Pushing disc for machining steel bars for supporting electric power undermining tunnel

A steel bar and undercover technology, which is applied in the field of steel bar bending, can solve the problems of inconvenient steel bar welding and installation, irregular bending arc, and reduced work efficiency, so as to save manpower, facilitate welding and installation, and improve work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

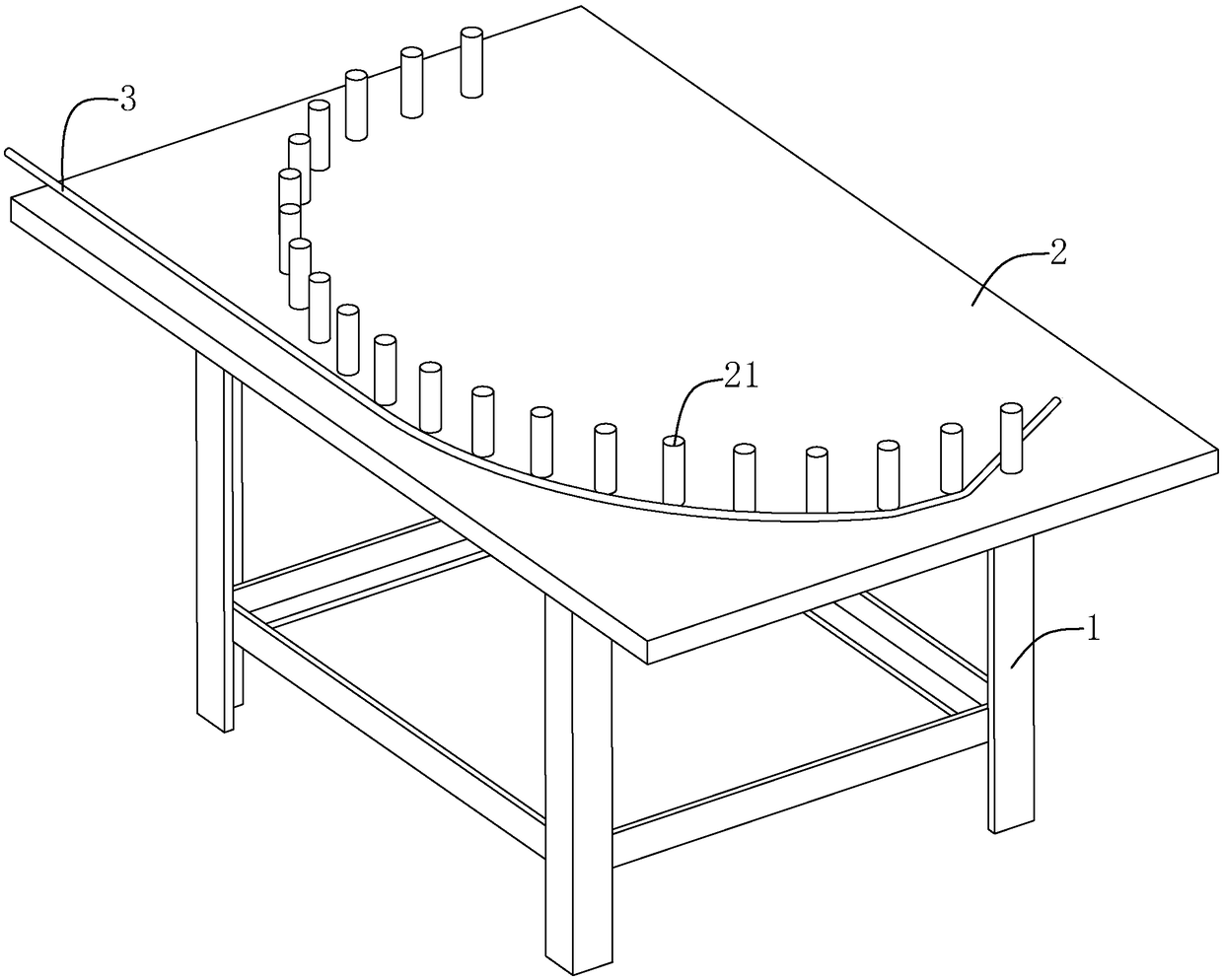

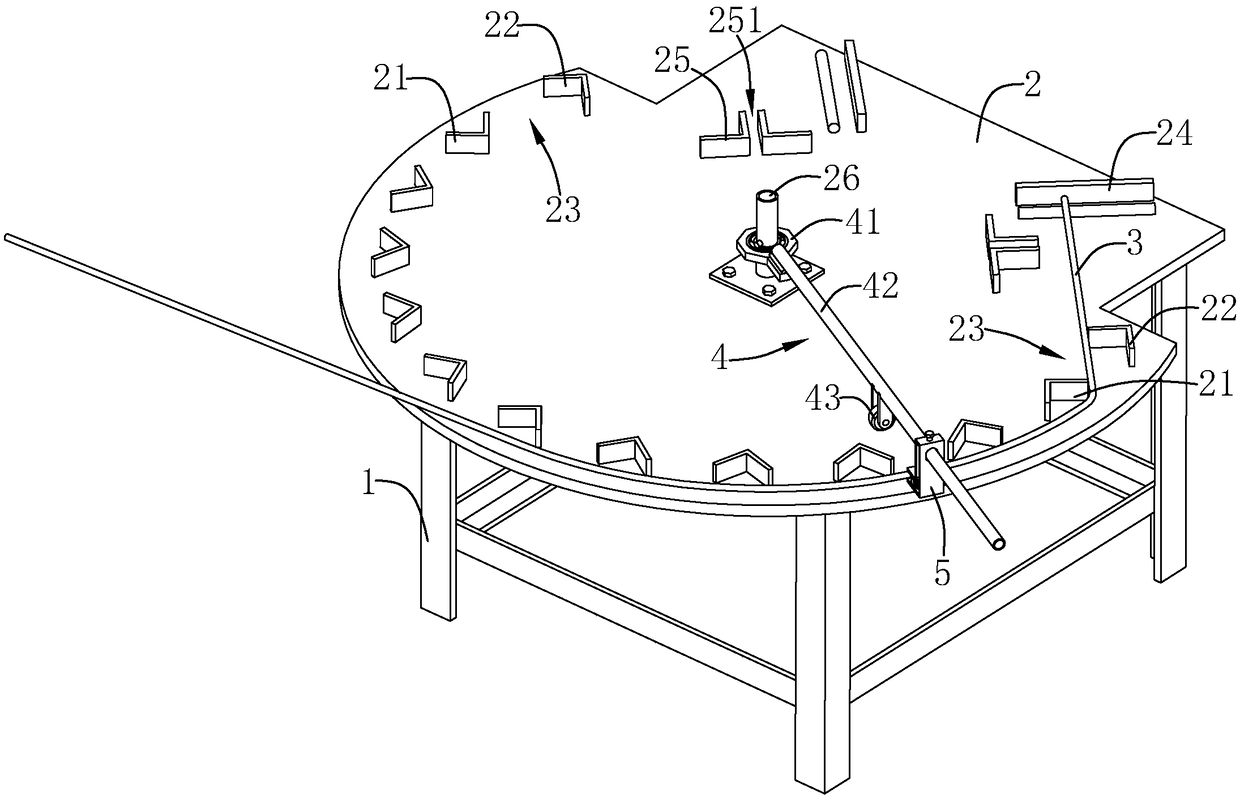

