Pressure casting equipment with organ type radiating pressure casting die

A die-casting mold and organ-style technology, which is applied in the field of die-casting equipment with organ-type heat-dissipating die-casting molds, can solve problems such as difficulty in meeting the production requirements of castings, insufficient fluidity of molten materials, and difficulty in demoulding castings, so as to prevent loosening and ejection Convenience and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

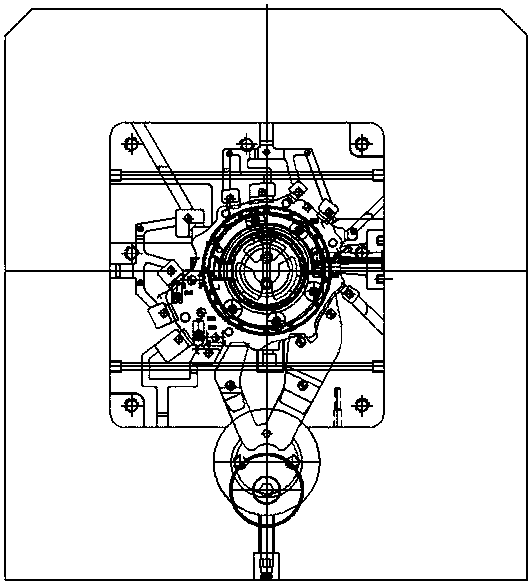

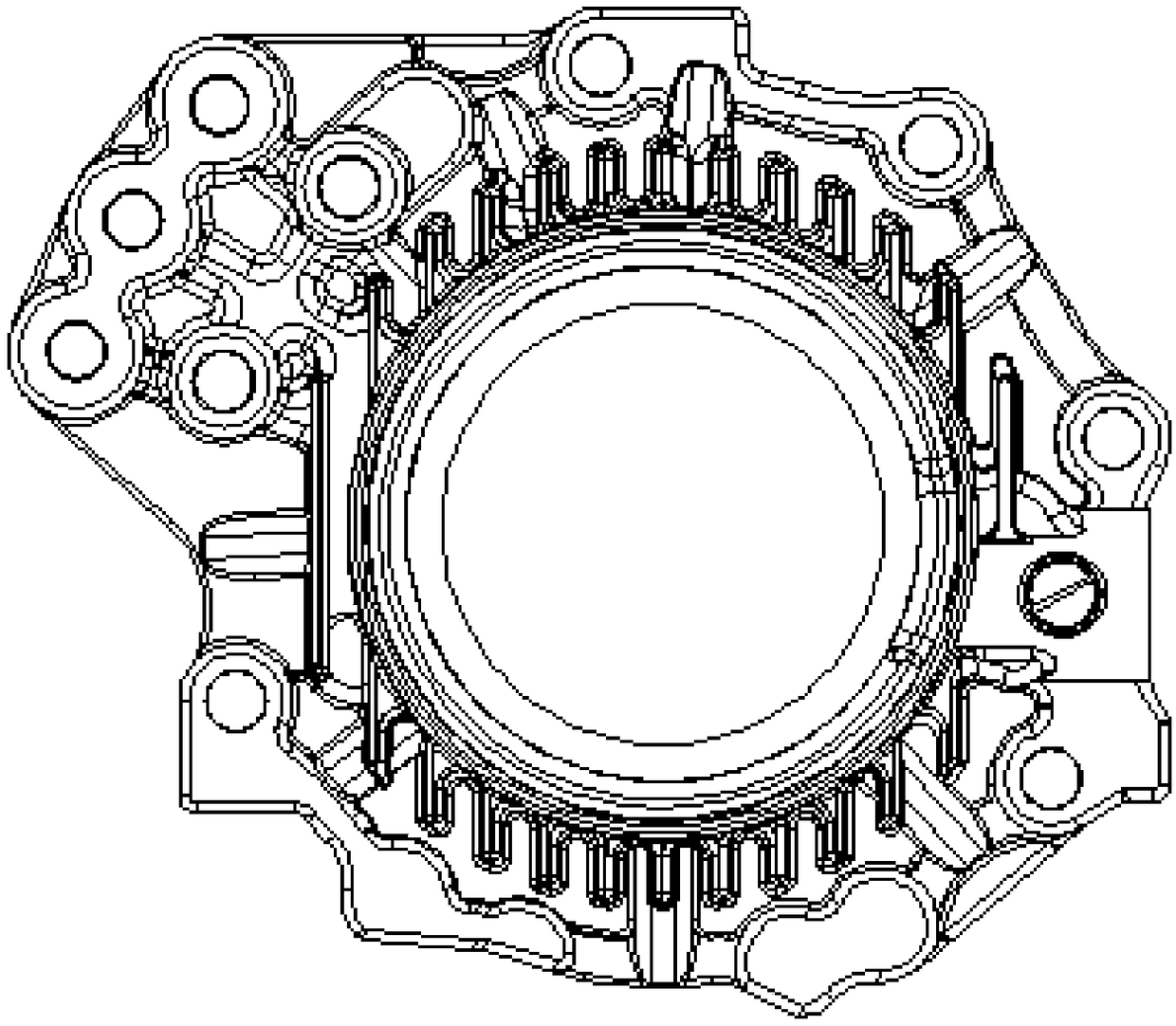

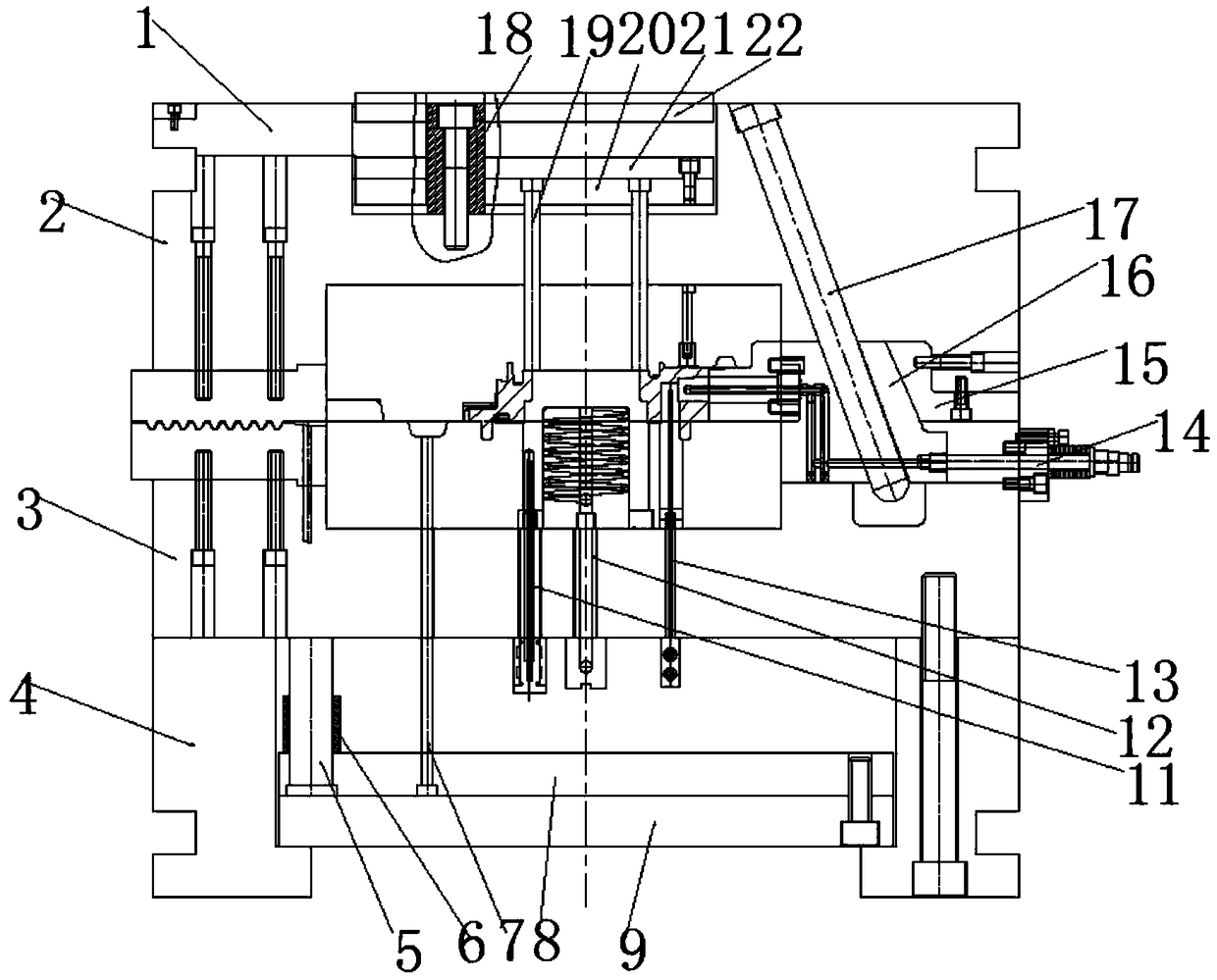

[0018] Figure 1-5 Shown is the relevant explanatory figure of the present invention; The specific embodiment is, as figure 2 , image 3 , Figure 4 , Figure 5 As shown, an organ type heat dissipation die-casting mold includes an upper plate 1, a fixed template 2, a movable template 3, a mold foot plate 4, a top plate reset rod 5, a limit sleeve 6, a runner ejector rod 7, a push plate cover 8, Push plate 9, support column 10, first cooling pipe 11, second cooling pipe 12, third cooling pipe 13, fourth cooling pipe 14, slider pressing block 15, slider body 16, inclined guide post 17, front Die push plate guide column 18, front mold ejector rod 19, front push plate cover plate 20, front push plate 21, front bottom plate 22, front push plate spring 23, front push plate pull rod 24, pressure chamber 25, diverter cone 26, type Cavity insert 27, core insert 28, upper corrugated sheet 29, lower corrugated sheet 30.

[0019] In the mould, the formwork structure components inclu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com