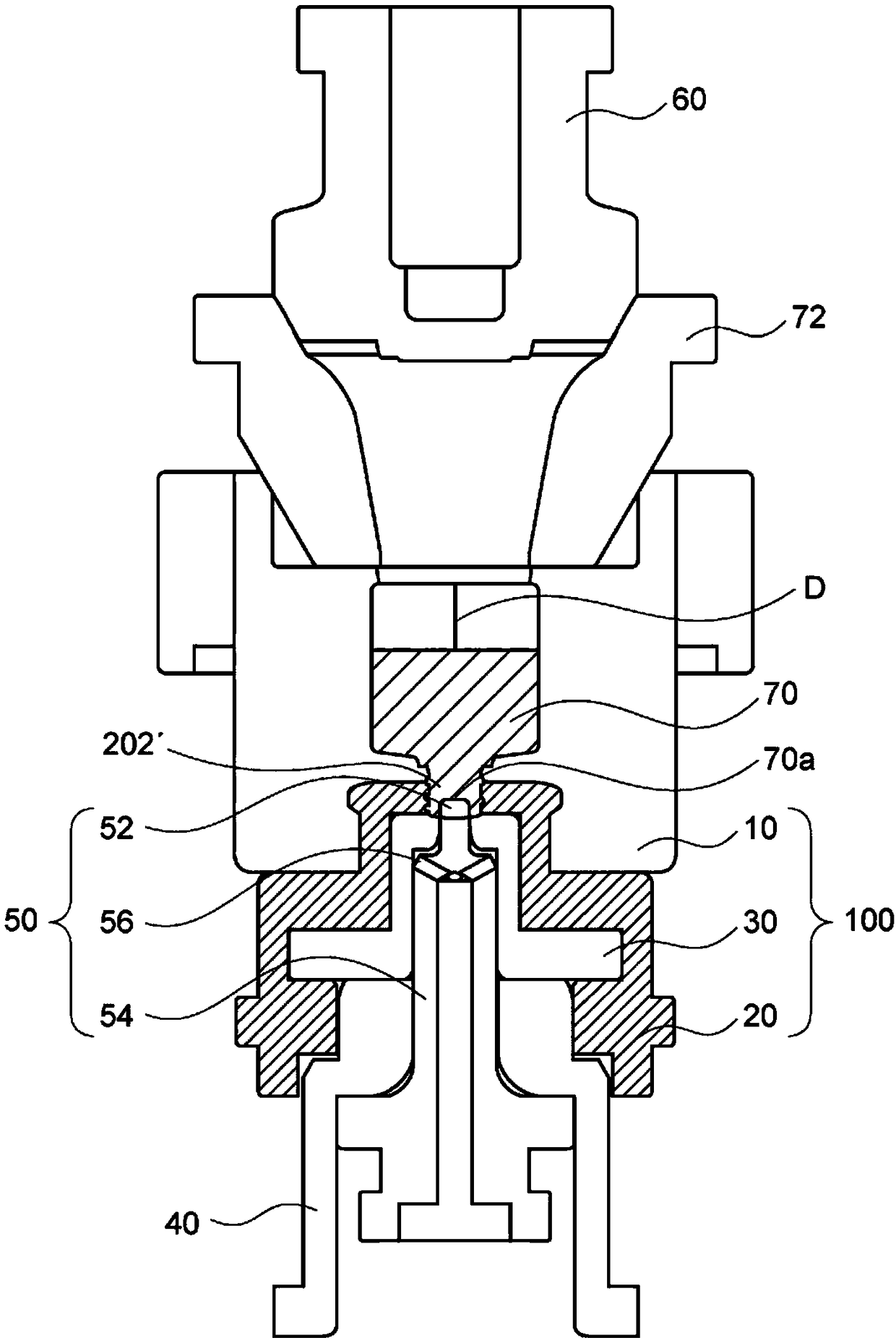

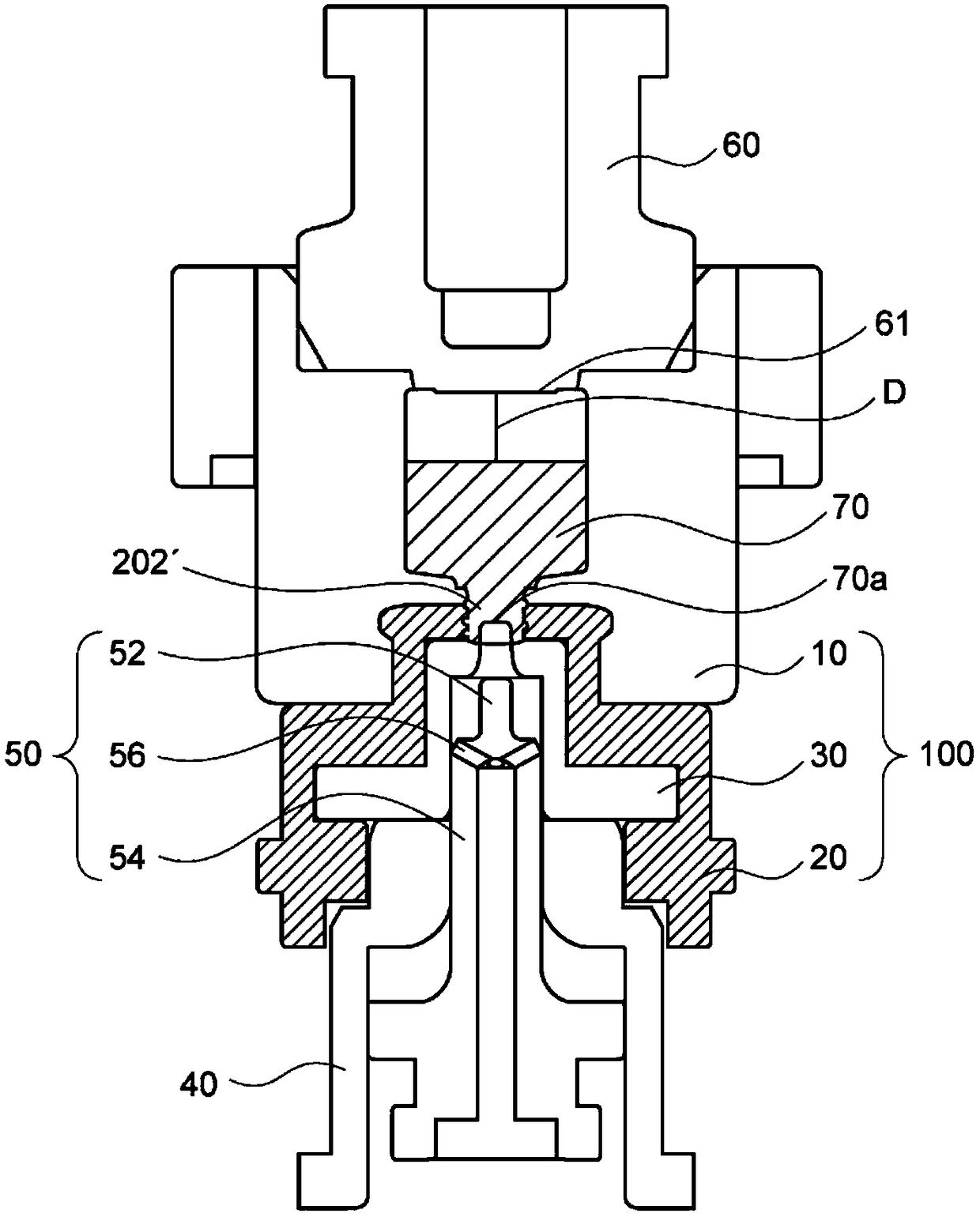

[0311] (4) Process (D)

[0312] Next, if Figure 4 As shown, the air at a pressure of 2.3 kPa is blown out from the plunger for 1.15 seconds to form a ...

Embodiment 2

[0342] In Example 2, except that the weight of the glass blank thrown in in the process (A) was 50.2 g, it carried out similarly to Example 1, and produced and evaluated the glass container. The results obtained are shown in Table 1 and Figure 25 (a) shown.

Embodiment 3

[0344] In Example 3, glass containers were produced and evaluated in the same manner as in Example 1 except that the weight of the glass blank charged in the process (A) was changed to 53.2 g. The results obtained are shown in Table 1 and Figure 25 (b) shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com