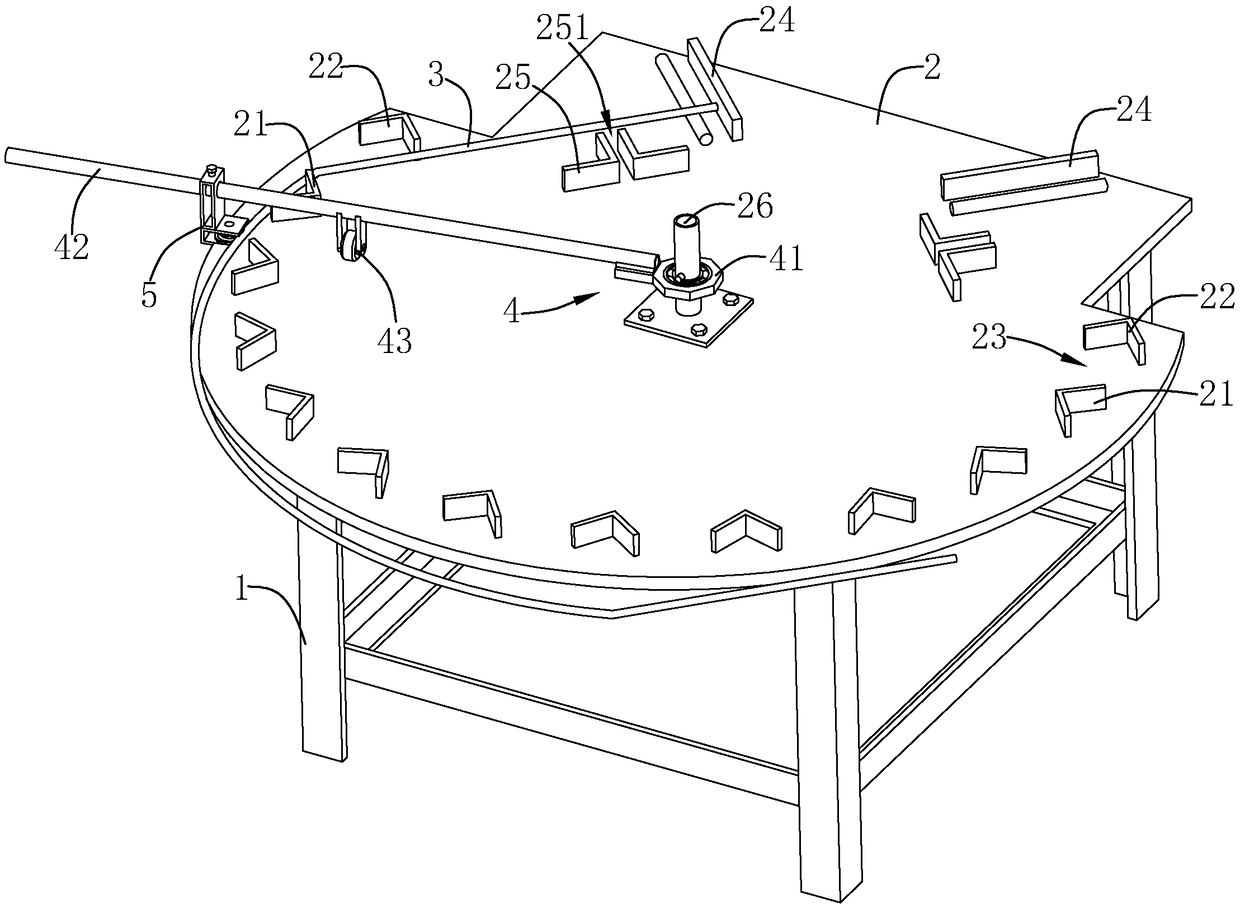

[0041] Embodiment: a kind of push plate used for processing the supporting steel bar of electric power underground excavation tunnel, such as figure 2As shown, it includes a support 1 fixed on the ground. A workbench 2 is horizontally arranged on the support 1. A number of circumferentially distributed moldings 21 are arranged on the upper surface of the workbench 2 at intervals. 21 are respectively provided with a limit piece 22, between the limit piece 22 and the formed part 21 there is a gap 23 for placing the steel bar 3, when the steel bar 3 is placed in the gap 23 between the two, the formed part 21 abuts against the steel bar 3 On one side of the steel bar 3, the limit piece 22 is abutted against the other side of the steel bar 3, and is used to limit and fix the steel bar 3. The center of the circle of several formed parts 21 is rotated and provided with a drive rod 4 extending toward the outside of the workbench 2 to drive The rod 4 is provided with a clamping assemb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com